INSTRUCTIONS FOR USE

4

87-900-847-01 (B)

GENERAL INFORMATION

This equipment is destined for use by professionals.

The user should read this instruction manual and any

other additional information supplied by Varian before

operating the equipment. Varian will not be held

responsible for any events occurring due to non-

compliance, even partial, with these instructions,

improper use by untrained persons, non-authorised

interference with the equipment or any action contrary

to that provided for by specific national standards.

The following paragraphs contain all the information

necessary to guarantee the safety of the operator when

using the equipment. Detailed information is supplied in

the "Technical Information".

This manual uses the following standard protocol:

!

The warning messages are for attracting the attention

of the operator to a particular procedure or practice

which, if not followed correctly, could lead to serious

injury.

CAUTION!

The caution messages are displayed before

procedures which, if not followed, could cause damage

to the equipment.

NOTE

The notes contain important information taken from the

text.

STORAGE

When transporting and storing the devices, the

following environmental requirements should be

satisfied:

•

temperature: from -20 °C to + 70 °C

•

relative humidity: 0 - 95%

(without condensation)

PREPARATION FOR INSTALLATION

The device is supplied in a special protective packing.

If this shows signs of damage which may have

occurred during transport, contact your local sales

office. When unpacking the Hand-held terminal, ensure

that it is not dropped or subjected to any form of

impact. Do not dispose of the packing materials in an

unauthorized manner. The material is 100% recyclable

and complies with EEC Directive 85/399.

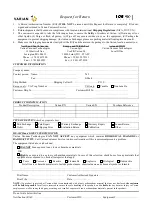

Hand-held Terminal Controls, Indicators and

Connectors

The following paragraph illustrates the Hand-held

terminal panel. More details are contained in the

appendix "Technical Information".

1.

Keyboard push-button for LOW SPEED mode

selection. It is active only when the front panel

operation has been selected. Pressed once, the pump

runs at about 2/3 of the nominal speed. To unselect the

mode, press the push-button again.

2.

Keyboard push-button for START, STOP, RESET

mode selection. It is active only when the front panel

operation has been selected. By pressing once the

starting phase begins; if pressed again it stops the

pump. If the pump has been stopped automatically by

a fault, this push-button must be pressed once to reset

the device

and a second time to restart the pump.

3.

Keyboard push-button to recall on the display the cycle

number, cycle time and pump life.

4.

Keyboard push-button to recall on the display the pump

current, pump temperature, pump power and rotational

speed. It is always active regardless of the operating

mode selected. Push-buttons 3 and 4, if pressed

together for at least 2 seconds, put the device in a

routine where it is possible to program some operation

parameters.

5.

LCD back-lighted alphanumeric display: dot matrix 2

lines x 16 characters.

Hand Held Terminal Front Panel

NOTE

LOW SPEED and START/STOP RESET functions are

active only if the FRONT panel mode of operation is

selected (see "Technical Information").

WARNING!