EN

DynamiTe fuze 540 4-pole 3300kV sensorless brushless moTor

PrecautionS

»

Never touch moving parts.

»

Never disassemble while the batteries are installed.

»

Always let parts cool before touching.

adjuStinG tHe SliPPer

Turn the 5mm adjustment nut clockwise (to the right) to reduce

the slip or counterclockwise (to the left) to increase the slip.

cHanGinG tHe Pinion Gear/Gear ratio

Your vehicle comes with the 20T pinion gear. To change to an-

other pinion gear (sold separately), follow the directions below.

1

Unscrew the 3 screws holding the gear cover/motor mount

in place.

2

Remove the motor gear cover.

3

Remove the pinion gear.

4

Remove the screws holding the motor and move to the

appropriate holes (marked with the number of teeth on

the pinion) and reinstall the screws.

5

Place the new pinion gear on the motor shaft.

6

Reinstall the gear cover.

GearinG

Your vehicle has been equipped with the

optimal gearing for the stock platform. It

offers an ideal balance between speed,

power and efficiency. Should you decide

to customize your vehicle with optional

batteries or motors, it may be necessary

for you to change the pinion or spur gear.

Installing a pinion gear with less teeth or

a spur gear with more teeth will provide

greater torque but will reduce top speed.

Likewise, a pinion gear with more teeth or

a spur gear with fewer teeth will reduce

torque and increase top speed. Care

should be taken when installing larger

pinion gears as this can “overgear” the

vehicle, resulting in overheating of the

motor and ESC. When testing differ-

ent gearing options, pay close atten-

tion to the temperature of the motor

and speed control to ensure you are

operating within the temperature range

of the components. The motor or ESC

should never be so hot that it cannot be

touched. If temperatures are too hot,

a different gearing combination with a

lower pinion gear and/or higher spur gear

is suggested.

To set the gear mesh, screw the motor into the corresponding

marked set of holes. For example, with a 20T pinion, the motor

screws must be screwed into the holes labeled “20”.

SettinG tHe Gear MeSH

The gear mesh has already been set at

the factory, and setting it is only neces-

sary when changing motors or gears.

Proper gear mesh (how gear teeth meet)

is important to the performance of the

vehicle. When the gear mesh is too loose,

the spur gear could be damaged by the

pinion gear of the motor. If the mesh is

too tight, speed could be limited and the

motor and ESC will overheat.

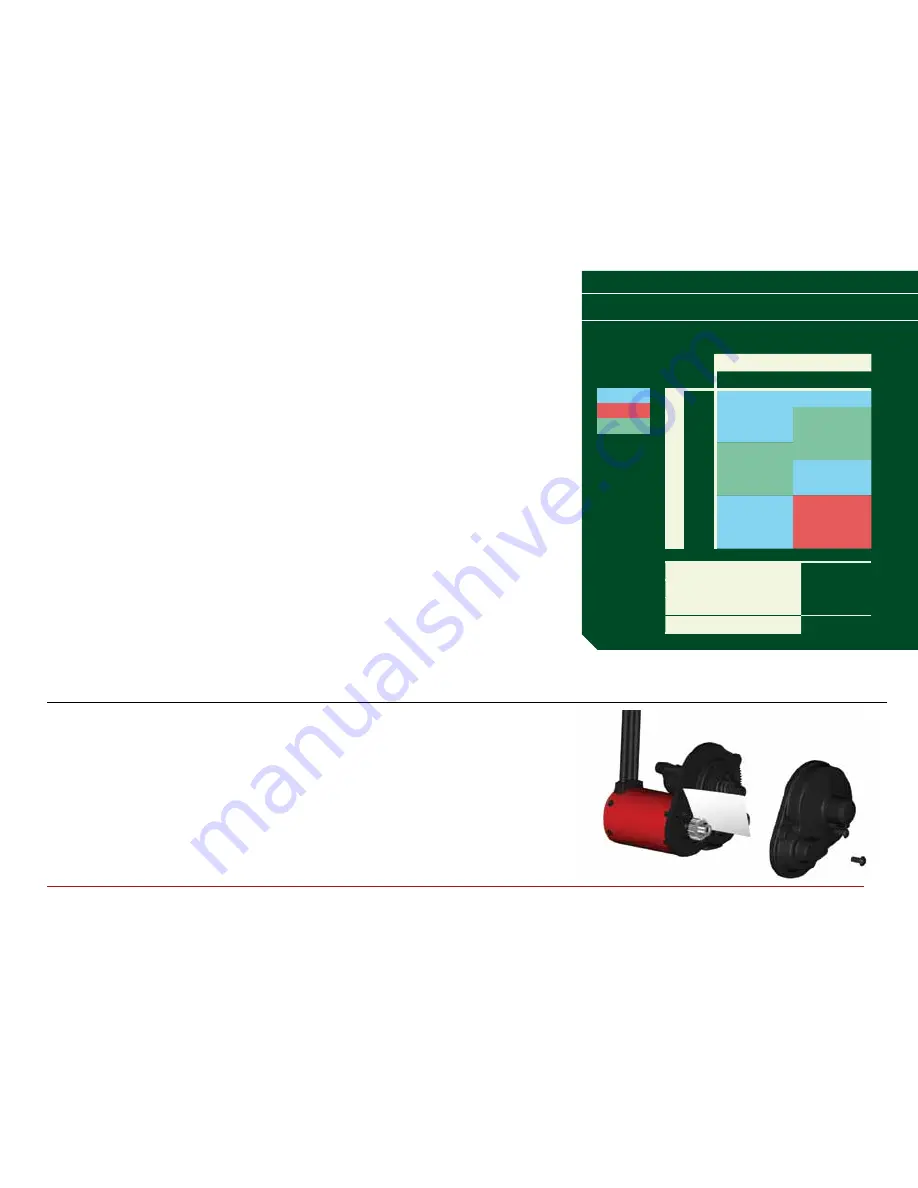

Gear CharT

/ / / / / / / / / / / / / / / / / / / / / / / / / / / /

final driVe ratio

2S

3S

Pinion

16T

14.52

14.52

17T

13.66

13.66

18T

12.91

12.91

19T

12.23

12.23

20T

11.61

11.61

21T

11.06

11.06

22T

10.56

10.56

23T

10.10

10.10

24T

9.68

9.68

internal Gear ratio

2.67

SPur

87

Pinion

20

final driVe ratio

11.61

Marginal

thermo

oK

final driVe ratioS

eXaMPle