Power Connection

Make sure the vacuum connection is properly made

(

→

"Vacuum Connection").

n

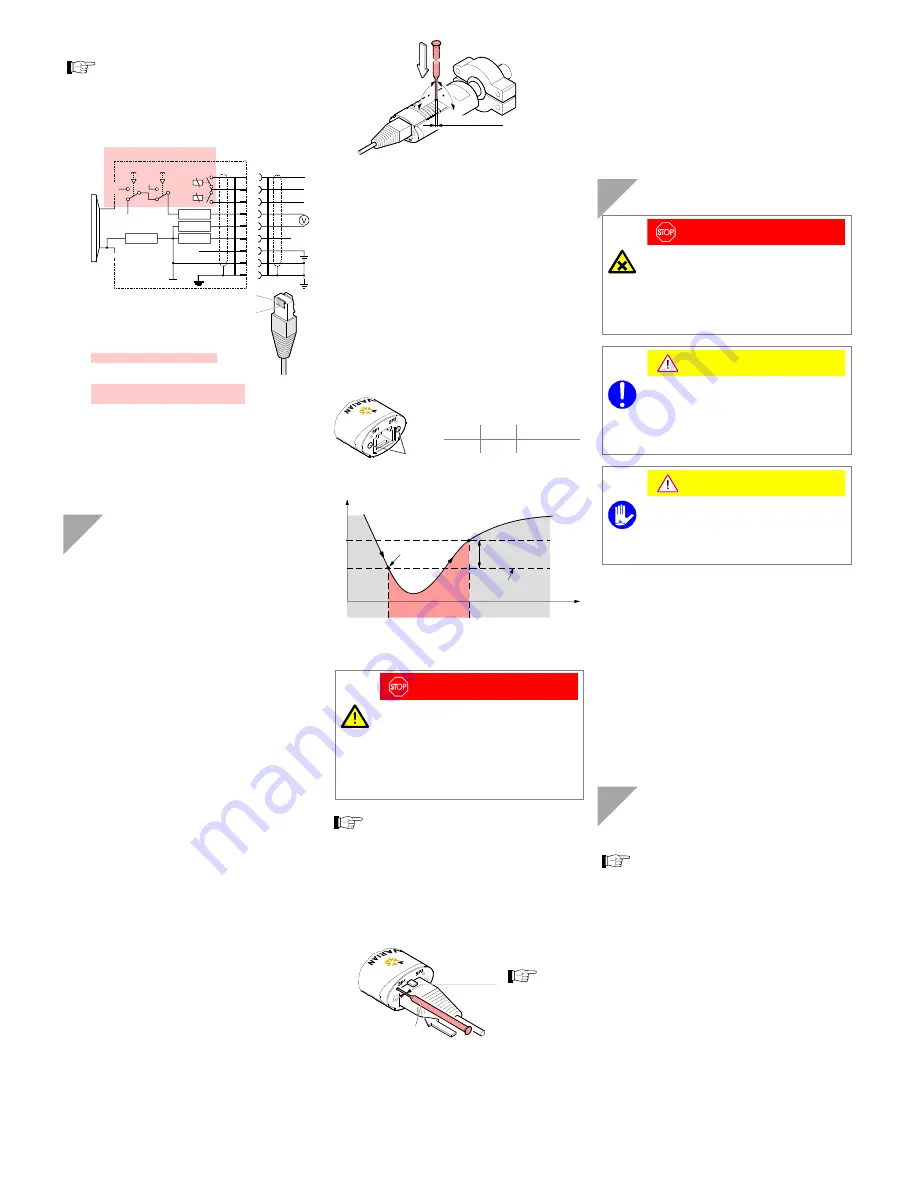

If no sensor cable is available, make one according to

the following diagram.

7

3

5

4

1

2

8

6

27k

Ω

+

4.7

Ω

4.7

Ω

1M

Ω

+

–

+

–

Ident

SP2

SP1

<SP1> <SP2>

SP2

SP1

Measurement

signal

Gauge with switching functions

Electrical connection

Pin 1

Supply

Pin 2

Supply common, GND

Pin 3

Measurement signal

or

thresholds

SP1/2

Pin 4

Gauge identification

Pin 5

Signal common

Pin 6, 8 Relay SP2, closing contact

Pin 7, 8 Relay SP1, closing contact

8-pole

FCC-68

connector

1

8

o

Connect the sensor cable to the gauge and the control-

ler.

Operation

When the supply voltage is applied, the measurement signal

is available between pins 3 and 5 (relationship between

measurement signal and pressure

→

"Technical Data").

Allow a stabilization period of at least 10 minutes. It is advis-

able to operate the gauge continuously, irrespective of the

pressure.

Gas Type Dependence

The measurement value is gas dependent. The pressure

reading applies to dry air, O

2

, CO and N

2

. For other gases, it

has to be corrected (

→

"Technical Data").

If the gauge is operated with an VARIAN controller, a cali-

bration factor for correction of the actual reading can be ap-

plied (

→

of the corresponding controller).

Adjusting the Gauge

The gauge is factory calibrated. Due to long time operation or

contamination, a zero drift could occur. Periodically check the

zero and adjust it if necessary.

For adjusting the zero, operate the gauge under the same

ambient conditions and in the same mounting orientation as

normally.

The gauge is adjusted to default values. However, it can also

be adjusted to other pressure values, if the exact pressure

value is known (reference measurement).

n

If you are using a seal with centering ring and filter,

check that they are clean or replace them if necessary

(

→

"Deinstallation").

o

Activate the gauge and operate it at atmospheric pres-

sure for at least 10 minutes.

p

Press the button with a pin (max. ø1.1 mm) and the

ATM adjustment is carried out: The gauge is adjusted

to 1000 mbar (10 VDC) by default. By pressing the

button >5 s the pressure value is increased towards

1200 mbar (or, by pressing it again, decreased towards

500 mbar) until the button is released or the limit is

reached.

max. ø1,1 mm

ATM

HV

q

Evacuate to p << 10

-4

mbar (recommended) or to a

pressure in the range of 10

-4

… 10

-2

mbar and wait at

least 2 minutes.

r

Press the button with a pin and the HV adjustment is

carried out: The gauge is adjusted to 1.2×10

-4

mbar

(1.1 VDC) by default. By pressing the button >5 s the

pressure value is increased toward 1×10

-2

mbar until

the button is released or the limit is reached.

Switching Functions

The setpoints are adjustable within a pressure range of

2×10

-3

… 500 mbar (voltage range of 2.67 … 9.61 VDC).

Each switching function provides a floating relay contact

(

→

"Electrical Connection").

LEDs

The status of the switching func-

tion is indicated by a LED.

Status

LED Relay

off off

deenergized

Measurement signal

(Pressure p)

Time t

Me

asu

reme

nt value

Off

On

Hysteresis (10%

of threshold value)

Off

Threshold value

Setpoint

Adjusting the Setpoints

DANGER

DANGER: malfunction

If processes are controlled via the signal output,

keep in mind that by pressing a button <SP> the

measururement signal is suppressed and that

the corresponding threshold value is output in-

stead. This can cause malfunctions.

Press a button <SP> only if you are sure that no

damages can arise from a malfunction.

The status of the relay and LED is not affected by

pressing the button.

n

Press the button <SP1> with a pin (max. ø1.1 mm):

The gauge changes to the switching function mode and

outputs the current lower threshold value at the

measurement value output for about 5 s. When the

button is kept depressed for more than 5 s, the

threshold setting is modified until the button is released

or until the limit of the setting range is reached.

max. ø1,1 mm

Keep the button

depressed

The upper thresh-

old is 10% above

the lower one

(hysteresis).

o

When the button is pressed again within 5 s the thresh-

old setting is adjusted in the reverse direction.

p

Release the button. The gauge resumes operation after

5 s and the connected controller displays the current

measurement value.

The adjustment procedure for <SP2> is the same as de-

scribed for <SP1>.

Deinstallation

DANGER

DANGER: contaminated parts

Contaminated parts can be detrimental to health

and environment.

Before beginning to work, find out whether any

parts are contaminated. Adhere to the relevant

regulations and take the necessary precautions

when handling contaminated parts.

Caution

Caution: vacuum component

Dirt and damages impair the function of the vac-

uum component.

When handling vacuum components, take ap-

propriate measures to ensure cleanliness and

prevent damages.

Caution

Caution: dirt sensitive area

Touching the product or parts thereof with bare

hands increases the desorption rate.

Always wear clean, lint-free gloves and use

clean tools when working in this area.

n

Vent the vacuum system.

o

Put the gauge out of operation.

p

Unplug the sensor cable.

q

Remove the gauge from the vacuum system and install

the protective lid.

Maintenance, Repair

In case of severe contamination or a malfunction, the sensor

can be replaced.

Gauge failures due to contamination or wear and

tear, as well as expendable parts (filament), are not

covered by the warranty.

VARIAN assumes no liability and the warranty becomes null

and void if any repair work is carried out by the end-user or

third parties.