Formular-Nr.:51 Rev.-Nr.:10 01/18

- 3 -

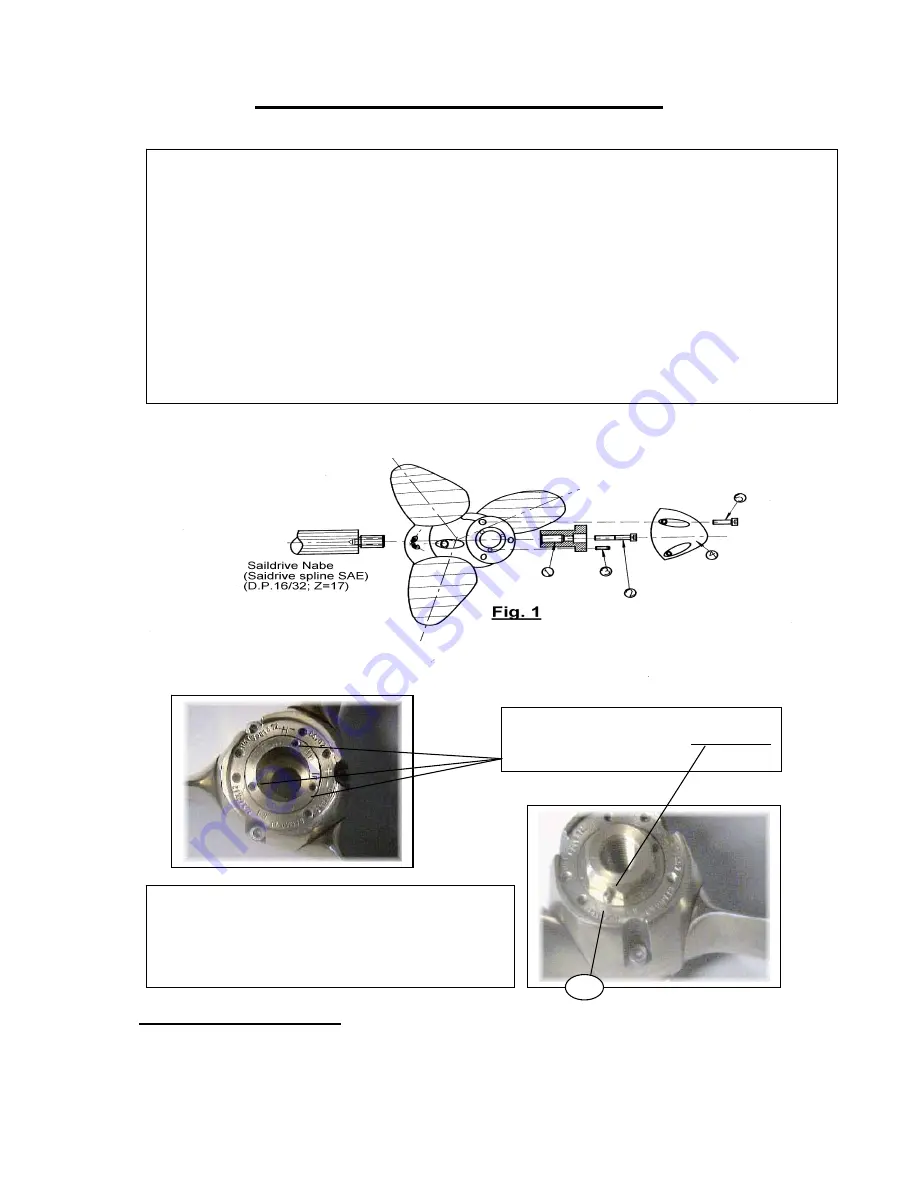

INSTALLATION on the SAILDRIVE

The VARIPROP is delivered assembled, greased and ready for installation.

ATTACHING THE ZINC-CONE:

First, insert all three zinc-cone screws

( 1 )

loosely, then tighten securely in succession. Use LOCTITE

low (pink) and observe the little washers. They prevent the grease from squeezing out of the hub

during operations. Be sure to clean the screws and screw-holes from any grease before applying the

loctite.

Only two

of the three lock-pin holes can

be used, depending on the final position

of the shaft-nut flange.

Carefully align the lock-pins

(3)

straight. They must go

in easily. If not, try first to tighten the propnut a little

further until they do. If impossible, back off the nut a

little. The lock-pins

should be hand tightened only.

If overtightened they may strip.

Before mounting the VARIPROP properly onto the saildrive spline, please check if the propeller hub gears

mate precisely with the saildrive spline grooves. Tolerances are very tight to avoid on-axis movement.

Some careful “wiggling” may be required to find the exact position where the hub slides unto the spline.

After removal ot the zinc cone (4) and the propeller nut (1) the propeller hub will slide completely unto the

spline. Tighten nut (1) strongly ( 60Nm / 45ft/lb; Yanmar SD 40/50 100Nm / 75ft/lb ) and use loctite low

(pink) .

Observe the recommended torque settings of the saildrive manufacturer.

After installation, check that there is only a little end clearance for the prop on the saildrive shaft. If it is too

high, fit one or more of the different spacer disc between the forward end of the prop and the saildrive to

reduce it. The spacer discs are delivered with the prop.

Secure the propeller nut (1) with the hexagonal socket cap screw ( 2 ( M8x45 DF-80 / M8x60 DF-107 /

15Nm / 10ft/lb) and two lock pins (3). Hand tighten only, and then mount the zinc cone ( see below ). Make

sure that the propeller is always protected from electrolytic corrosion by changing the zinc anode (2) latest

every year, less often in fresh water. After the VARIPROP has been fitted properly check that the blades

rotate freely from the forward stop to the reverse stop. The shock absorber function can be felt ! See

servicing page 10.

3