Formular-Nr.:51 Rev.-Nr.:10 01/18

- 6 -

PITCH ADJUSTMENT „RH“

GERNAL:

The pitch adjustment is very simple on the VARIPROP, and can be done in or out of the water in

a matter of few minutes, if there is enough space between propeller hub and strut to fit an Allen

key into the set screws (1) & (3) at Fig.3a. If not, the propeller must first be pulled. ( see removing

from the shaft )

Propeller in the drawing below (Fig.3a) is for a

right hand

rotation

RH.

Fig.3a

The following description refers to the view towards astern for a

right hand VARIPROP

.

A. Adjusting the forward pitch :

B. Adjusting the reverse pitch :

1. Remove the set screw (1/ 4mm allen key).

1.

Remove the set screw (3/ 4mm allen key).

Under water: only 3 turns loosen. Under water: only 3 turns loosen.

2. Turn the adjusting screw (2) which is marked as

2.

Turn the adjusting screw (4) which is marked as

“AH” or “V”

with the 5mm Allen-key as follows:

“AS” or “R”

with the 5mm Allen-key as follows:

2a.

Increasing of pitch approx. 3“ max.:

2a.

Increasing of pitch approx. 2“ max.:

- Turn the adjusting screw (2) clockwise. - Turn the adjusting screw (4) anti-clockwise.

( see “NOTE” and page 7) ( see “NOTE” note and page 7)

- Secure set screw (1) with LOCTITE low (pink). - Secure set screw (3) with LOCTITE low (pink).

- Lock set screw strongly. - Lock set screw strongly.

2b.

Reducing of pitch approx. 2“ max.:

2b.

Reducing of pitch approx. 3“ max.:

- Turn the adjusting screw (2) anti-clockwise. - Turn the adjusting screw (4) clockwise.

( see “NOTE” and page 7). ( see “NOTE” and page 7).

- Secure set screw (1) with LOCTITE low (pink). - Secure set screw (3) with LOCTITE low (pink).

- Lock set screw strongly. - Lock set screw strongly.

NOTE:

It is quite possible to set the pitch continuously variable and independently for forward and reverse.

The turning of the adjusting screws (2) & (4) by half a revolution (180°) changes the pitch approx. 1“. This will

change the engine revolution by approx. 200.

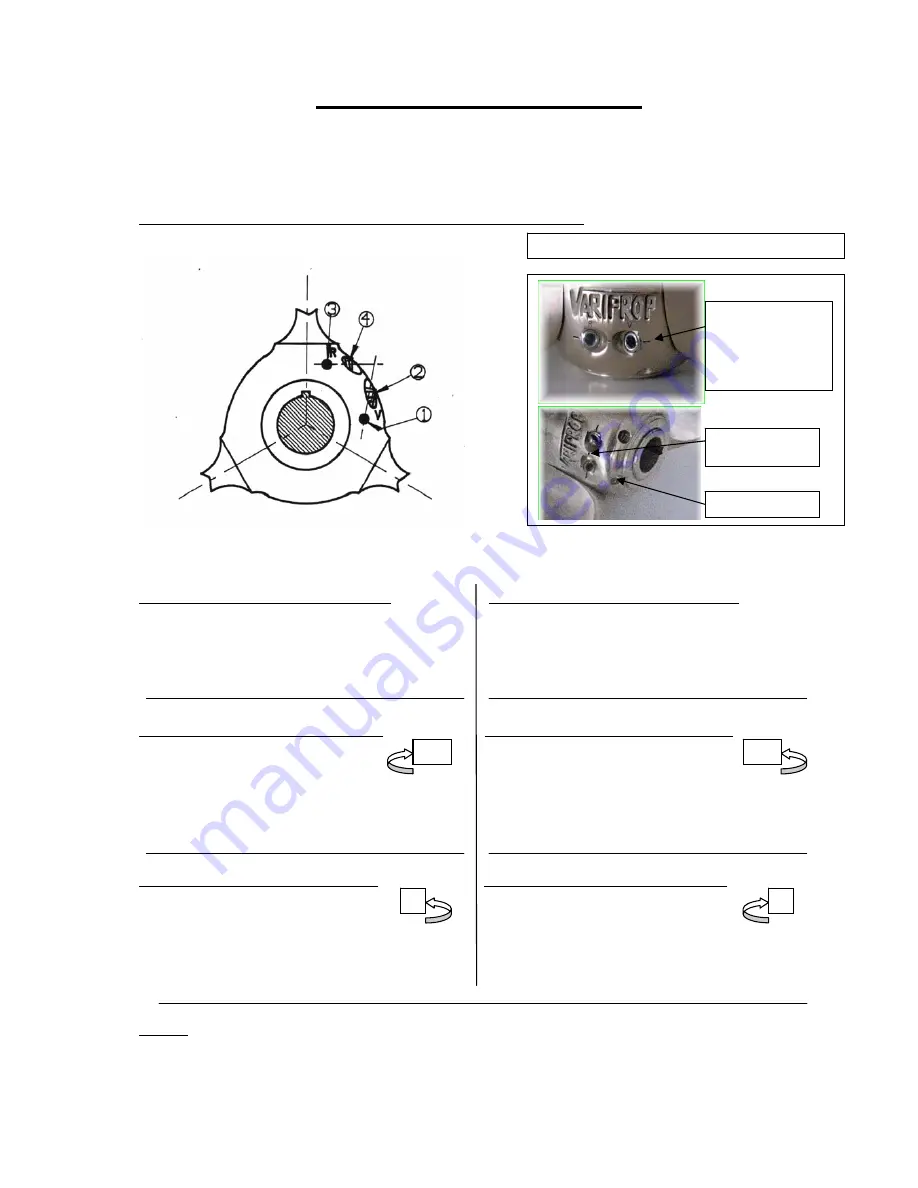

R= AS (Astern)

V= AH (Ahead)

.

+

+

-

-

adjustment markings

Markings to check

and determine

degree of pitch

adjustment

adjusting screws

(2&4)

set screws (1&3)