Troubleshooting

4-2

Table 4-1 Troubleshooting

Fault

Probable Cause

Corrective Action

Poor system pressure

Leaks in system, virtual or real

Locate and repair.

High process gas load

Measure gas load, eliminate cause.

System dirty

Clean system to reduce outgassing.

Poor ultimate pressure

Contaminated pump fluid

Examine, clean pump,replace fluid.

Low heat input

Check voltage. Check for continuity,

burned-out element, poor thermal

contact.

Inadequate cooling water flow

Check water pressure. Check tubing

for obstructions and backpressure.

Excessive or too cold cooling water

Check temperature. Adjust flow.

High forepressure

Check for leak in foreline, poor

mechanical pump performance,

breakdown of mechanical pump fluid.

Water in quick-cool coil

Check and remove water.

Low heat input

Check heaters.

Low oil level

Add oil.

Malfunctioning pump assembly.

Check and repair or replace.

Improperly located jets. Damaged

jet system.

Inlet pressure surges

Incorrect heater voltage

Check and correct voltage.

Fluid outgassing

Condition fluid by operating the

pump for a few hours.

Leak in system ahead of pump inlet

Check and correct.

High chamber

Forepressure too high

Check for leak in foreline, poor

contamination

mechanical pump performance,

breakdown of pump fluid, and

incorrect valve operation.

Prolonged operation at high through-

Review operating procedures.

put at pressure above 10

-3

Torr (.133 Pa)

Improper system operation and

Review operating procedures.

air release procedures

Pump will not start

Safety circuits and/or protective

Check utilities, flow switches,

devices prevent contactor from

interlocks. Check thermostat

staying closed

operation.

Slow pumpdown (Pro-

longed cycle after

checking gas goad

conditions)

Summary of Contents for VHS-6

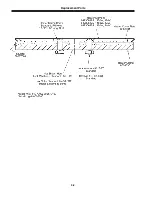

Page 27: ...Replacement Parts 5 2 ...

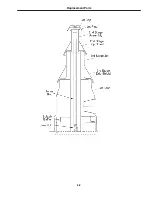

Page 28: ...Replacement Parts 5 3 ...