POWEG2010

EN

Copyright © 2021 VARO

P a g e

|

9

www.varo.com

8 FUEL AND LUBRICATION

8.1

Fuel

Use regular grade unleaded gasoline mixed with 40:1 custom 2-cycle engine oil for best

results. Use mixing ratios in section fuel mixing table below.

Warning: never use straight gasoline in your unit. This will cause

permanent engine damage and void

the manufacturer’s warranty for that

product. Never use a fuel mixture that has been stored for over 90 days.

Warning: 2-cycle lubricant must be a premium grade oil for 2-cycle air

cooled engines mixed at a 40:1 ratio. Do not use any 2-cycle oil product

with a recommended mixing ratio of 100:1. If insufficient lubrication is the

cause of engine damage, it voids the manufacturer’s engine warranty.

8.2

Mixing fuel

Add oil to an approved fuel container followed by the gasoline to allow incoming gasoline to

mix with oil. Shake container to ensure thorough mix.

Warning: Lack of lubrication voids engine warranty. Gasoline and oil must

be mixed at 40:1

8.2.1

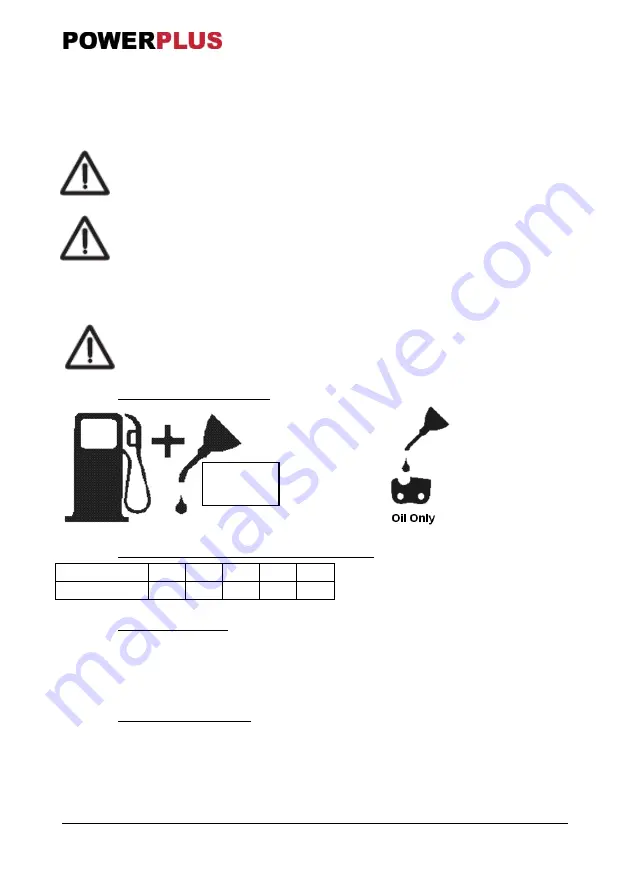

Fuel and lubrication symbols

8.2.2

Mixing ratio: 40 parts gasoline to 1 part lubricant

Gasoline liters

1

2

3

4

5

2-cycle oil ml

25

50

75

100

125

8.2.3

Recommended fuels

Some standard petrols are enriched with oxygen-containing compounds such as alcohol or

ether to comply with regulations on clean air. The motor is designed to work well on any car

petrol, including these enriched petrols, on the condition that the above mixing ratios are

observed!

8.2.4

Chain and bar lubrication

Always refill the chain oil tank each time the fuel tank is refilled. We recommend using our

replacement chain & bar. Always use good quality chain oil, which contains additives to

reduce friction and wear and to assist in the prevention of pitch formation on the bar and chain

9 OPERATION

9.1

Engine pre start checks (Fig 8)

40:1