CP-3800 GC Operator’s Manual

41

Type 4 EFC

Type 4 EFC is used with valved systems where the inlet head pressure will

typically be kept constant, but the total flow can be changed to maintain this

head pressure in the event of a sudden drop in system pressure (as is usual

when a sample at atmospheric pressure is loaded into the system).

Pressure programming the inlet head pressure, similar to type 1 EFC, is also

possible to maintain a constant column flow rate during a column oven

temperature program. The programming of type 4 EFC is done on 2 pages

(see below). Page 1 includes a ramp table for programming the inlet

pressure. Page 2 is a timed events table for setting the total flow rate. In this

example the column head pressure is held constant during the analytical run,

but the total flow into the system is increased significantly at the beginning of

the run to allow the system to respond more rapidly to pressure transients by

sampling valve actuation.

ACTIVE

METHOD

EDIT

METHOD

CTRL

RUN

TIME

END

TIME

Method 1

Method 1

0.00

20.00

Col Press (psi): 10.0 Col Flow (mL/min): 15

Linear Vel. (cm/sec): 125 Total Flow (mL/min): 30

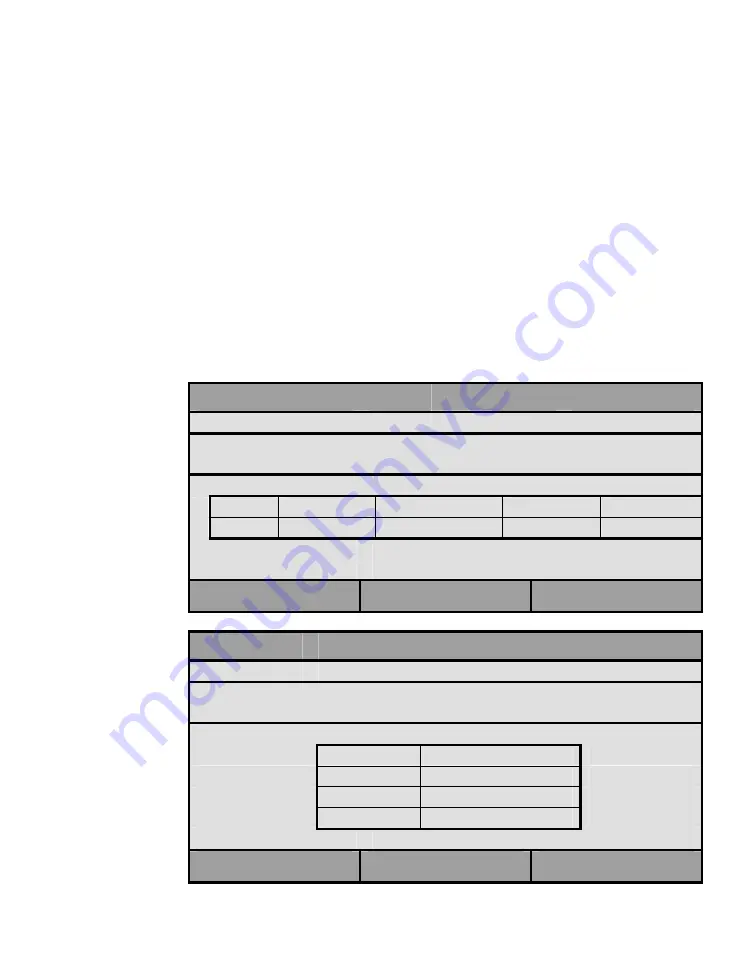

REAR EFC TYPE 4, Page 1 of 2

Step

Pres (psi)

Rate (psi/min)

Hold (min)

Total (min)

Initial 10.0

-

20.00

20.00

ACTIVE

METHOD

EDIT

METHOD

CTRL

RUN

TIME

END

TIME

Method 1

Method 1

0.00

20.00

Col Press (psi): 10.0 Column Flow (mL/min): 15

Linear Vel. (cm/sec): 125 cm/sec Total Flow (mL/min): 30

REAR EFC Type 4, Page 2 of 2

Time

Total Flow (mL/min)

Initial

30

0.00

100

0.50

30

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com