FRG-700 Inverted Magnetron Pirani Gauge

14

4 Operation

As soon as the required supply voltage is applied, the measuring signal is available

between pins 3 and 5. (

→

Appendix for the relationship between the measuring

signal and the pressure).

Allow for a stabilizing time of approx. 10 min. Once the gauge has been switched

on, permanently leave it on irrespective of the pressure.

The gauge consists of tow separate measuring systems (Pirani and cold cathode

system according to the inverted magnetron principle). They are combined in such

a way that for the user, they behave like one measuring system.

The optimum measuring configuration for the particular pressure range, in which

measurement is performed, is used:

10

-4

mbar

10

-2

mbar

1000 mbar

5×10

-9

mbar

Cald cathode

Pirani

•

The Pirani measuring circuit is always on

•

The cold cathode measuring circuit is controlled by the Pirani circuit and is

activated only at pressures <1×10

-2

mbar

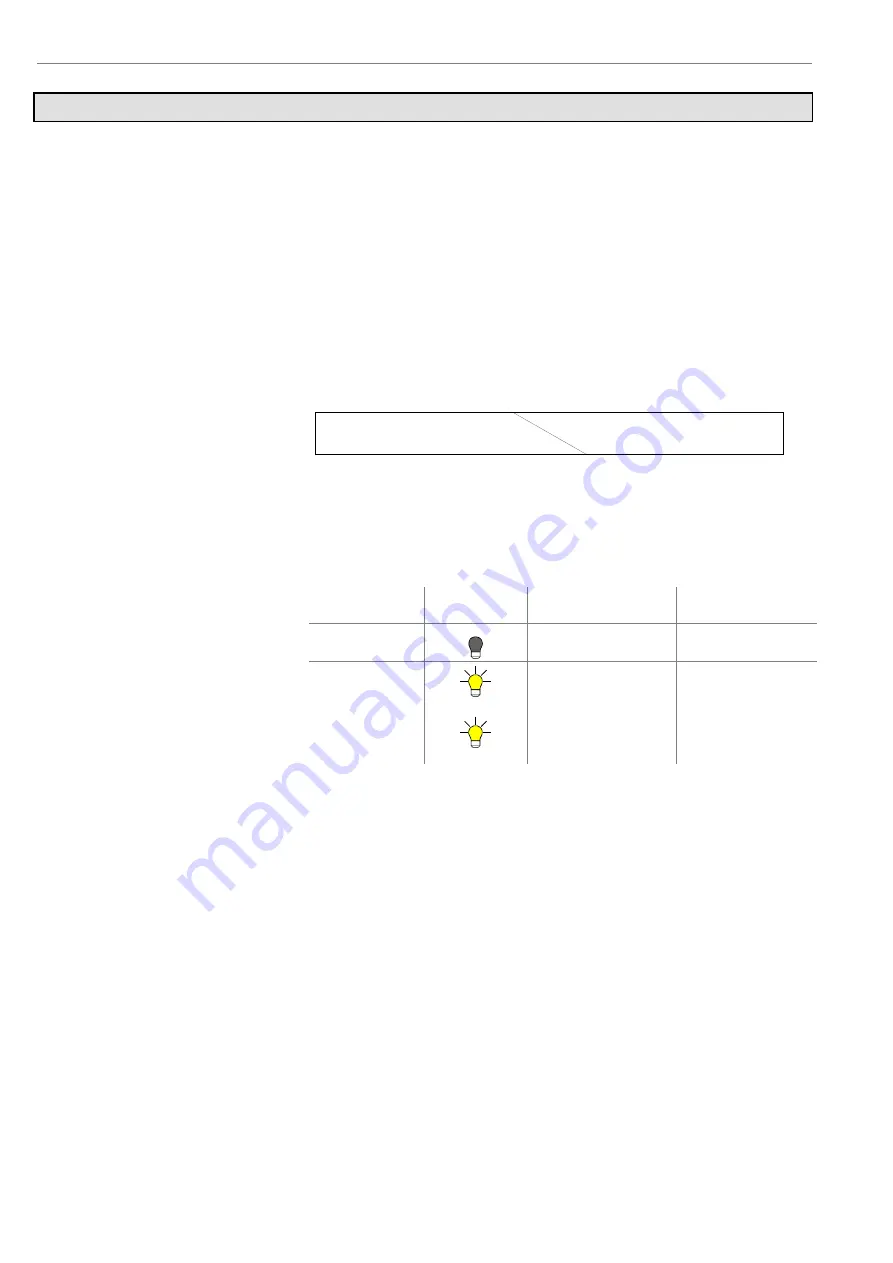

The identification output (pin 6) indicates the current status of the gauge:

Pressure

Lamp on the

gauge

Operating mode

Pin 6

p > 1

×

10

-2

mbar

Pirani-only mode

Low = 0 V

p < 1

×

10

-2

mbar

Cold cathode not

ignited

Pirani-only mode

Low = 0 V

p < 1

×

10

-2

mbar

Cold cathode ignited

Combined Pirani / cold

cathode mode

High = 15 … 30 VDC

As long as the cold cathode measuring circuit has not ignited, the measuring value

of the Pirani is output as measuring signal (if p < 5

×

10

-4

mbar, "Pirani underrange"

is displayed).

The measuring signal depends on the type of gas being measured. The curves are

accurate for dry air, O

2

, CO and N

2

. They can be mathematically converted for

other gases (

→

Appendix B).

If you are using an VARIAN controller, you can enter a calibration factor to correct

the pressure reading (

→

of that controller).

When cold cathode measuring systems are activated, an ignition delay occurs. The

delay time increases at low pressures and is typically:

10

-5

mbar

≈

1 second

10

-7

mbar

≈

20 seconds

5×10

-9

mbar

≈

2 minutes

4.1 Measurement Principle,

Measuring Behavior

Gas type dependence

Ignition delay