38

03-914648-00:7

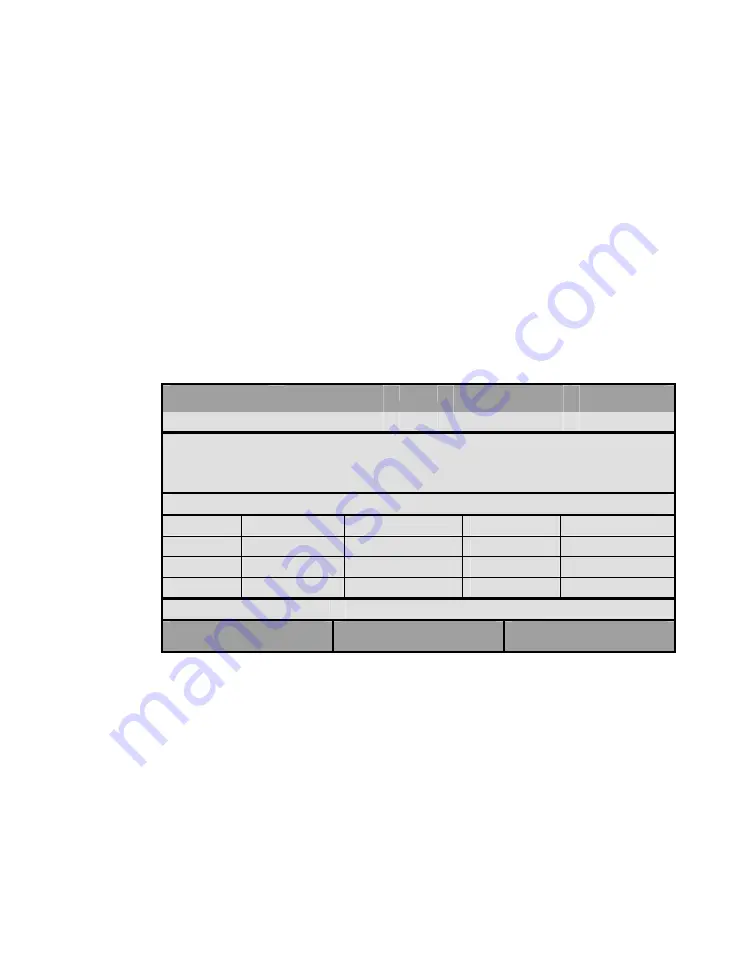

Type 1 EFC

Type 1 EFC, used with the either the CP-1177 or 1079 injector, allows you to

maintain a constant pressure or to build a pressure program to maintain

constant column flow while temperature programming the column oven.

An example of a Type 1 EFC method is shown below. The status field

displays the column head pressure (in the units chosen in Setup), calculated

column flow rate, calculated column linear velocity, total flow and split ratio

status. Total flow represents the column flow septum purge flow and the split

vent flow. The split ratio status is either off if the split state is set to OFF, or a

whole number. Additionally, the table below is a typical pressure program

used in conjunction with a column oven temperature program to maintain

constant flow.

ACTIVE

METHOD

EDIT

METHOD

CTRL

RUN

TIME

END

TIME

Method 1

Method 1

0.00

20.00

Col Press (psi): 10.0

Col Flow (mL/min): 2.0

Linear Vel. (cm/sec): 3.5

Total Flow (mL/min): 50

Split Ratio: Off

FRONT EFC Type 1 Page 1 of 2

Step

Pres (psi)

Rate (psi/min) Hold (min)

Total (min)

Initial

10.0

-

0.75

0.75

1

20.0

2.00

2.00

5.75

2

35.0

5.00

5.25

14.00

Constant Flow Programming

The second page of the TYPE 1 EFC allows constant flow mode to be

selected. Selecting Constant Flow will allow you to set a Pressure Pulse

program accessed via the Pressure Pulse softkey that will be displayed once

you have selected Constant Flow. When Constant Flow Programming is

enabled, a pressure program based on the column parameters and the

column oven temperature program will be built whenever the method is

activated. If the desired column flow, or the column oven temperature

program is changed, the method must be reactivated to derive a new

pressure program for these new conditions.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com