CP-3800 GC Operator’s Manual

65

1177 Modes of Operation

The 1177 can be operated in several modes, depending on the nature of the

sample and requirements of the analysis. When designing an injection

method the most important parameters are:

•

the injector insert used;

•

the injector and column temperature when the injection is made;

•

the carrier gas flow profile through the injector.

The following is a brief description of the method parameters used for each

injection mode. In all cases Electronic Flow Control is used for carrier gas

control.

Note

: In many cases switching from one 1177 mode to another involves

changing the glass insert. A detailed stepwise procedure to carry out this task is

given in the Maintenance section of the 3800 Getting Started manual. In most

injection modes the insert is installed with an o-ring.

Split

Injection

The split mode is used when samples are relatively concentrated and for

neat samples. This mode of injection involves rapid vaporization of the

sample followed by sample splitting. Splitting involves directing a portion of

the sample into the column while the remainder is vented. The split ratio is

defined as the proportion of sample vented to the sample entering the

column. With EFC carrier gas control this parameter can be set

automatically in the 1177 method.

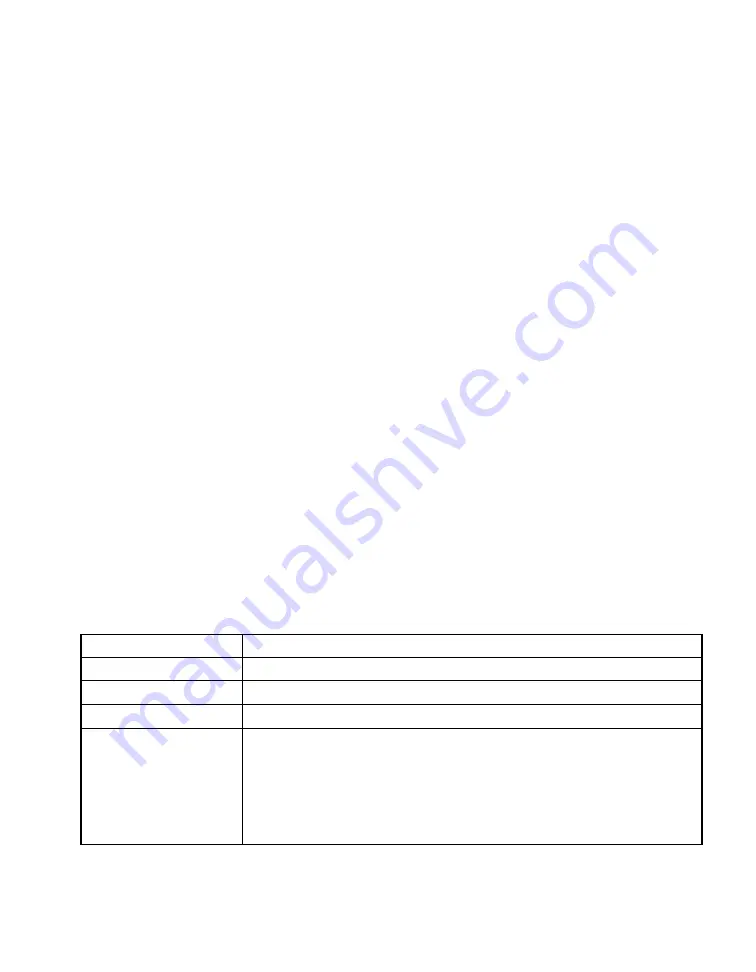

Table 4 Split Injection Typical Conditions

Injector Insert

4 mm ID open insert packed with glass wool

Column Installation

3.7 cm from the bottom of the column nut at the base of the injector

Injector Temperature

Isothermal 250

°

C.

Column Temperature

50

°

C initial for 0.1 min, ramp to 250

°

C at 20

°

C/min, hold 5 min.

Carrier Gas Control

Set the split mode to ON for the duration of the run in the 1177 method

section, and set the split ratio to 100. The sample will be split upon

injection and a representative portion representing 1/100

th

of the amount

injected will enter the column. Note that the split ratio is a method specific

parameter and should be set appropriately for individual analyses. In

addition the injector pressure or pressure ramp should be set to achieve

the desired column flow rate.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com