3-1

c

After isolating the backing pump, the diffusion pump may be vented to atmosphere.

d

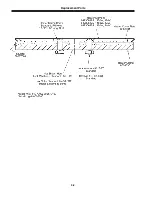

If faster cooling is desired, the pump can be cooled using the quick cool coil at the bottom of

the diffusion pump. Follow the instructions in para. 1-3-3 for proper setup of the quick cool coil

line. The same procedure for shutdown can be followed.

SECTION III

MAINTENANCE AND SERVICE

3-1

GENERAL

Diffusion pumps generally require little attention when operated correctly. It is advisable to perform

some periodic inspections to ensure trouble-free operation. By performing simple preventive mainte-

nance, costly downtime can be avoided. A day-to-day log of pump and system performance will help

indicate the condition of the pump and the need for corrective action.

3-2

PERIODIC INSPECTION

The frequency of inspection will depend on the type of system, its operation, and use. The maximum

interval between inspections is established on the basis of experience. It is recommended that the

following items be regularly examined.

a

When the pump is cold, check the condition and level of the fluid. These can be inspected by

withdrawing a fluid sample through the drain and by visually checking the level of the fluid

through the sight glass. A slight discoloration of the fluid does not affect performance. Always

use new o-rings when replacing fill plugs or the sight glass.

b

Loss of fluid can be caused by the following:

1 Incorrect venting procedures and/or admittance of excessive air or other gas to a hot pump.

2 Inadequate water cooling.

3 Prolonged operation at inlet pressures above 10

-3

Torr (.133 Pa).

4 Failure to reinsert the foreline baffle in the pump assembly.

c

Check the total heater power input.

d

When the pump is cold and the power is off, check to ensure that the heater is bolted snugly

to the boiler plate. Also check all heater terminal connections at the heater and inside the

junction box and make certain that they are tight and in good condition.

e

Check to ensure that cooling water flow is adequate and unobstructed. In areas where the

mineral content of the water is high or where there is considerable sediment, it may be advis-

able to install water filters.

3-3

CLEANING

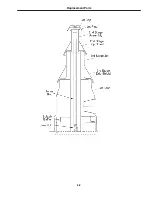

Complete cleaning of the pump may be periodically required because of the gradual deterioration of

some pump fluids. Removal of the pump from the system is then necessary.

a

Turn off the power and disconnect the power supply plug.

b

After the pump has cooled, turn off the cooling water and disconnect the cooling lines.

Summary of Contents for VHS-6

Page 27: ...Replacement Parts 5 2 ...

Page 28: ...Replacement Parts 5 3 ...