6-2

VariQuest

®

Cutout Maker 1800 User’s Guide

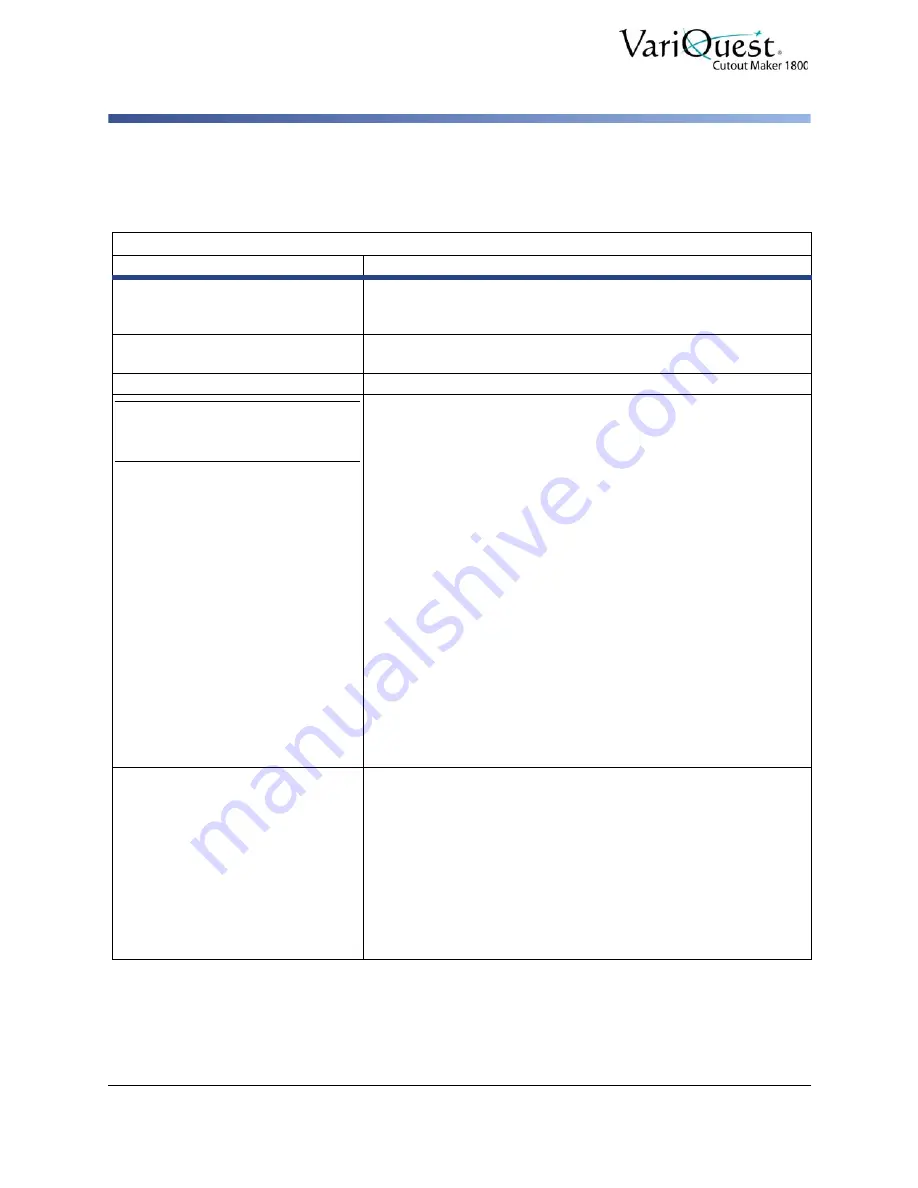

Troubleshooting

Tips

Troubleshooting

Troubleshooting

Diagnosis

Required Action

Cutout Maker does not work even

though the power switch has been

turned on.

1.

Verify that power cord has been plugged in properly.

2.

Verify that power switch is turned on.

LCD Display does not turn on.

1.

Verify that power cord has been plugged in properly.

2.

Verify that power switch is turned on.

Excessively loud noise.

1. Oil rails, see “Oil Gantry Rails” on page 5-10.

Note:

In each of the following cases,

follow the 5 steps shown in the

“Required Action” column.

•

Button presses don't seem to be

working.

•

The message box in the

VariQuest Software contains the

following message: “There was

an error communicating with the

cutter. You will need to recut

some or all of your job. Select

OK, then select the page or

pages to recut.”

•

The LCD Display on the Cutout

Maker doesn't change to a

screen saying “Ready” when the

user enters the initial Cutout

Maker screen in the VariQuest

Software.

1.

Verify that the Design Center touch computer or PC and the

Cutout Maker 1800

are turned on, and the power cord has

been plugged in properly.

2.

Verify that the USB cable is plugged into the

Design Center

touch computer or PC and the

Cutout Maker 1800

.

3.

Turn the device off/on.

4.

Close, then reopen the VariQuest Software. Turn the device

OFF, then ON to reestablish communication.

5.

Verify that the

Design Center

touch computer or PC is not

prompting to install the USB driver (Found New Hardware

Wizard). It is possible that the wizard is behind another window

on the Design Center touch computer or PC. Run the wizard to

install the USB driver, if needed.

6.

Verify that the print driver for the device is installed by opening

the “Printers and Faxes” control panel on the

Design Center

touch computer or PC, and verify that there is a printer named

“VariQuest". Run the printer setup from the CD, if needed.

Paper tears.

1.

Verify correct material was selected in VariQuest Software.

2.

Change cutting blade, see “Replacing the Cutting Blade” on

page 5-3.

3.

Replace the cutting mat if significant use is visible, see

“Replacing the Cutting Mat” on page 5-7.

4.

Adjust material settings, see VariQuest Software User's Guide.

5.

Clean mat with isopropyl alcohol.

6.

Rotate mat 180

o

.

7.

Replace mat.

8.

Clean the tip sensor. See

“Clean Tip Sensor”

on page 5-11.