ODHGIES CRHSEWS

43 87-900-940-01 (

F

)

EmprovsqioÇ pivnakaÇ tou Ruqmisthv

969-9437

kai

969-9537

DIADIKASIES CRHSHS

vAnamma tou Ruqmisthv

Gia na anavyei o ruqmisthvÇ einai arketov na bavlete to

kalwvdio trofodosivaÇ sthn privza tou diktuvou.

Ekkivnhsh thÇ AntlivaÇ

Gia na teqeiv se kivnhsh h antliva qa prevpei na

pathvsete to koumpiv

START

tou emprovsqiou pivnaka

.

Stavsh thÇ AntlivaÇ

Gia na stamathvsei h antliva arkeiv na pathvsete to

koumpiv

STOP

tou emprovsqiou pivnaka

.

SUNTHRHSH

Oi ruqmistevÇ thÇ seiravÇ

Turbo-V 301

den apaitouvn kamiva

sunthvrhsh. Opoiadhvpote epevmbash qa prevpei na

pragmatopoihqeiv apov exousiodothmevno proswpikov.

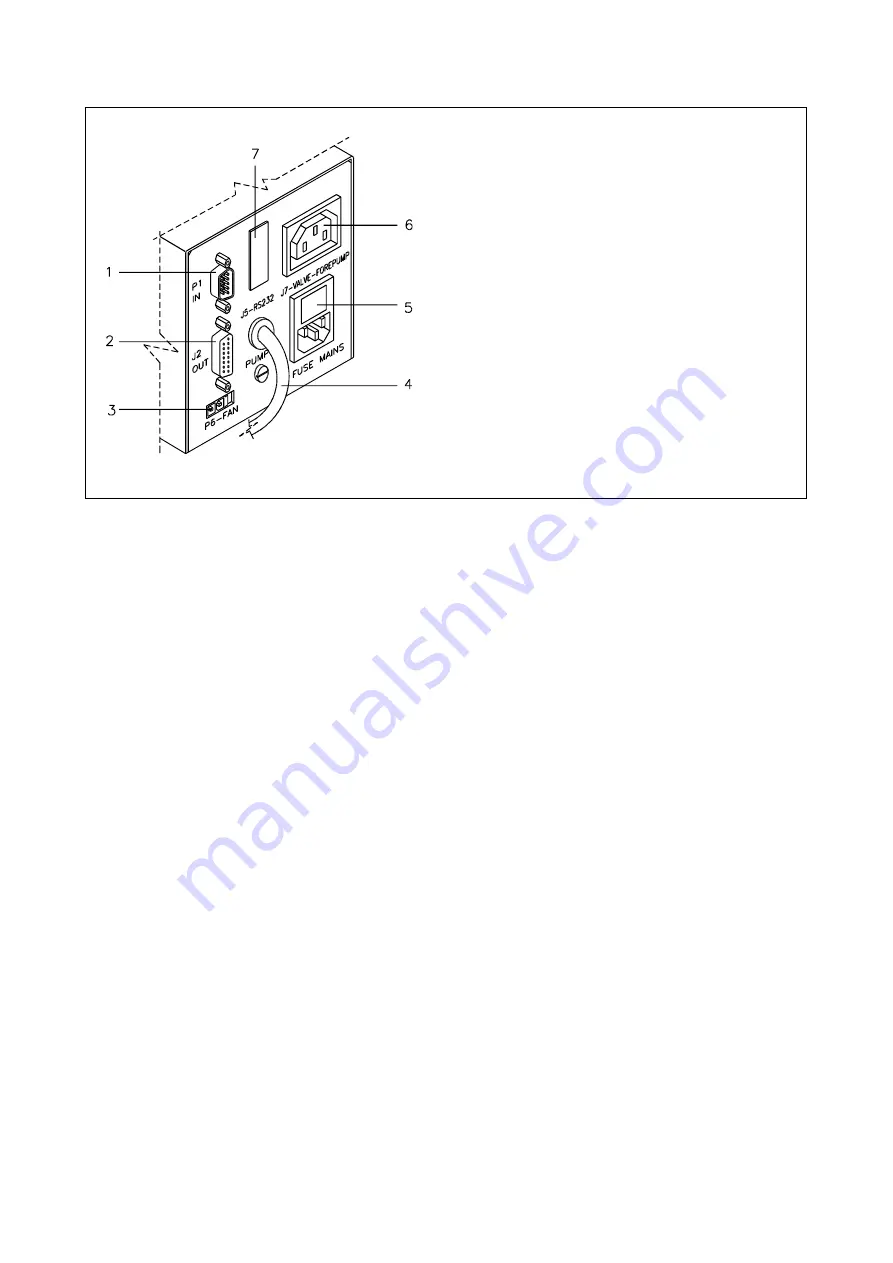

1.

Buvsma eisovdou twvn logikwvn shmavtwn (to buvsma zeugarwvmatoÇ

promhqeuvetai me to eidikov gefuravki kleisivmatoÇ).

2.

Buvsma exovdou twn logikwvn shmavtwn kai epalhvqeushÇ tou

reuvmatoÇ thÇ antlivaÇ.

3.

Buvsma exovdou iscuvoÇ

(24 Vac

gia ton anemisthvra yuvxhÇ

antlivaÇ).

4.

Kalwvdio antlivaÇ.

5.

Enovthta eisovdou thÇ trofodovthshÇ gia to Ruqmisthv.

Perilambavnei thn asfavleia prostasivaÇ, thn allaghv tavshÇ,

thn privza trofodovthshÇ iscuvoÇ kai to fivltro

EMC

.

6.

Privza exovdou iscuvoÇ

(120 Vac)

gia thn trofodovthsh twn

proairetikwvn exarthmavtwn (

vent device

, relev energopoivhshÇ thÇ

prwtarcikhvÇ antlivaÇ klp.).

7.

ProblepovmenoÇ cwvroÇ gia to buvsma thÇ povrtaÇ seiriakhvÇ

epikoinwnivaÇ

RS 232

(promhqeuvontai proairetikav).

Summary of Contents for Turbo-V 301

Page 2: ...Turbo V 301 Rack Controller...

Page 3: ......