118

03-914648-00:7

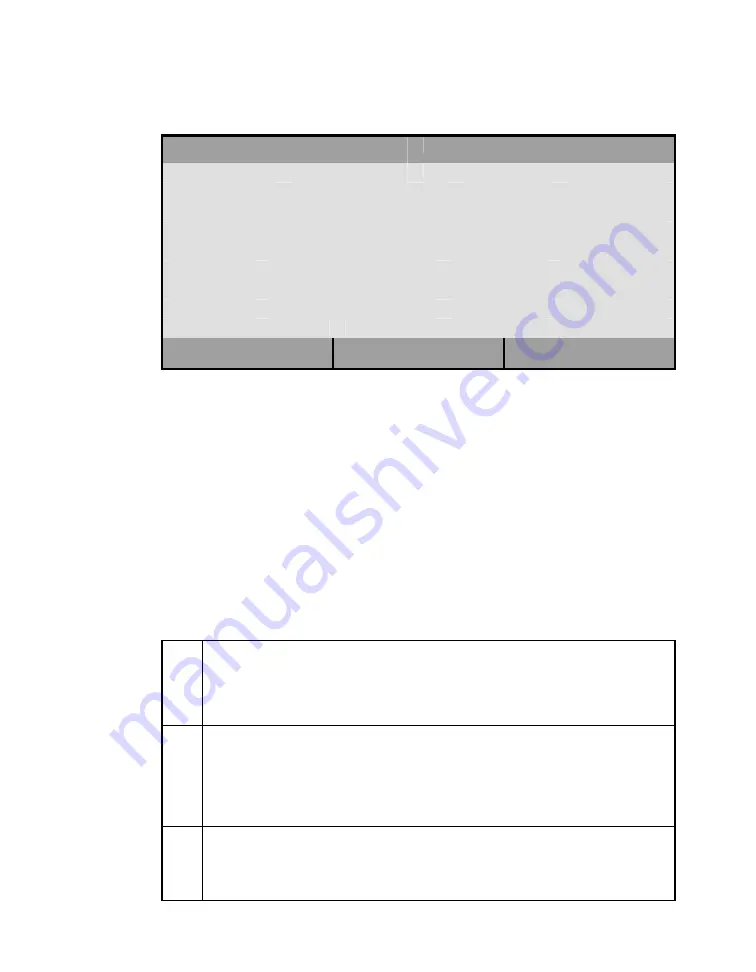

The second Adjustments page is only accessible if detector EFC is installed.

ACTIVE

METHOD

EDIT

METHOD

CTRL

RUN

TIME

END

TIME

Method 1

Method 1

0.00

20.00

Make-up Flow (ml/min): 25 H

2

Flow (ml/min): 2.5

Air Flow (ml/min): 175

MIDDLE TSD ADJUSTMENTS, Page 2 of 2

Make-up Flow (ml/min)

25

H

2

Flow (ml/min)

4.5

Air Flow (ml/min)

175

Optimization

of the TSD

Using the

Varian Test

Sample

The sensitivity of the TSD is highly dependent on bead temperature and the

selectivity is dependent on hydrogen flow. In addition, there are slight

variations from bead to bead and a bead changes slowly as it ages.

Therefore, optimum operating conditions for a given TSD cannot be

specified exactly; the user should determine optimum operating conditions

for the application and TSD bead.

The detector responds to both nitrogen and phosphorus. It is not possible to

significantly change the relative response of nitrogen to phosphorus.

Determining

Optimum

Hydrogen

Flow

Although a nominal hydrogen flow of 4.0 mL/min is suggested, the nitrogen-

to-carbon selectivity versus hydrogen flow often differs slightly from bead to

bead. Consequently, for each new bead it is useful to chromatograph the

detector test sample at several values of hydrogen flow (from 4 to 5.5

mL/min) to determine the best hydrogen flow for that bead.

1

Zero the TSD signal. Inject 1 µL of TSD test sample (82-005048-04). A

normal response will result in the bead quenching during the solvent peak

(i.e., a negative deflection of the pen will occur), and a positive response for

the azobenzene, heptadecane, methyl parathion, and malathion peaks.

Adjust the detector range to keep the peaks on scale.

2

If the azobenzene peak (see the appropriate chromatogram below) is less

than 3 times the height of the heptadecane peak, decrease the hydrogen

flow rate and re-inject the sample. If injection of the test sample results in

quenching by the solvent peak and the bead fails to re-ignite, simply

increase the bead current slowly, with intervening pauses of ~15 minutes,

until the bead re-ignites. Then repeat step 1.

3

Over the next few days, the background current of the bead will decrease,

and the sensitivity will also decrease to a steady level. At this point the

sensitivity of the bead will remain relatively constant, with low baseline drift,

and low noise.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com