POWXG6026

EN

Copyright © 2014 VARO

P a g e

|

9

www.varo.com

-Regularly clean the sideward flap and discharge opening form grass rest and stuck dirt.

10.3

Mowing tips

Under certain conditions, such as very tall grass, it may be necessary to raise the cutting

height to reduce resistance ( prevent overload of the engine) and leaving clumps of grass

clippings. It may also be necessary to run the lawn mower over the area a second time.

For extremely heavy cutting, reduce the width of cut by over lapping previously cut paths

and mow slowly.

The pores in the cloth grass catcher can become blocked with dirt and dust and will collect

less grass. To prevent this, regularly hose down the grass catcher and let dry before re

using.

Keep the top of the engine (around the starter) clear and clean of grass clippings and

chaff. This will help engine air flow and extend engine life.

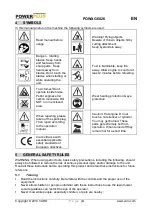

11 MAINTENANCE

IMPORTANT - Regular, careful maintenance is essential for keeping the safety level and

original performance of the machine unchanged in time.

Keep all nuts, bolts and screws tight to be sure the equipment is in safe working condition.

Regular maintenance is essential for safety and performance.

Never store the equipment with fuel in the tank inside a building where fumes can reach

an open flame, a spark or a source of extreme heat.

Allow the engine to cool before storing in any enclosure.

To reduce the fire hazard, keep the engine; exhaust silencer, battery compartment and

petrol storage area free of grass, leaves, or excessive grease. Do not leave containers

with grass cuttings in doors.

Replace worn or damaged parts for safety. For reasons of safety, do not use the

equipment with worn or damaged parts. Parts are to be replaced and not repaired. Parts

that are not of the same quality can damage the equipment and be dangerous for your

safety.

If the fuel tank has to be drained, this should be done outdoors and when the engine is

cool.

Wear strong work gloves when removing and reassembling the blade.

Check the blade's balance after sharpening.

Check the self-closing guard and grass-catcher frequently for wear and deterioration.

Whenever the machine is to be handled, transported or tilted you must:

wear strong working gloves;

grasp the machine at the points that offer a safe grip, taking account of the weight and its

distribution.

11.1

Oil (fill / check)

Before each subsequent use the oil level must be checked and if necessary topped up with

SAE30 engine oil.

Put on your mower on a level surface.

Unsrew & remove the oil cap/dipstick (7) on the side of the engine, the oil level must be

between upper (max.) & lower (min.) limit.

CAUTION : DO NOT overfill engine with oil, or it will smoke heavily from the muffler on start-

up

Re-tighten oil cap securely;

Wipe clean spilled oil.

Important: Change oil every 50 hours or every season.