SECTION II - INSTALLATION

87-900-865-01 (

B

)

5

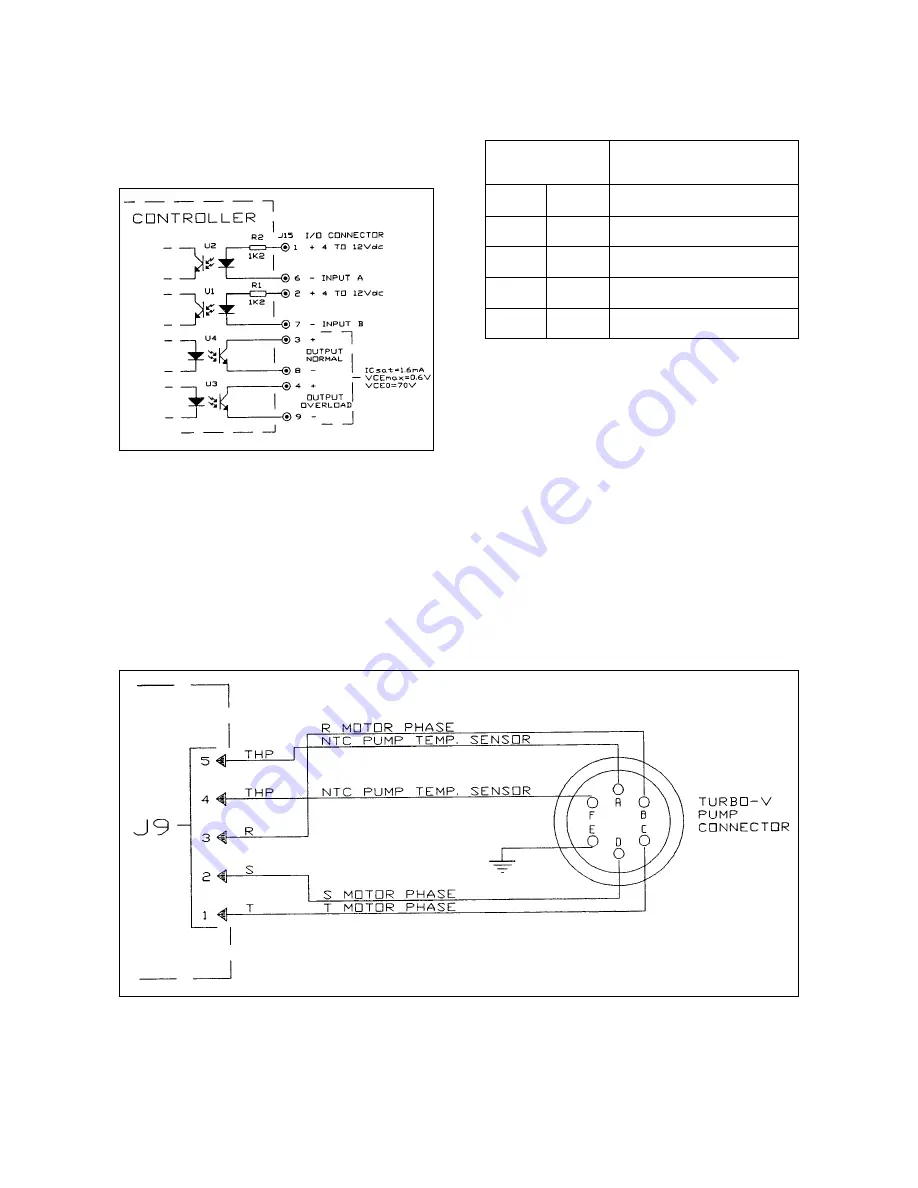

2-4 Input/Output interconnections

All the input/output signals to the controller must be

connected at J15 mating connector (see Fig. 2-2).

Figure 2-2 – Input/Output connector

Pin 1-6

Input A optically isolated from the internal

circuit.

In conjunction with the Input B determines the controller

mode of operation according to the following truth table.

Pin 2-7

Input B optically isolated from the internal

circuit.

In conjunction with the Input A determines the controller

mode of operation according to the following truth table.

INPUT SIGNAL

LOGIC LEVEL

CONTROL UNIT

CONDITION

A

B

LOW

LOW

LOW FREQUENCY

LOW

HIGH

HIGH FREQUENCY

HIGH

LOW

HIGH FREQUENCY

HIGH

HIGH

LOW FREQUENCY

Pin 3-8

Output Normal optically isolated from the

internal circuit.

Pin 4-9

Output Overload optically isolated from the

internal circuit.

2-5 Turbo-V pump connection

A 55 cm long cable is provided to connect the controller

to the pump.

Figure 2-3 shows the pump output connector

configuration where pins:

Pins A-F = pump temperature sensor

Pins B-C-D = 54 Vac 3-phase output to pump motor

stator

Pin E = ground.

Figure 2-3 – Turbo-V pump connector

Summary of Contents for Turbo-V60

Page 2: ...Turbo V 60 Leak Detector PCB Controller...

Page 3: ......

Page 4: ......

Page 15: ...SECTION IV MAINTENANCE 87 900 865 01 B 10 Figure 4 1...