84

03-914648-00:7

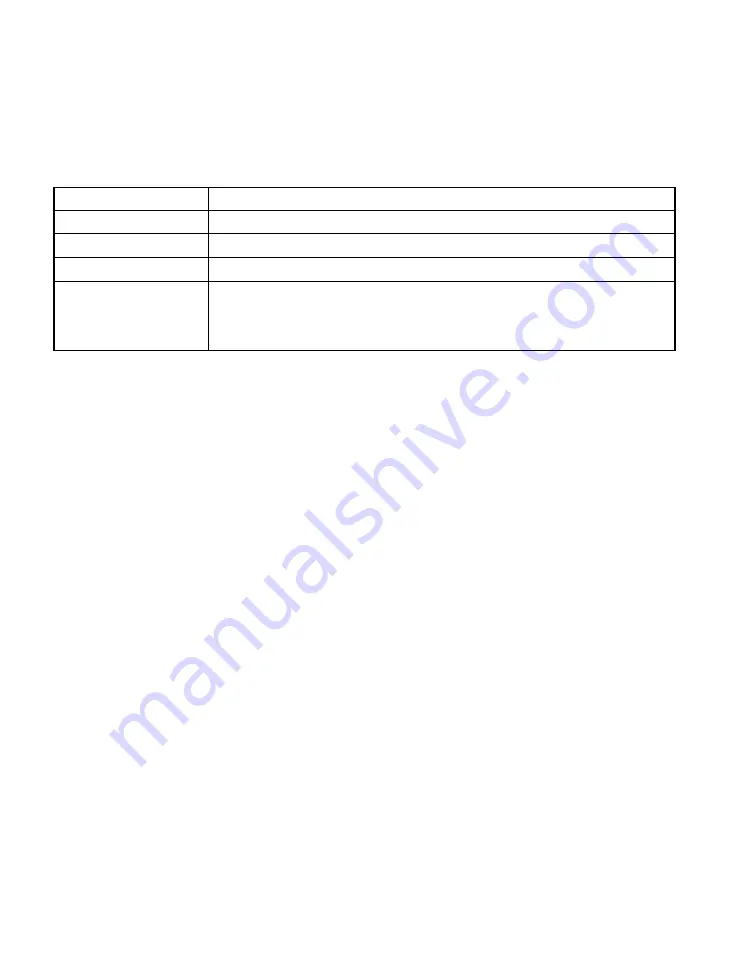

The following table describes typical method parameters for an isothermal

splitless injection.

Table 10 Isothermal Splitless Injection Method Parameters

Injector Insert

Install the standard 3.4 mm ID splitless insert (P/N 03-926119-45).

Column Position

7.5 cm from the bottom of the column nut at the base of the injector.

Injector Temperature

Initial temperature isothermal 250

°

C.

Column Temperature

50

°

C initial for 1 min, ramp to 250 °C at 20

°

C/min, hold 5 minutes.

Carrier gas control

Set the initial split mode to OFF and time program it to ON after 0.75

minutes. In this case the splitless sampling time is 0.75 minutes. The split

ratio during the split ON period should be set to 50. Set the appropriate

pressure or pressure ramp to achieve the desired column flow rate.

Temperature

Ramped

Splitless

Injection

This is a similar technique to isothermal splitless except the sample is

vaporized slowly, utilizing temperature programming. This controlled

mode of vaporization reduces the risk of mass discrimination and thermal

breakdown of sample components during the sampling period. The

sample is deposited in the injector as a liquid, therefore the initial injector

temperature must be close to the solvent boiling point and there must be a

nearby surface for the sample to be retained on. For this mode of injection

either a narrow bore (0.5 mm) insert or a glass wool packed insert is used.

This facilitates efficient transfer of the sample to a surface from which it is

then vaporized.

Note that the glass wool packet insert is not recommended for low levels of

polar analytes.

The following are typical method parameters for a temperature ramped

splitless injection. In this example hexane is used as the solvent which has

a boiling point of 68 °C. Note that the sampling time and initial column hold

time are 2 minutes to allow the injector get to maximum temperature.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com