2000 MS Hardware Maintenance

18

Functional Description

The diffusion pump may be restarted at any time during the shutdown procedure

providing no fault condition exists. The controller will restore power to the

diffusion pump if it receives a restart command during the first fifteen minutes of

the shut down procedure. The diffusion pump will reach operational temperature,

and the controller will issue a “DIFFUSION PUMP NORMAL” signal to the

SAP/Wave board after fifteen minutes. A full thirty-minute start up will be initiated

if the controller receives a restart command during the second fifteen minutes of

the shut down procedure.

Thermocouple Gauge

A thermocouple gauge is a simple, rugged, vacuum gauge that is used to

measure vacuum pressures in the 2 Torr (267 Pa) to 1 x 10

-3

Torr (1.3 x 10

-1

Pa)

range. The gauge’s main purpose is to enable the diffusion pump controller to

detect gross leaks and foreline pump failure.

The thermocouple gauge is active whenever the diffusion pump controller is

active. It is monitored during start up to ensure the vacuum system has been

pumped down to the diffusion pump’s required operational pressure. Once the

diffusion pump is operational, the thermocouple gauge is monitored to ensure the

operational pressure is maintained.

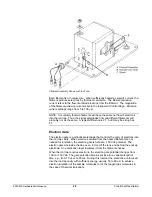

The Pneumatics Manifold

The pneumatics manifold is an aluminum block mounted to the front of the

vacuum manifold. It is equipped with two solenoid and needle valves for the cal

gas and CI, the glass cal gas vial, and vent valve.

The vent valve is a manually operated valve that connects to atmosphere via the

pneumatics manifold. You open and close the vent valve via a toggle arm, which

is accessible from the front of the instrument.

The calibration-gas-valve assembly consists of a metering needle valve, an

ON/OFF solenoid-operated valve, and a glass vial containing the calibration

liquid. The assembly sits directly behind the instrument’s door. The needle valve

controls calibration gas flow into the vacuum manifold through the solenoid valve.

The calibration compound is perfluorotributylamine (PFTBA) or C

12

F

27

N, also

known as fluorocarbon-43 (FC-43). A small glass vial attached to the valve

assembly holds the compound. You set the flow of calibration gas into the

manifold manually via a needle valve. The data system controls the opening and

closing of the solenoid-operated valve.

Two solenoid valves control the flow of CI reagent gas into the manifold. First,

the shutoff valve near the rear panel opens to permit reagent gas flow into the

instrument through a fitting. When this valve is open, the foreline pump removes

a portion of the CI gas to prevent CI gas surges (pressure pulses) in the ion trap.

The gas then flows through the shutoff valve through metering and solenoid-

operated valves before entering the vacuum manifold. With the CI gas solenoid

open, the CI needle valve determines the split ratio of the reagent flow between

the manifold and foreline pump.

You turn the CI reagent gas valve on and off via the data system from the

Instrument Control Page or Acquisition, you adjust the flow rate of the reagent

gas into the manifold by means of a metering valve.