Installation, Operating & Maintenance Instructions

Series 650 DN 350 (I.D. 14”), CC-Link

VAT Vakuumventile AG, CH-9469 Haag, Switzerland

Tel +41 81 771 61 61 Fax +41 81 771 48 30 CH@vatvalve.com www.vatvalve.com

286241EA

2010-10-11

8/86

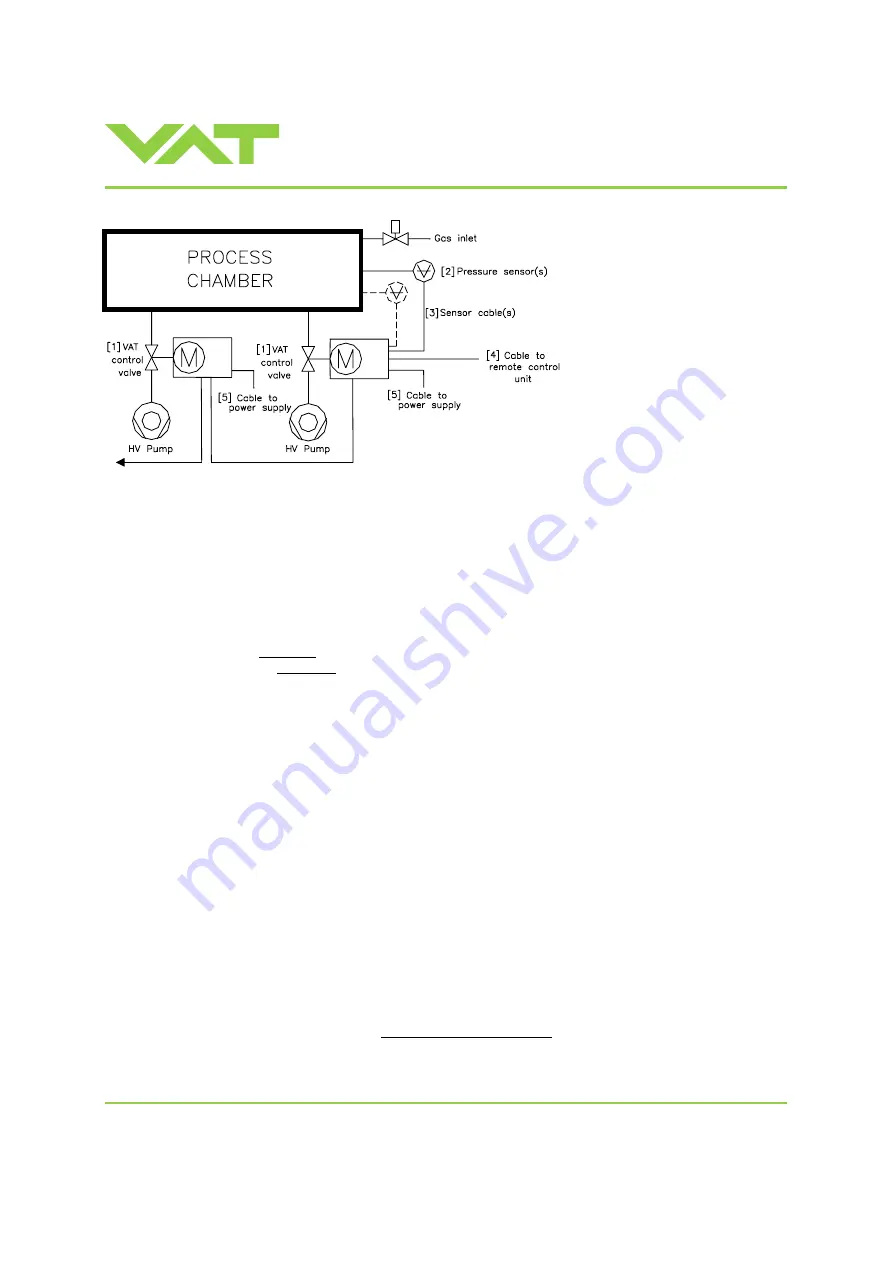

1. Install valves [1] into the vacuum system. Valve seat side should face process chamber. The valve seat side is

indicated by the symbol "

∇

" on the valve flange.

Caution: Do not tighten the flange screws stronger than indicated under «Tightening torque».

Caution: Do not admit higher forces to the valve than indicated under «Admissible forces».

Note: Make sure that enough space is kept free to do preventive maintenance work. The required space is indicated

on the dimensional drawing.

2. Connect compressed air supply to connection labeled ‘IN’ located at actuator, see Figure 1 below.

Connect compressed air return line connection labeled ‘OUT’ located at actuator, see Figure 1 below.

Caution: Compressed air pressure must be in the range of: 4 - 7 bar / 55 - 100 psi (above ATM).

Note: Use only clean, dry or slightly oiled air. IN / OUT connections are 1/8“ ISO/NPT internal threads.

3. Install the ground connection cable at controller. Refer to «Electrical connection»

4. Install pressure sensor(s) [2] according to the recommendations of the sensor manufacturer and directives given

under

«Requirements to sensor connection».

5. Connect sensor cable [3] to sensor(s) and then to Master valve (connector: SENSOR).

Refer to chapter «Electrical connection» for correct wiring.

Note: 65051-JAWL-0001 supports 1 sensor(s).

6. Connect Master valve to CC-Link [4] (connector: INTERFACE). Refer to «CC-Link schematics» for correct wiring.

7. Enable terminating resistor in link adapter of first and last valve in the system. Refer to «Valve cluster connection» for

details.

8. Connect link cable [6] between Slave valve(s) and Master valve (link adapter). Refer to «Valve cluster connection» for

correct wiring.

9. Connect power supply [5] to each valve (connector: POWER). Refer to chapter «Electrical connection» for correct

wiring.

Note: To provide power to the valve motor pins 4 and 8 must be bridged, otherwise motor interlock is active and the

valve enters the safety mode and is not operative. Refer also to «Safety mode».

Master

Slave

[6] Link cable

[6] Link to next Slave