ce

rti

fied

QM-Sys

tem

g

ep

rüfte

s Q M-S

ys

te

m

ISO 9001

EN 29001

Installation, Operating, and Maintenance Instructions

Series 021

VAT Vakuumventile AG, CH-9469 Haag, Switzerland

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vat.ch

205440EC

2003-04-14

7/12

Preventive Maintenance

The italicized numbers refer to the detail drawings in this chapter and to the drawings in chapter «Spare parts».

Under clean operating conditions, the valve does not require any maintenance during the specified cycle life

(see chapter «Technical data»).

Preventive maintenance actions include replacing gate, bellows, and piston seals. Also, the pneumatic

parts are relubricated, and the valve body is cleaned. Other parts are checked and replaced if necessary.

For repair or case of emergency, VAT recommends to keep at least the following spare parts on site :

−

1

MONOVAT

gate

−

2

bellows

assembly

−

1 complete gate/actuator assembly (minimizes MTTR)

Cleaning or Replacing Gate

1. Vent chambers and open valve

2. Disconnect valve from compressed air and electrical supply

3. Unfasten bonnet screws 65 and remove gate/actuator assembly carefully

4. Loosen screws 44 by 1 turn to withdraw gate from shafts

5. Clean or replace gate, reassemble in reverse direction. Tighten gate screws 44 with 5 Nm.

Replacing Bellows

1. Remove gate as described above

2. Remove cover sheets 15 (2x) with screws 47 (4x per sheet)

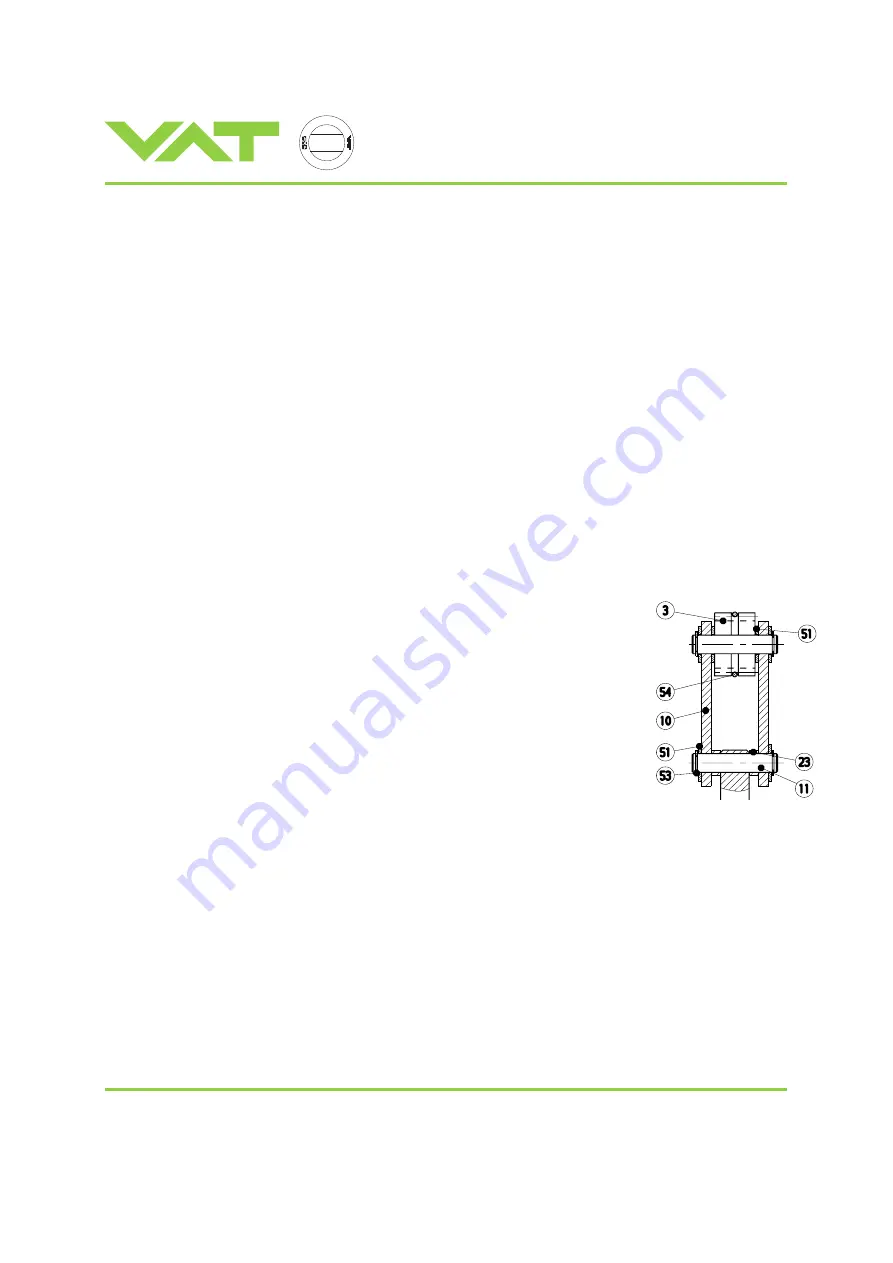

3. Remove circlip 53, distance rings 23 (2x), and bolt 11 (see detail)

4. Unfasten screws 40 (8x) and remove bonnet 64

5. Pull out bellows assembly 2 carefully

Note : Do not contaminate O-rings 30 and tube 17 with any dirt or lubricant.

6. Mount new bellows assembly 2, O-rings 30 (2x per bellows) and tube 17 (1x per bellows)

Note : Handle new bellows assembly with gloves.

7. Reassemble in reverse direction

Please note :

−

Do not contaminate the vacuum side of the bellows with any lubricant.

−

The shaft of replacement bellows assembly is lubricated at the factory for the shaft bushing.

−

Actuator has a leak detection port (marked on drawing) for the bellows assembly.

Replacing Piston seals:

1. Remove gate and cover sheets as described above

2. Unfasten screws 40 (8x) and remove bonnet 64

3. Remove nut 55 and lug 22, and pull out piston 14 and shaft 13

4. Replace piston O-ring 32 and shaft seal 33, replace static O-rings 31, 35, 36 if damaged

5. Lubricate cylinder and piston with VAT high temperature pneumatic grease

6. Reassemble in reverse direction