POWP1010

EN

Copyright © 2018 VARO

p a g e

|

8

www.varo.com

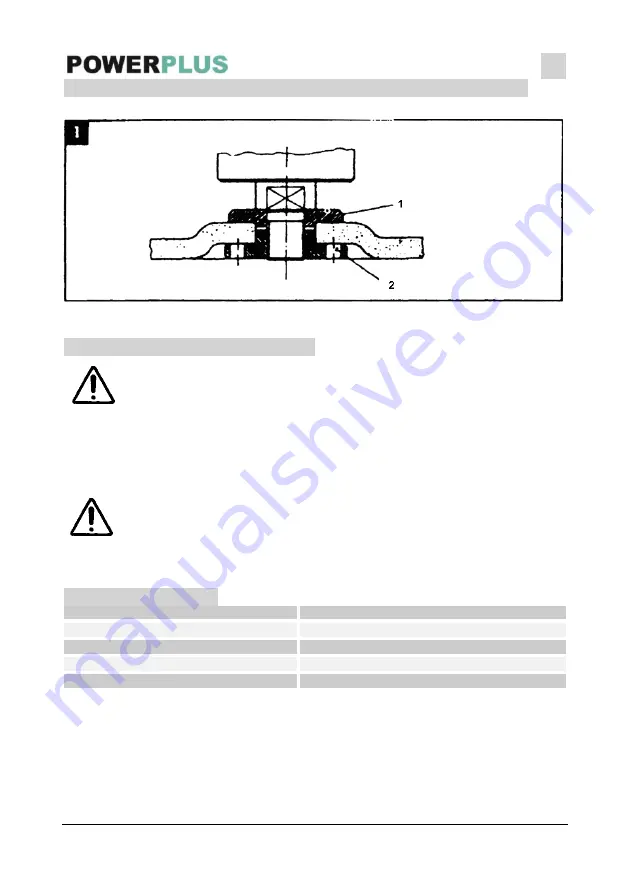

9 FLANGE ARRANGEMENTS WHEN USING GRINDING WHEELS

9.1

Flange arrangements when using a depressed centre or straight grinding wheel

1 Clamping flange

2 Flange nut

10 CLEANING AND MAINTENANCE

Attention! Before performing any work on the equipment, pull the power

plug.

10.1

Cleaning

▪

Keep the ventilation slots of the machine clean to prevent overheating of the engine.

▪

Regularly clean the machine housing with a soft cloth, preferably after each use.

▪

Keep the ventilation slots free from dust and dirt.

▪

If the dirt does not come off use a soft cloth moistened with soapy water.

Never use solvents such as petrol, alcohol, ammonia water, etc. These

solvents may damage the plastic parts.

10.2

Lubrication

The machine does not require any specific lubrication.

11 TECHNICAL DATA

Voltage / frequency

220-240 V / 50 Hz

Power input

720 W

No load speed

11500 min-1

Max. disc diameter:

Ø 115 mm

Drive spindle thread:

M 14