DOC: 03-925612-00

DESC:

PAGE:

REV

9 of 11

Assembly Procedure Station #3

1

PREPARED BY: Sax Makthepharack REVISED BY:

CONTROL: INDUSTRIAL ENGINEERING

REV. DATE:

SHOWN

-

06 - 08 - 98

Michael Slaughter

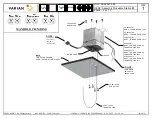

PNEUMATICS SIDE MANIFOLD

03-917142-00

VITON FERRULE

12-901150-00

SCREW

03-917141-00

CONDYNE PLATE

REF. ONLY

REFERENCE ONLY

PNEU. MANIFOLD

REFERENCE LINE FROM

MODULE TO DETECTOR BLUE (26”)

MAKE UP LINE FROM

MODULE TO DETECTOR BLUE (26”)

REFERENCE MODULE, BLUE (16”)

MAKEUP LINE TO MODULE, BLUE (16”)

MODULE PNEUMATICS CONNECTIONS

NOTES:

1. DRESS PLUMBING IN PNEUMATICS

COMPARTMENT USING CABLE TIE. INSPECT

TO ENSURE PNEUMATICS PANEL SWINGS FREELY.