12

Värmebaronen EP 26E and EP 42E

Operation and maintenance

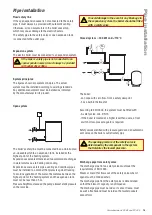

Before starting, check that the installation is in a fully

satisfactory condition.

Ask the installation engineer to demonstrate the control

and functions so that you know how the system works

and must be maintained.

Check that the boiler and heating system are filled with

water, vented and that the pressure is correct.

That all necessary valves are open.

That any safety valves are working.

That any external safety equipment is working as

intended.

That the circulation pump is working and the flow

direction is correct.

For configuration, see "Menu - Management".

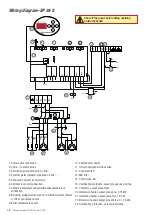

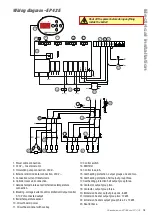

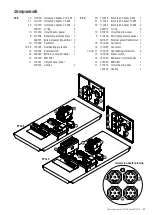

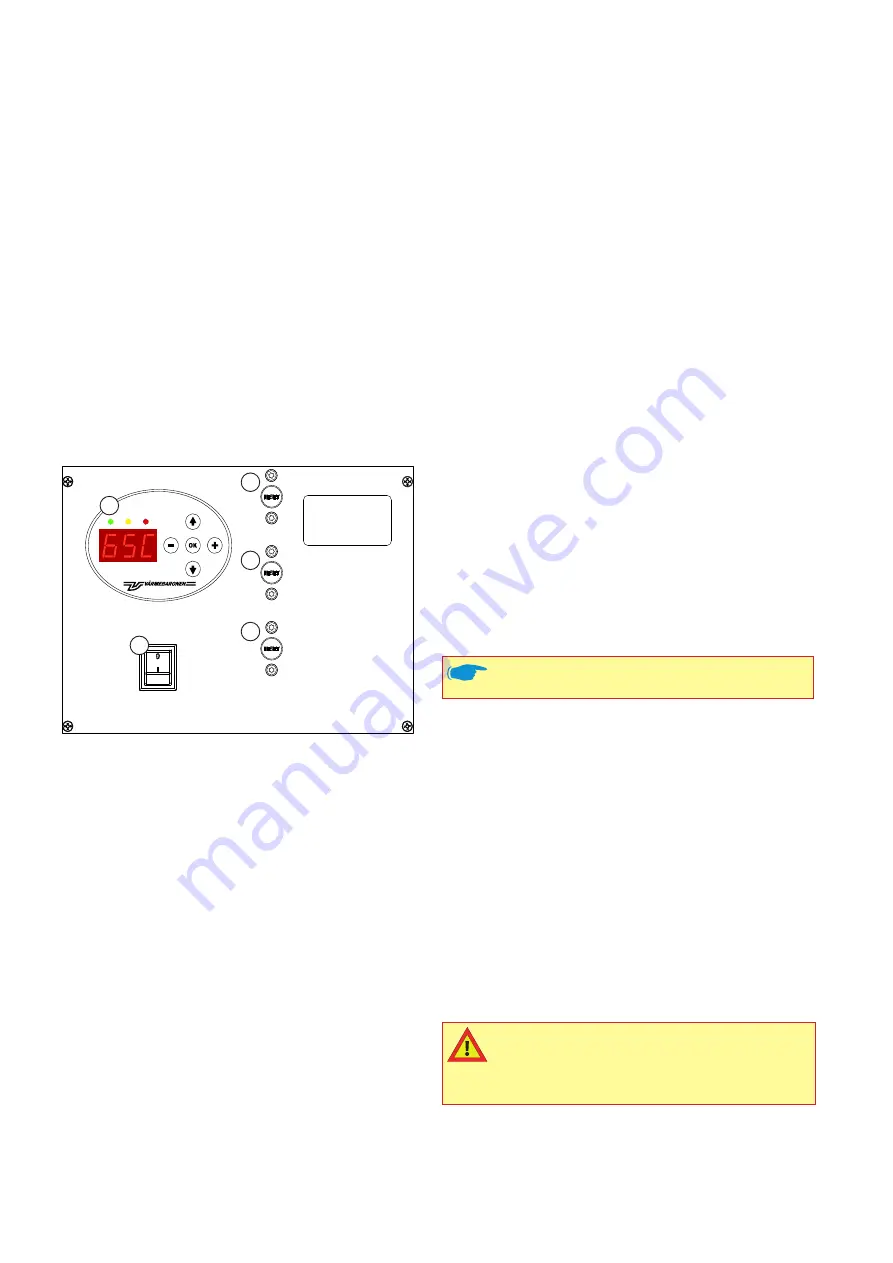

EP

11. Indicators, display and configuration buttons.

14. Control switch, two-pole

16-18. Reset overheating protection.

Start

1. Set the main/control switches to the on position,

the display lights up along with a green indicator.

2. Set the desired boiler temperature.

3. Because the boiler has been without power, only three

output stages are stepped in. The remaining output is

connected after one hour if necessary.

For testing and service, the delay can be temporarily

disconnected by changing row 2 of the installation/service

level to 1.

4. The boiler should now step in the number of output stages

needed until the temperature conforms to the set value.

The step in times can be reduced by changing row 1 in the

installation/service level to 1. Fast stepping is deactivated

automatically after 15 minutes.

Activation delay

According to the recommendations, a maximum of 50% of

the output should be connected immediately after a voltage

loss. The remaining output comes in after one hour. The delay

can be permanently disconnected by changing row 14 in the

advanced service level to 1.

Load guard

The load guard protects the main fuses against overload

by reducing the boiler's output. When the overload ceases,

the output is reconnected stage by stage.

See the menu item "Service Level" rows 3 and 4.

Safety valve

To maintain the safety function, safety valves in the heating

system must be operated regularly, about 4 times a year.

Venting - water pressure

Regularly check that the water pressure is correct. Air may

be left in the system for a while after installation, for which

reason it should be vented a few more times.

The pressure in a heating system varies with the

temperature. Do not add water unnecessarily!

Draining

If the heating system needs to be drained of water, the boiler

must first be switched off so that the immersion heaters are

not damaged.

Overheating protection

The boiler’s overheating protection is triggered if the

temperature exceeds approximately 100°C. The protection is

reset behind the reset plug on the front panel. Resetting can

be done when the temperature falls below 80°C.

Always check the cause of a guard being

triggered!

If the guards are triggered repeatedly,

the cause must be remedied!

11

14

17

16

18