22

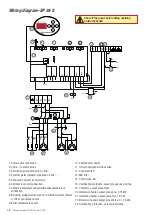

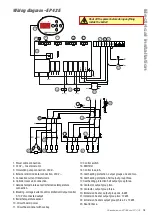

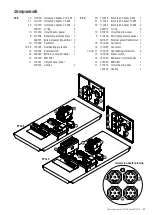

Värmebaronen EP 26E and EP 42E

Troubleshooting - Warning, limitation and alarms

Limitations

Reason

Explanation

Activation delay

Power-on limitation active. When boiler is restarted after power loss, it is connected

(if necessary): 1/3 of the output immediately, max 2/3 after 20 minutes and the remainder

40 minutes after power has returned.

In service mode, accelerated delay can be run. See menu item, Service level, row 2.

The time delay can also be permanently removed via menu item, Advanced Service level,

row 14.

The load guard limits

Green indicator flashes: The load guard limits.

For more information, see menu item, Installation/service level, rows 3-4.

External restriction/

blocking

Green indicator flashes: external limit.

0 – 10V on the input corresponds to 0 – 100% of installed output.

Manual operation

Manual selection to activate selected number of steps, control circulation pump and

buzzer alarm. For more information, see menu item, Advanced Service level, rows 18-22.

ECO mode

Green indicator flashes: ECO mode active.

Control function is enabled via the Menu, User level, row 12.

Warnings

The display shows current warnings if no stop alarms occur. The information remains until OK is pressed and the cause of the

warning has been resolved.

Reason

Explanation

High temperature around

the PCB.

Yellow indicator flashes: temperature above 45° C, yellow indicator goes off: temperature

below 42° C and the warning is acknowledged with OK.

Output steps down: Temperature above 55° C output steps in: Temperature below 45° C

High boiler temperature

Yellow indicator flashes: warning for overtemperature.

Yellow indicator goes off: the temperature has fallen below the limit and the warning is

acknowledged with OK.

Selectable via Menu, Advanced Service level, rows 16-17. At overtemperature, the

connected output steps out and steps in again only when the temperature has dropped

below the limit.

Low boiler temperature

Yellow indicator flashes: boiler temperature below 7° C. The boiler must always be at least

7° C during operation regardless of the specified setpoint.

If external blocking/external control is active, the boiler is NOT allowed to step in output.

If the load guard restricts, the boiler must NOT step in output.

Outdoor sensor

Yellow indicator flashes: incorrect value, interruption/short circuit on sensor and/or

disconnection of the outside sensor. Control assumes 0° C outdoor temperature.

Room sensor

Yellow indicator flashes: incorrect value, interruption/short circuit on sensor and/or

disconnection of room sensor. The room sensor is disconnected from the control until

the alarm is acknowledged and the sensor is repaired.

Room sensor, handwheel

setting

Yellow indicator flashes: incorrect value, interruption/short circuit or disconnection

of the setpoint. The room sensor is disconnected from the control until the alarm is

acknowledged and the sensor is repaired.

Stop alarm - Boiler blocked

Display shows current alarms. The information remains until the cause is corrected and OK is pressed

Reason

Explanation

Boiler temperature sensor

Red indicator flashes: incorrect value or interruption/short circuit on sensor.

Temperature sensor on

circuit board

Red indicator flashes: incorrect value or interruption/short circuit on sensor.

Low boiler temperature

Red indicator flashes: boiler is blocked at boiler temperature below 3° C.

Overheat protection is

trigged

Red indicator flashes: an alarm is blocking the boiler. All relays/contactors release,

circulation pump continues to run.

Low input voltage

Red LED flashes: excessively low supply voltage to electronics.

The relay outputs on the control are blocked.