USER MANUAL

Vauconsant SA, all rights reserved A622xx & E633xx -rev0-ENG, 2/12/2010 - 12 -

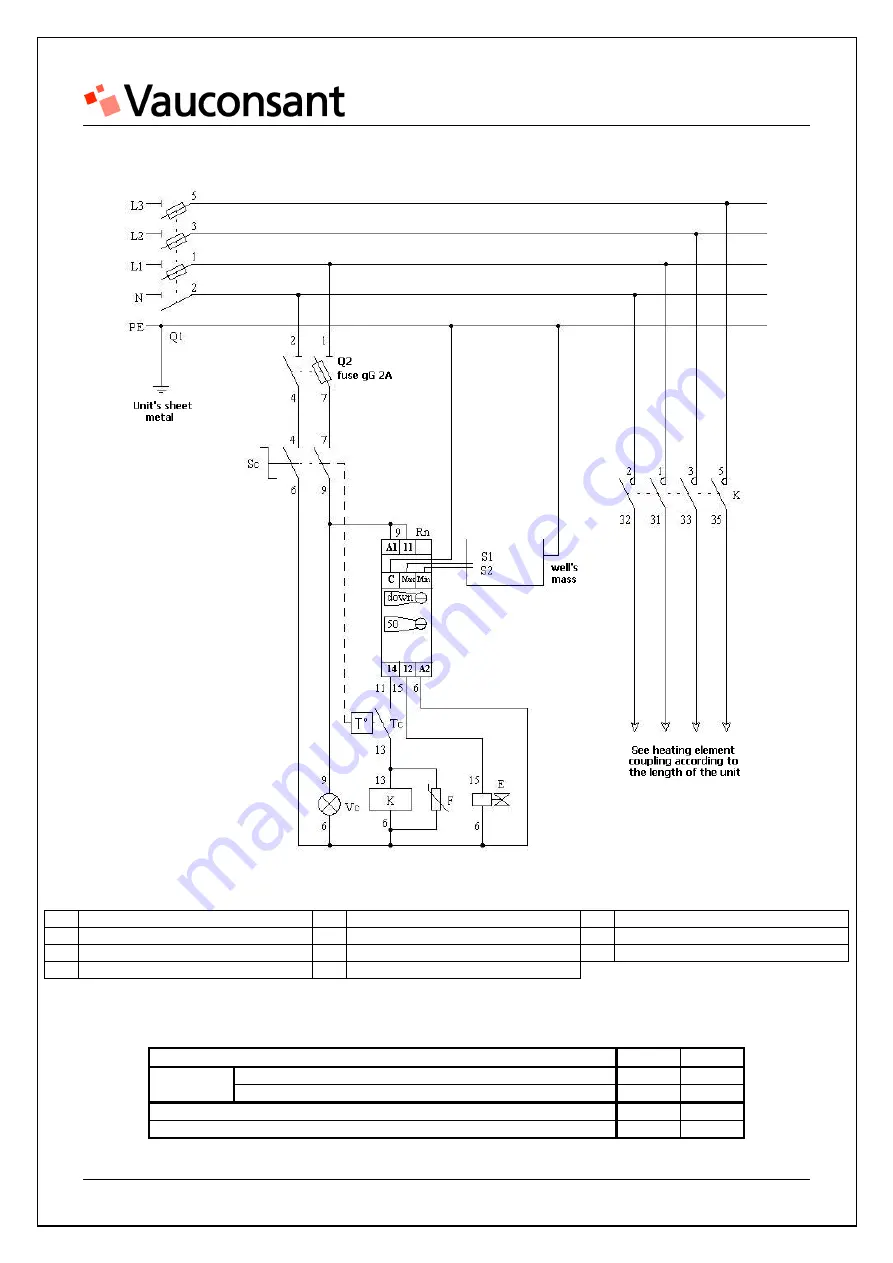

Three-phase without heating display

Caption

E Well filling solenoid valve

Q2 Solenoid valve's fuse holder

Sc Well's thermostat on/off

F Anti-parasite filter

Rn Water level relay

Tc Well’s thermostat

K Well heating contactor

S1 Maximum water level probe

Vc Well's heating light

Q1 Main fuse holder

S2 Minimum water level probe

Features

Unit reference

A62219

A62222

Number of heating elements: 415 mm, 750 W

5

6

Bain-marie

well

Power of the bain-marie well (W)

3 750

4 500

Unit's total power (W)

3 750

4 500

gG (A) fuse caliber

8

8