ce

rti

fied

QM-Sys

tem

g

ep

rüfte

s Q M-S

ys

te

m

ISO 9001

EN 29001

Installation, Operating, and Maintenance Instructions

Series 021

VAT Vakuumventile AG, CH-9469 Haag, Switzerland

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vat.ch

205440EC

2003-04-14

8/12

A

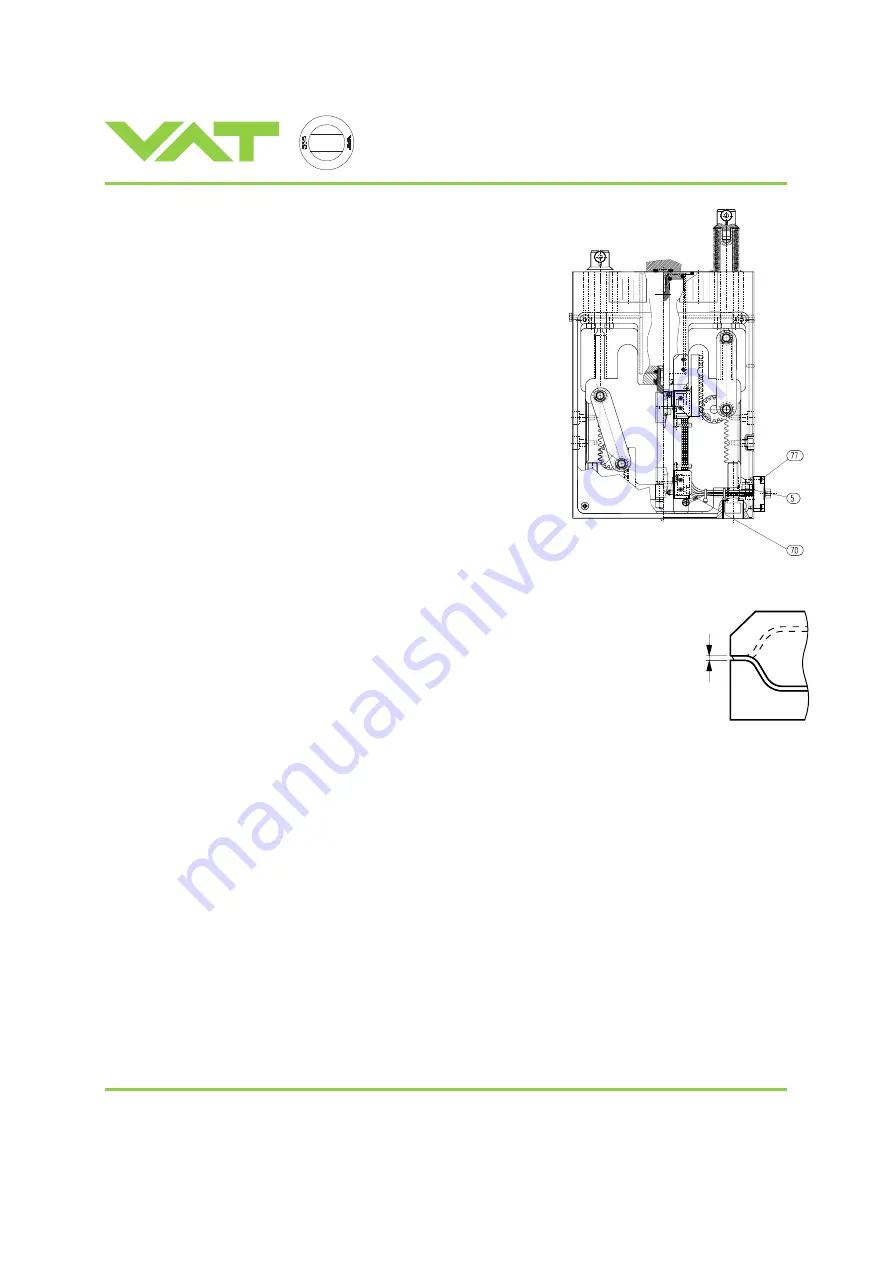

Replacing Position indicator

1. Disconnect valve from compressed air and electrical supply

2. Remove cover sheets 15 (2x) with screws 47 (4x per sheet)

3. Unfasten screws 77 (4x), wire wrap and screws 70 (2x per assembly)

4. Pull mounting bar downwards out of it’s slot in the actuator house.

5. Pull out insert 5 (to the left) and remove position indicator.

6. Reassemble in reverse direction

The switch point can be readjusted by loosening the screws of the switch

and moving the switch in the slotted holes of the mounting bar. The switch

point should be set 1 to 1.5 mm prior to the end positions.

Adjustment of Actuator

The compression of the gate seal is adjusted and tested at our factory and must normally not be readjusted.

Verification of Adjustment

−

Gap «A» between gate and seat (see sketch beside) should be 3.0 mm ±0.15 mm

−

Gate and seat should be parallel within 0.2 mm

−

During closing the mechanical locking should occur between 1.0 and 1.2 bar air pressure

To check this : 1. Reduce air pressure below 0.5 bar

2. Command valve in closed position

3. Increase air pressure until a clicking sound indicates the mechanical locking

Adjustment of Compression and / or Parallelism

1. Open valve

2. Loosen screws 43 (2x per rack) of racks 12 (2x)

3. Adjust compression of gate seal by turning both screws 42 by the same angle

Note : Turning screws 42 by 30° results in 0.125 mm change of compression.

4. Adjust parallelism by turning one screw 42

Note : Turning one screw 42 by 30° results in 0.125 mm change of compression on the respective side

5. Fasten screws 43 (4x)

6. Open and close valve, verify again compression and parallelism, repeat adjustment if necessary

Lubrication of Valve

−

Gaskets in the vacuum area are not lubricated. Small amounts of a suitable high vacuum grease (VAT high

performance vacuum grease) may be used to lubricate O-rings or gate seal.

−

Lubricate pneumatic cylinder and piston seals with VAT high temperature pneumatic grease. Other lubricants may not

meet our cycle life specification.

−

Lubricate gears, racks, and lashes in the actuator with Rocol or equivalent.

−

Lubricate screws outside the vacuum with Molykote 321 R or equivalent. Screws supplied by VAT are lubricated.

−

Pneumatic cylinder and actuator parts must be relubricated after the specified cycle life (see chapter «Technical

data»). The shaft of new bellows assembly is lubricated at the factory.