POWXG6026

EN

Copyright © 2014 VARO

P a g e

|

11

www.varo.com

11.6

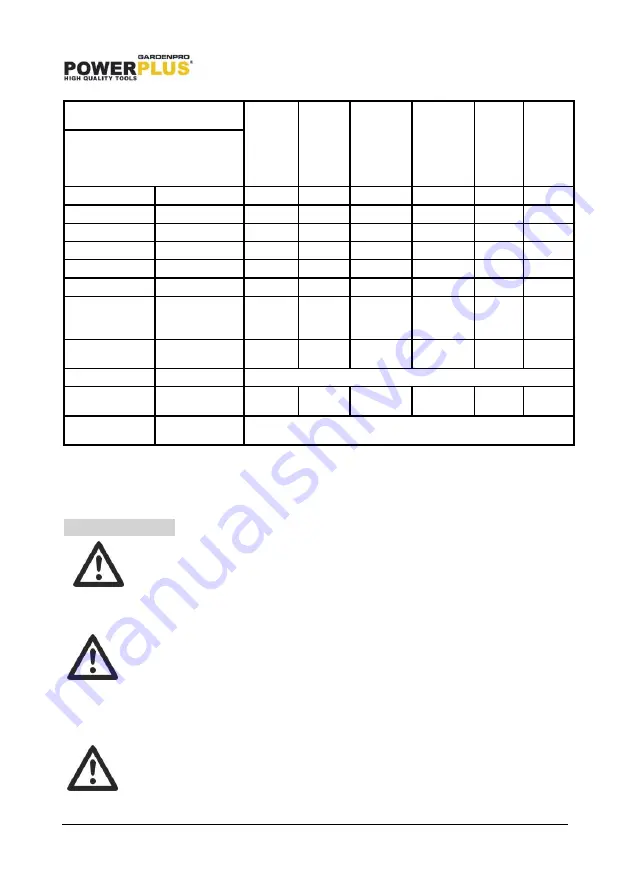

Maintenance schedule

REGULAR SERVICE PERIOD

(4)

Before

Each

Use

First

Month

or

5 Hrs

Every 3

Months

or

25 Hrs

Every 6

Months

or

50 Hrs

Every

Year

or

100

Hrs

Every

Two

Years

or 250

Hrs

Perform at every indicated

month or operating hour

interval, whichever comes

first.

Engine oil

Check

X

Replace

X

x (1)

Air cleaner

Check

X

clean(2)

clean(2)

Replace

X

Spark plug

Check/adjust

X

Replace

X

Flywheel

brake pad (A

types)

Check

X

Fuel tank and

filter

Clean

X (3)

Fuel tube

Check

Every 2 years (Replace if necessary) (3)

Valve

clearance

Check-adjust

X (3)

Combustion

chamber

Clean

After every 200 hours (3)

(1) Service more frequently when used in a dusty areas.

(2) Change oil every 25 hours when used with heavy load or in high ambient temperatures.

(3) These items should be serviced by a technician.

(4) For commercial use, record hours of operation to determine proper maintenance intervals.

12 CLEANING

CAUTION: Do not hose the engine. Water can damage engine or

contaminate the fuel system.

Wipe deck with dry cloth.

Hose under deck by tilting the mower so that the spark plug is up.

Do not tilt mower more then 30° towards the rear. If you want to tilt it more,

first drain fuel tank completely (see 11.3).

12.1

Cleaning the air filter

Remove the air filter cover, and take out the filter element. To avoid objects from falling into

the air chamber, attach the air filter cover again. Wash the filter element with warm soapy

water, rinse it carefully, and let it dry in the open air.

Warning! Never run the engine without the air filter element in place.

The following items are deemed as critical for safety:

Cutting blade and cutting blade holder.