Assembly

Heater Wire Connections

Heater Wires (tan wires) have

push on connectors. Attach

either wire onto either open

terminal (indicated on the left)

on the heat control.

It does not matter which wire

to which terminal. Align the

connector with the tab on the

heat control and

push firmly

until fully seated

. It should be

hard to push them on, we want

a tight connection. Pull gently

on each connector, it should be

held firmly onto the tab.

!

Push any extra slack in the wires, back

up thru the hole in the conveyor bed.

See photo

10B

for

Ground Wire Connection

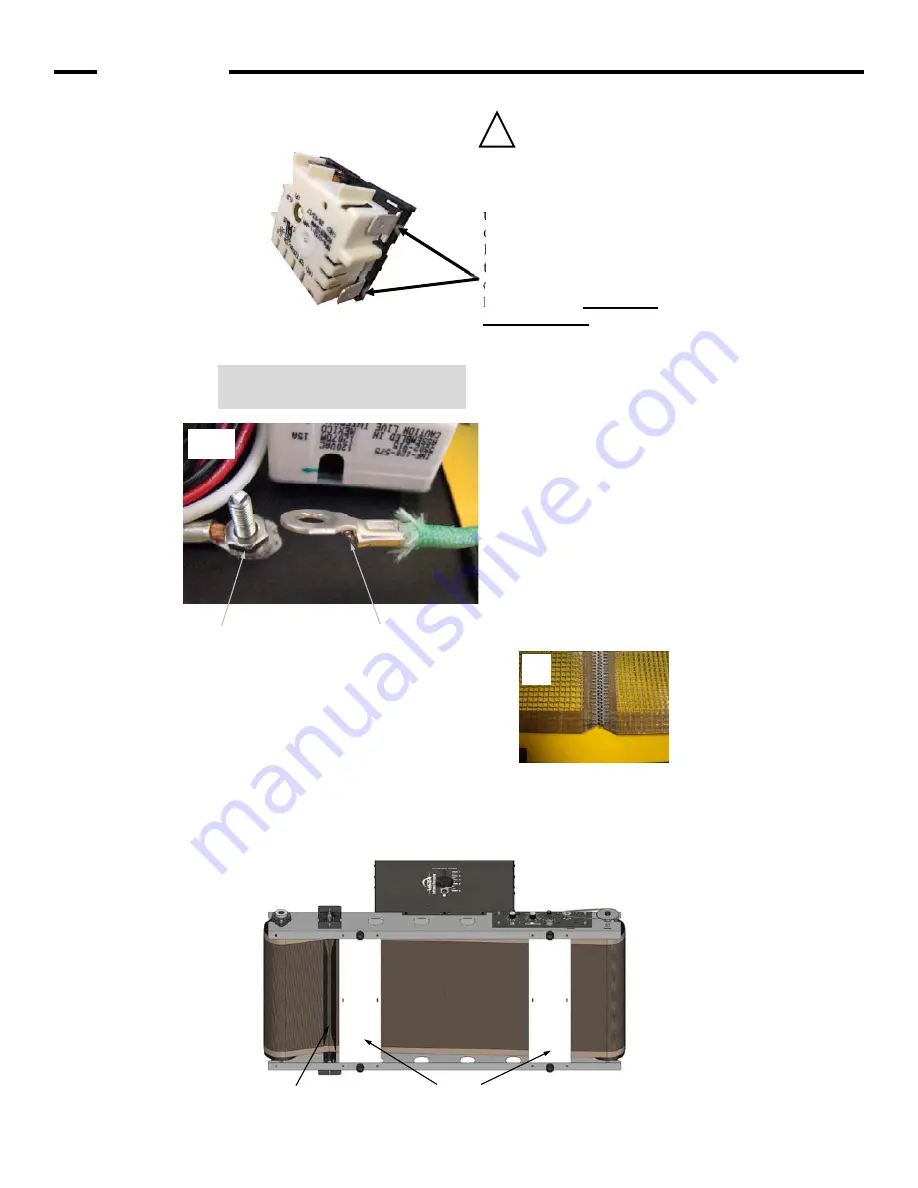

10B. Ground Wire Connection

Remove the wingnut and lock washer.

Place the green ground wire with the ring

terminal oriented as shown, onto the

grounding stud. Secure with lock washer

and wingnut.

Tighten nut securely.

Grounding Stud

Ring Terminal

10A

10B

Belt Installation

1) While dryer is on its side, pass the belt over the aligner

bar and both braces.

2) Carefully lay the dryer back onto its feet.

3) Align the edges of the belt and insert the belt connecting

pin. See enlarged view below.

4) Center belt on both rollers. Raise both sides of the belt

aligner equally approximately 1-1/2”.

Do Not

over tension belt, tension only enough to eliminate

any belt slip on drive pulley.

Belt Installation and Tracking

Braces

Aligner Bar

11

Align the edges of the belt.

Insert the belt connecting pin.

Pin ends can be trimmed if desired

11

Pg. 10

Summary of Contents for D-100

Page 16: ......