Admissible temperatures

Operation °C

+5 … +60

Vacuum connection

°C

80

Filament °C

110

Storage

°C

–20 … +65

Relative humidity

%

≤

80 at temperatures up to

≤

+31 °C, decreasing to 50

at +40 °C

Use

indoors only, altitude up to

2000 m NN

Mounting orientation

any

Degree of protection

IP40

Dimensions mm

20.9

50

65

32.8

70.3

15

Weight

DN 16 ISO-KF

DN 16 CF-R

g

g

80

100

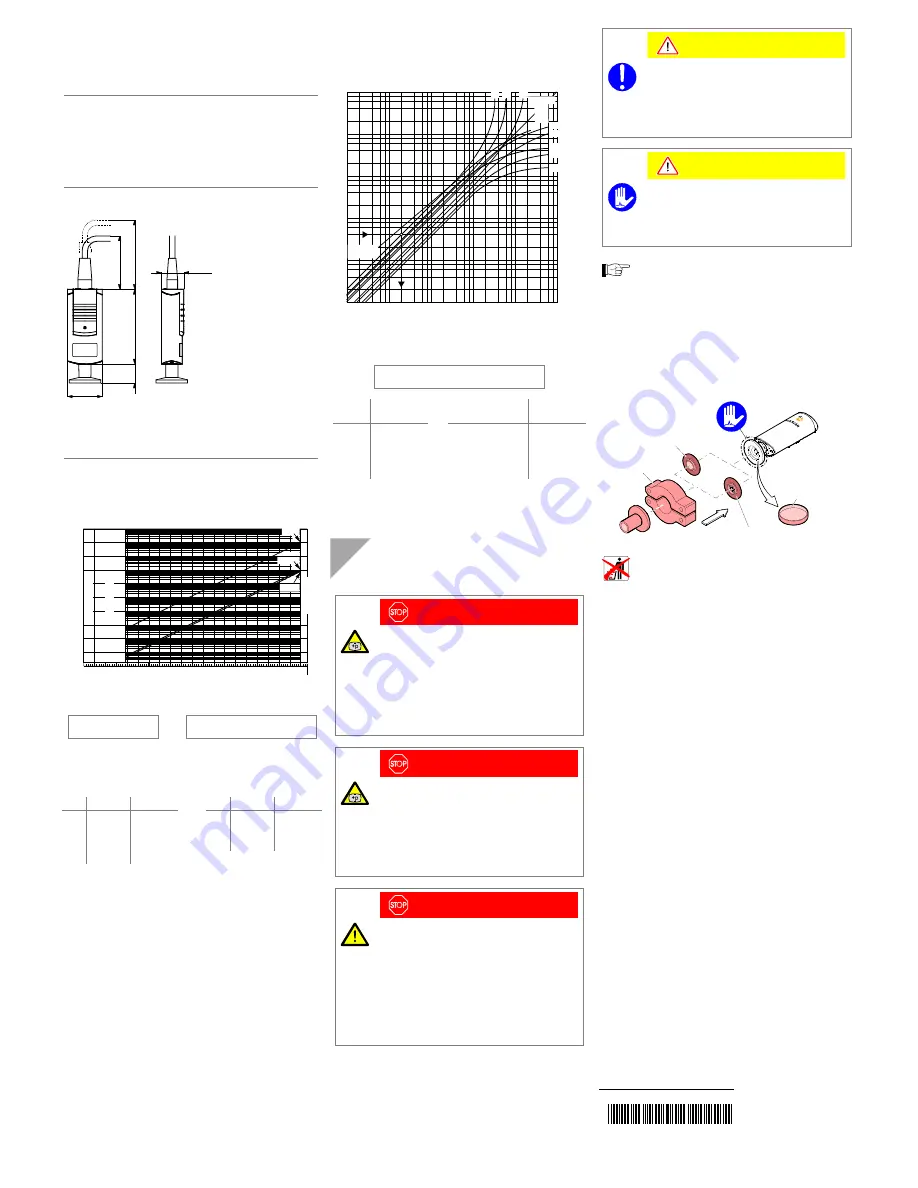

Measurement Signal vs. Pressure

1E+6

1E+4

1E+3

1E+2

1E+1

1E+0

1E–1

1E–2

1E–3

1E–4

0.0 0.5 1.0 1.5

2.5

3.5

4.5

5.5

6.5

7.5

8.5

9.5

10.3

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

mbar

Pa

1E+5

Torr

Under

ra

ng

e

S

ens

o

r er

ror

Pressure p [mbar]

Measurement signal U[V]

Over

ran

ge

p = 10

((U-c)/1.286)

⇔

U = c + 1.286 × log

10

p

valid in the range 5×10

-4

mbar <p< 1000 mbar

3.75×10

-4

Torr <p< 750 Torr

5×10

-2

Pa <p< 1×10

5

Pa

U p

c

U p

c

[V] [mbar] 6.143

[V] [micron] 2.448

[V] [µbar] 2.287

[V] [Pa] 3.572

[V] [Torr] 6.304

[V] [kPa] 7.429

[V] [mTorr] 2.448

where p pressure

U measurement signal

c constant (depending on pressure unit)

Gas Type Dependence

Pressure reading (gauge adjusted for air)

10

2

8

6

4

2

10

1

8

6

4

2

10

0

8

6

4

2

10

–1

8

6

4

2

10

–2

8

6

4

2

10

–3

10

–3

2

4

6

10

–2

2

4

6

10

–1

2

4

6

10

0

2

4

6

10

1

2

4

6

10

2

H

2

He

Ne

Xe

Kr

Ar

CO

2

Freon 12

Air

O

2

CO

N

2

p (mbar)

p

eff

(mbar)

Water vapor

Calibration factors for the pressure range below 1 mbar

p

eff

= C × pressure reading

Gas

type

Calibration

factor C

Gas

type Calibration

factor C

He

Ne

Ar

Kr

Xe

0.8

1.4

1.7

2.4

3.0

H

2

air, O

2

, CO, N

2

CO

2

water vapor

freon 12

0.5

1.0

0.9

0.5

0.7

Installation

Vacuum Connection

DANGER

DANGER: overpressure in the vacuum system

>1 bar

Injury caused by released parts and harm

caused by escaping process gases can result if

clamps are opened while the vacuum system is

pressurized.

Do not open any clamps while the vacuum sys-

tem is pressurized. Use the type of clamps which

are suited to overpressure.

DANGER

DANGER: overpressure in the vacuum system

>2.5 bar

KF connections with elastomer seals (e.g.

O-rings) cannot withstand such pressures. Pro-

cess media can thus leak and possibly damage

your health.

Use O-rings provided with an outer centering

ring.

DANGER

DANGER: protective ground

Incorrectly grounded products can be extremely

hazardous in the event of a fault.

The gauge must be electrically connected to the

grounded vacuum chamber. This connection

must conform to the requirements of a protective

connection according to EN 61010:

•

CF connections fulfill this requirement.

•

For gauges with a KF connection, use a con-

ductive metallic clamping ring.

Caution

Caution: vacuum component

Dirt and damages impair the function of the vac-

uum component.

When handling vacuum components, take ap-

propriate measures to ensure cleanliness and

prevent damages.

Caution

Caution: dirt sensitive area

Touching the product or parts thereof with bare

hands increases the desorption rate.

Always wear clean, lint-free gloves and use

clean tools when working in this area.

The gauge may be mounted in any orientation. To

keep condensates and particles from getting into the

measuring chamber preferably choose a horizontal

to upright position and possibly use a seal with a

centering ring and filter. If adjustment should be pos-

sible after the gauge has been installed, be sure to

install it so that the button can be accessed with a

pin (

→

"Adjusting the Gauge").

Remove the protective lid and install the product to the vac-

uum system.

Clamp

Seal with centering ring

Seal with centering

ring and filter

Protective lid

or

Keep the protective lid.

t qna44e1

(2010-05)