100

03-914648-00:7

ACTIVE

METHOD

EDIT

METHOD

CTRL

RUN

TIME

END

TIME

Method 1

Method 1

0.00

20.00

Set(°C): 250, Actual(°C): 250

MIDDLE 1061

1061 Oven Power

ON

1061 Temperature

250

Electronic

Flow Control

Operation

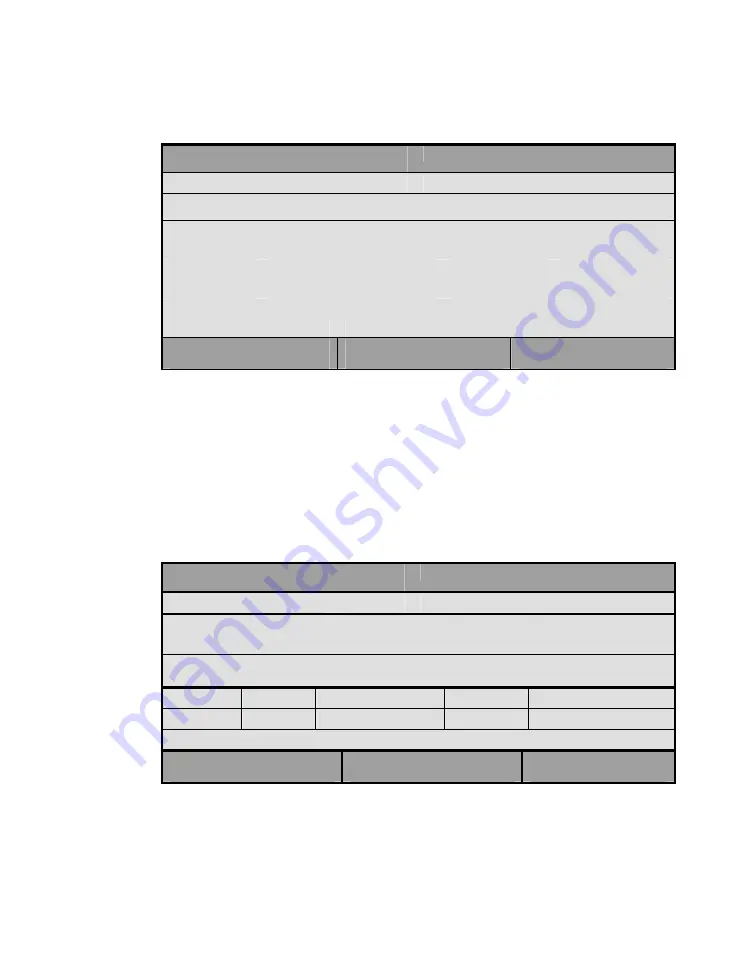

With EFC installed there is one additional screen to configure accessed by

pressing the FLOW/PRESSURE key. Type 3 EFC allows the user to set a

constant flow or to program the flow. The status field displays the column

pressure, actual flow and column linear velocity. Note that type 3 actually

sets a required carrier flow into the injector/column system. A leak in the

system would be indicated to the user by a drop in inlet pressure.

ACTIVE

METHOD

EDIT

METHOD

CTRL

RUN

TIME

END

TIME

Method 1

Method 1

0.00

20.00

Col Press: 5.0 psi, Col Flow: 10.0 mL/min,

Linear Vel: 125 cm/sec

MIDDLE EFC Type 3

Step

Flow

Rate

Hold

Total

Initial

10.0

-

20.00

20.00

The screen above represents a typical application of type 3 EFC with an

isothermal injector. Normally this type of injection system is maintained at

constant flow during the analytical run. However, if required the column flow

rate could be programmed during the run.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com