WARNING

Diffusion pump heaters operate at voltages high enough to kill through

electrical shock. During installation, check the drawings and be sure to

attach all hazard warnings and cautions. Always break the primary cir-

cuit of the power supply when direct access to the heater or wiring is

required. Read the safety section in the front of this manual.

Installation

1-3

1-2-3

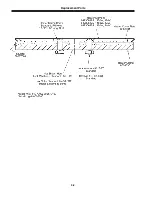

Vacuum System Connections

a

The diffusion pump must be installed with the body vertical and plumb. Check to ensure that

the pump inlet mating flange on the system is horizontal within ± one degree. The boiler plate

must be horizontal to prevent uneven fluid level. Failure to meet this requirement could result

in overheating of the diffusion pump boiler plate.

b

Prepare the inlet and foreline O-rings by wiping them with a clean, lint-free cloth. A small

amount of diffusion pump oil may be used to clean the O-rings.

c

Install the O-rings in the O-ring grooves. Be careful not to damage or scratch the sealing surface.

d

Check the fill plug for tightness. Apply light to medium torque, enough to compress the O-rings.

e

Using the appropriate lifting apparatus, align the bolt holes of the inlet flange with the bolt

holes of the mating flange. Using the appropriate mounting hardware, tighten the bolts evenly

until the O-ring is compressed and the flanges make light, metal-to-metal contact.

f

To ensure the integrity of the vacuum connections, they should be checked for leaks using a

helium mass spectrometer leak detector before operating the vacuum system.

1-2-4

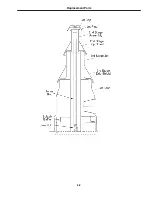

Cooling Water Connections

a

The inlet water fitting (near the inlet flange at the top of the pump) should be connected to a

continuously running water supply at 0.25 gpm and at a temperature of 60 to 80oF.

b

The exit water temperature should not exceed 120°F.

c

The outlet or discharge (nearest the foreline) should be connected to an open drain.

d

If the diffusion pump is being cooled by a recirculating water system, the system must be

capable of adequate cooling and heat exchange to ensure a continuous inlet temperature of

60 to 80°F. The recirculating system must also be capable of maintaining an adequate flow

rate to ensure that exit water temperature does not exceed 120°F. The minimum rating of this

system should be 85 percent of the maximum power rating of the diffusion pump.

e

The quick cool coil feed line, located at the boiler plate, shoud be controlled by a separate

three-way valve (open, closed, and vent to atmosphere).

f

The quick cool drain must be connected to an open drain which is below the inlet connection

of the quick cool coil. This will ensure that the quick cool coil is completely drained when the

cooling water supply is turned off and the pump is vented to atmosphere.

NOTE

________

In the following step, discharge connections must be installed in accor-

dance with all Federal, State, and local laws and regulations.

Summary of Contents for VHS-6

Page 27: ...Replacement Parts 5 2 ...

Page 28: ...Replacement Parts 5 3 ...