Page 15

CHAPTER 2 - INSTALLATION

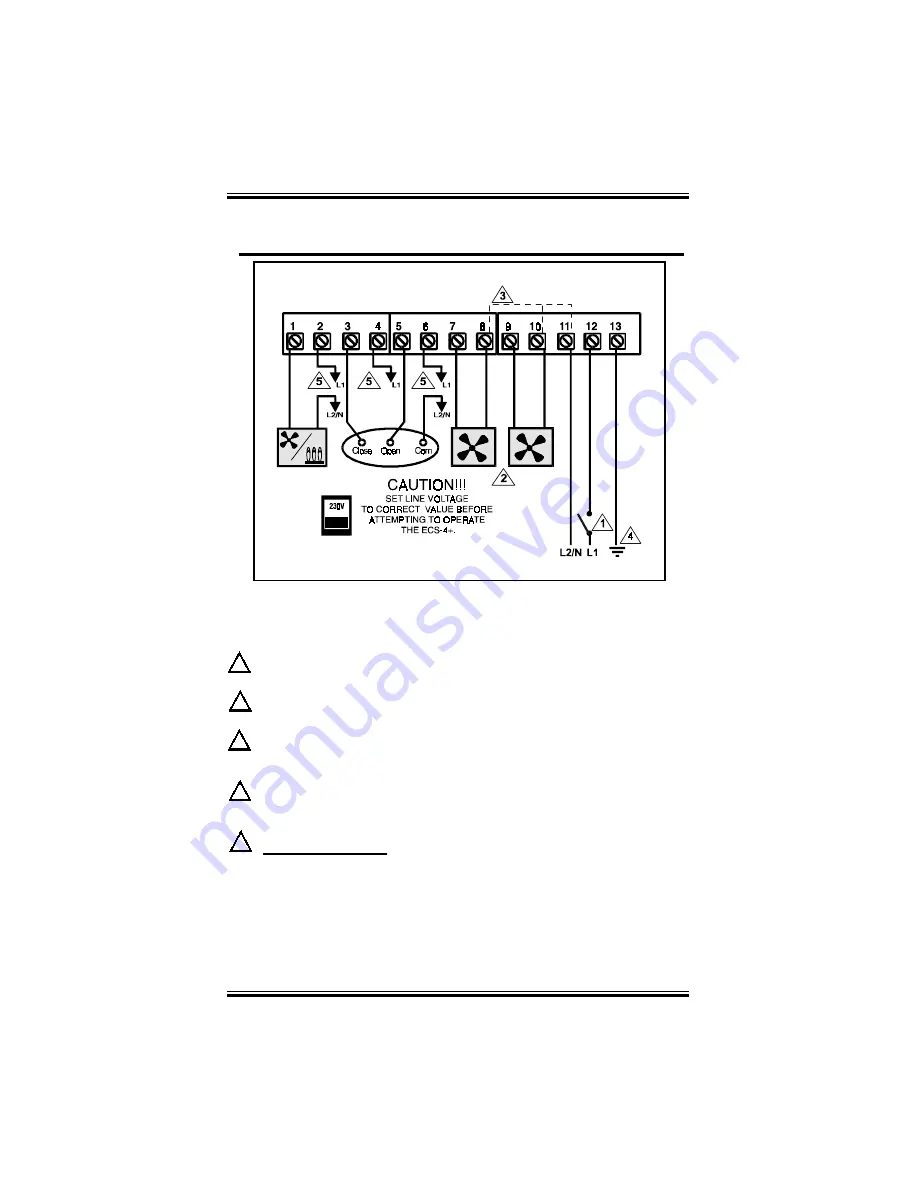

Figure 2

Two fans, one actuator and one heating unit

4

Notes for Figures 2 and 6

Power cut and protection devices in case of overload.

Only use fans that have thermal protection devices.

Terminals 8, 10, and 11 are internally connected.

Connect the ground wire to ground terminal 13.

IMPORTANT

Must be on a 15A separate circuit of

the ECS. Make sure to disconnect power of the source

and all loads before wiring.

1

2

4

3

5

www.monitrol.com