M

AINTENANCE

1041 Injector

CP-3800 GC Getting Started Manual

63

Gas Leak

Checking

A convenient and non-contaminating way to leak test fittings and connections

after installation or hardware replacement procedures is to direct a small jet

of gas (butane from a disposable lighter recommended for flame ionization

detectors) at the point to be tested, then use the detector, at maximum

sensitivity, to detect leakage of gas into the system. Use normal column flow,

a cool oven, and an operational detector. If a peak is detected in excess of

the magnitude given in the following table, repair the leak.

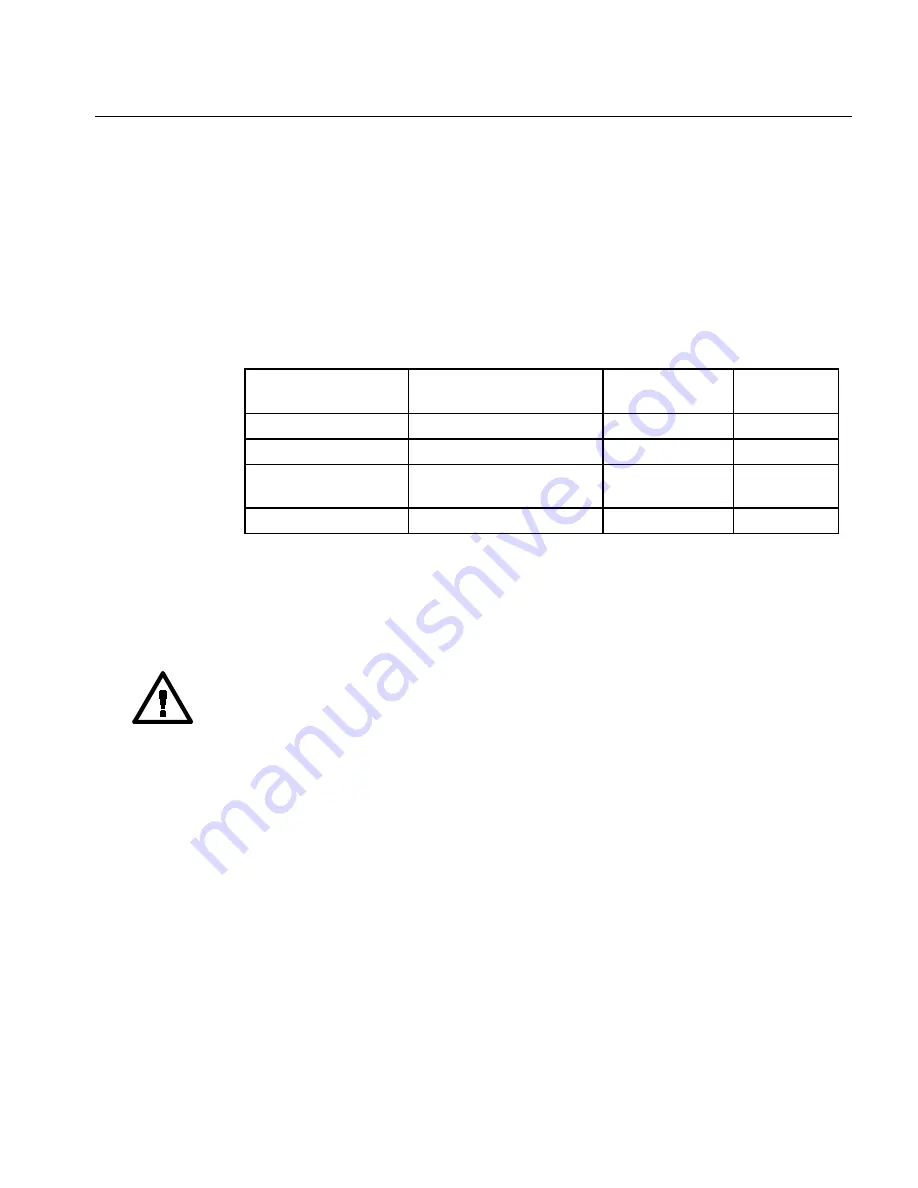

Detector

Gas

Attenuation,

Range

Maximum

Peak Size

FID

Butane

16 x 10

-12

30%

ECD

Dichloromethane

2 x 1

50%

PFPD, Sulfur Mode

Natural Gas containing

methanethiol

2 x 10

-10

50%

TSD

Dichloromethane

2 x 10

-12

2%

Visual Leak

Checking

The least preferred method of leak checking is to place a drop of pure

solvent (isopropyl alcohol recommended) on the suspected fitting or

connection and look for bubbles.

C A U T IO N

Commercial soap type leak detection fluids should not be used at

any point in a capillary system, since, if a leak is present, the fluid

will penetrate and contaminate the system. Column performance

will be degraded and a substantial period of time may be

required to achieve a clean system.

Syringe Leak

Checking

In some instances, non-reproducible chromatographic responses can be

attributed to a worn and/or leaky syringe. The syringe must be leak tight. To

check the syringe, insert the needle in an injector operating at 20 to 30 psig

with a no-hole ferrule. Place a drop of solvent at suspect leak locations and

look for bubbles.