TECHNICAL INFORMATION

The turbine rotor is supported by permanently lu-

bricated high precision ceramic ball bearings in-

stalled on the forevacuum side of the pump.

DESCRIPTION OF THE TURBOPUMP

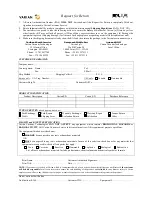

The Turbo-V550 pump is available in four versions

which differ only in their inlet flange.

They are:

The static blades of the stator are made of

stainless steel. These are supported and accu-

rately positioned by spacer rings.

−

Model 969-9047 with ISO 100 high vacuum

flange

The Macrotorr stators are in the form of self-

positioning machined discs with pumping channels

and an opening restricted by the corresponding

rotor discs. These are made of aluminium alloy.

−

Model 969-9048 with ConFlat 6” external di-

ameter high vacuum flange

−

Model 969-9049 with ISO 160 high vacuum

flange

During normal operation, the motor is fed with a

voltage of 56 Vac three-phase at 700 Hz. To re-

duce losses during start-up to a minimum, the fre-

quency increases according to a ramp with a

higher initial voltage/frequency ratio.

−

Model 969-9050 with ConFlat 8” external di-

ameter high vacuum flange

Model 969-9047

Model 969-9048

Model 969-9049

Model 969-9050

The external body of the pump is shaped so that

the pump can function with natural convection air

cooling. Kits are available for water cooling or

forced air cooling to cool the pump in the cases

where it is used under heavy load or when natural

convection is insufficient for cooling purposes.

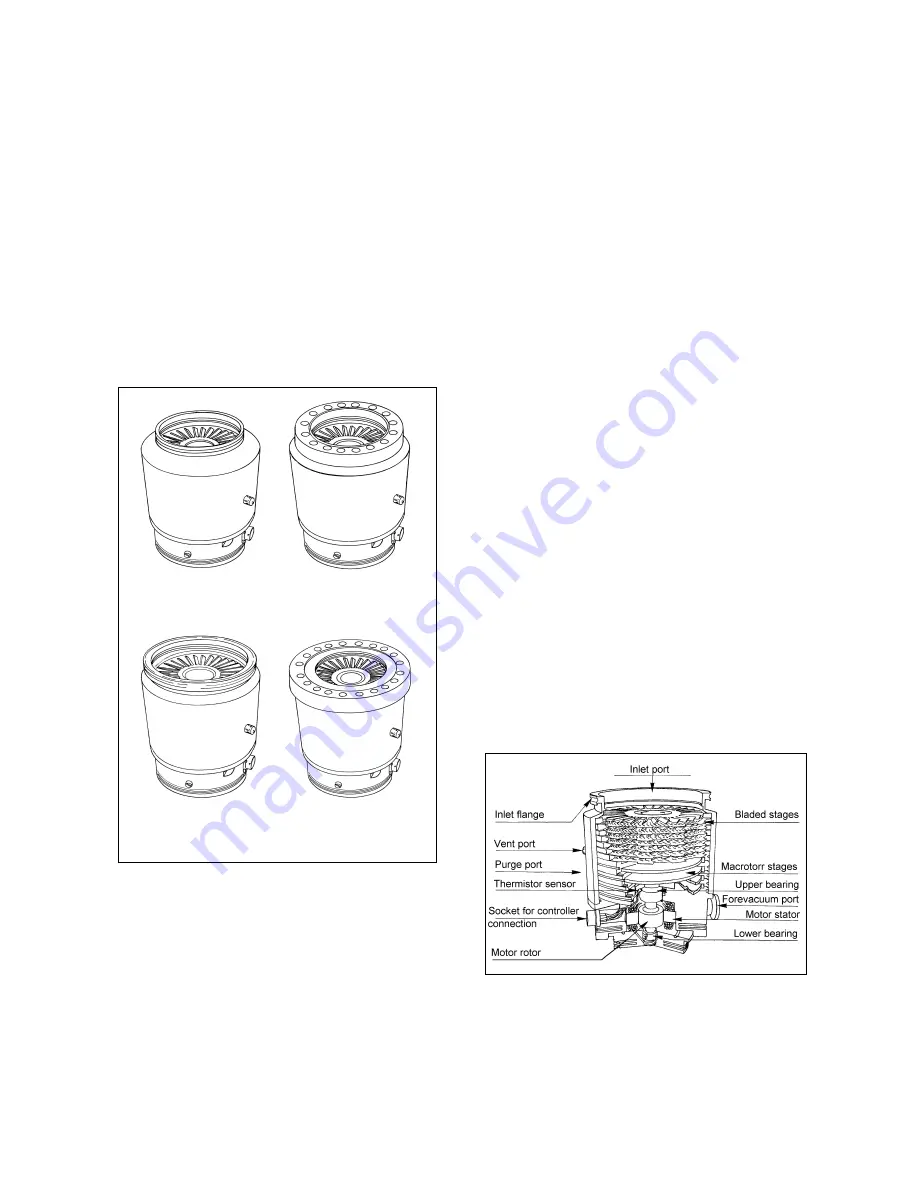

A thermistor sensor is mounted near the upper

bearing to prevent the pump from overheating.

The thermistor sensor, the motor stator windings

and the earth are connected to a Turbo-V control-

ler through a 8 pin socket on the side of the pump.

The pump is balanced after assembly with a resid-

ual vibration amplitude less than 0.01

µ

m.

The pump can operate in any position and can be

supported on the high vacuum flange or on its

base. The connection of the forevacuum on the

side of the pump is a KF 25 NW flange.

The Turbo-V550 pump consists of a high fre-

quency motor driving a turbine fitted with 8 bladed

stages and 4 Macrotorr stages. The turbine rotates

in an anticlockwise direction when viewed from the

high vacuum flange end.

The turbine is made of high-strength, light alumin-

ium alloy, and is machined from a single block of

aluminium. The turbine blades have six different

angles, from 40

°

to 16

°

, while the Macrotorr stages

are in form of discs.

25

87-900-874-01(B)