EP E

series

11-03

12

Illustrations may differ from the actual product

Allowing for printing errors and errors on proofs

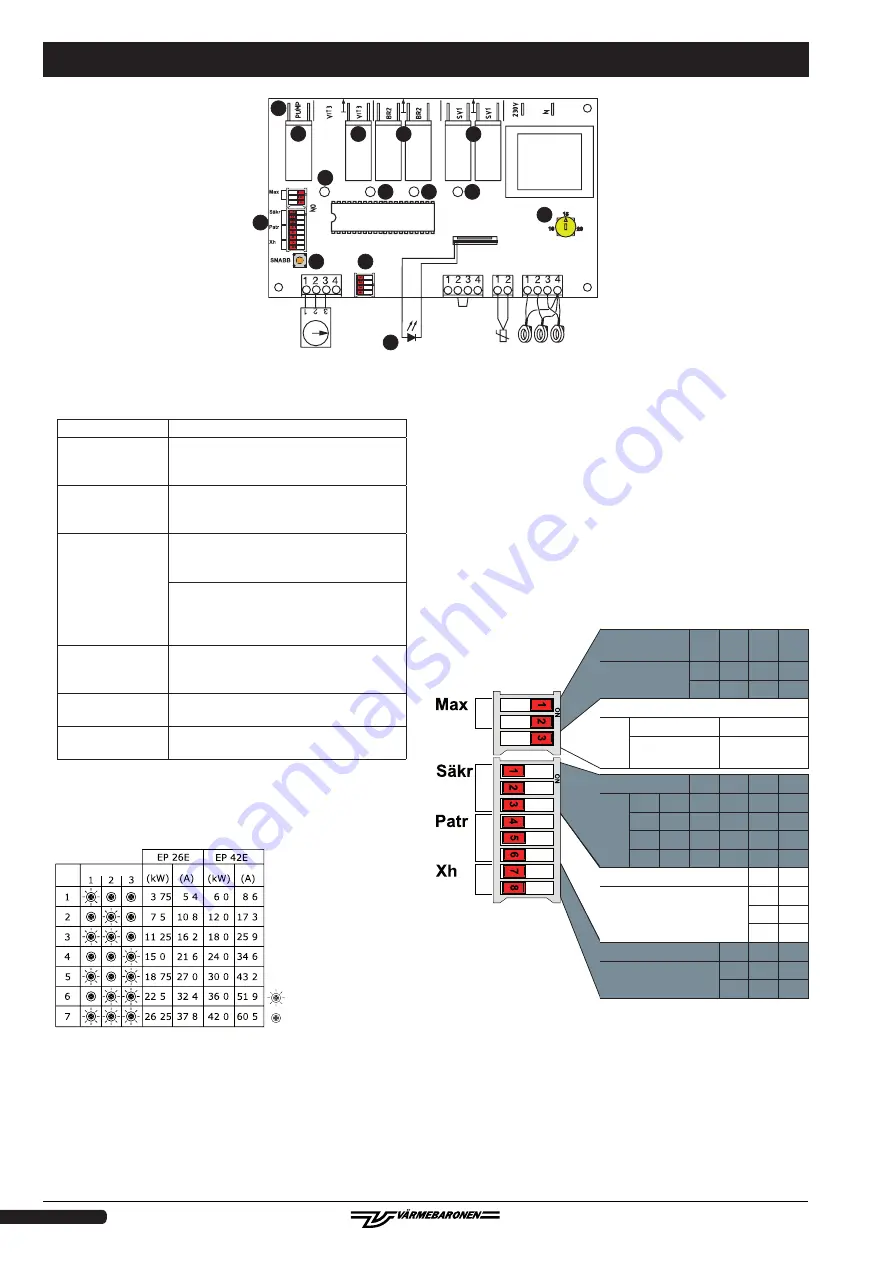

Electronic control system - settings

6. Power/status light.

Steady glow:

Normal operation.

One long

+

one short flash:

Power staging is limited by delayed

reconnection after a power cut.

One long

+

two short flashes:

Power staging is limited by the load guard,

the room thermostat or other external

control.

One long

+

three short

flashes:

A. Excess temperature: the power will be

reconnected when the temperature has

fallen.

B. Faulty temperature sensor: you must

replace the sensor before running the

boiler. To cancel the alarm, disconnect the

boiler for 10 seconds.

One long

+

four short flashes:

Remote control activated.

Rapid flashing

Bypassed delayed reconnection –

"SNABB" [FAST] button pressed.

Off:

No power (switch set to position O with

UTK E)

8. PCB.

The power is controlled with binary logic, which means that the

three power groups are connected as in the table below.

9. Indicator for power group one.

10. Indicator for power group two.

11. Indicator for power group three.

24. Temperature setting with remote control.

25. Switch for external block/remote control. See External block and

remote control, page 6.

26. Button to temporarily disable delayed reconnection after power

failure and to speed up the connection of power stages.

According to the standards, no more than 50% of the power can

be connected immediately after a loss of power lasting longer

than three minutes. The remaining power is delayed by an hour.

To test the boiler after it has been without power, for example

during installation or servicing, the delayed reconnection can

be disabled temporarily by pressing and holding the "SNABB"

[FAST] button until the status light stops flashing.

You can use the "SNABB" [FAST] to speed up the connection of

power stages for testing. Keep the button pressed for as long as

you need. The power may be limited by the load guard or by the

excess temperature protection.

27. Switch for setting operating parameters:

28. Relay outputs for power group one.

29. Relay outputs for power group two.

30. Relay outputs for power group three.

31. Output for circulation pump with summer mode/eco function

– the pump stops eight hours after the last time a power stage

is connected. The pump is operated briefly every twelve hours.

For best results, use UTK E to control the boiler. See point 27,

Circulation pump

Connected power group

Power group Power

Power

Current

Step

Non-connected power group

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Current

OFF

↔

ON

The factory settings are shown in bold.

Number of power

stages

7

6

5

4

(1&2)

ON

ON OFF OFF

ON

OFF ON OFF

Cirkulation pump

(3)

OFF

ON

eco/summer

mode

continuous

operation

Main fuse

EP42

EP26

(1-3) 125A 100A

80A

63A

50A

35A

ON ON

OFF

OFF

OFF

OFF

OFF OFF

ON

ON

OFF

OFF

ON OFF

ON

OFF

ON

OFF

Stage size

EP26 EP42

(4 - 6)

ON ON

Do not change this

parameter

ON ON

OFF ON

Delayed reconnection

2h

1h

0h

(7 & 8)

ON

OFF

OFF

OFF

ON

OFF

24

25

28

29

30

31

8

9

10

11

6

27

26

6