USER MANUAL

Vauconsant SA, all rights reserved A625xx -rev0-ENG, 14/10/2010 - 2 -

Manual to be read and kept

Contents

Introduction …………………………………………………………

3

Installation / Controls ……………………………………………...

4

Commissioning / Use ……………………………………………...

7

Cleaning / Diagnostic ……………………………………………..

8

Maintenance ………………………………………………………..

9

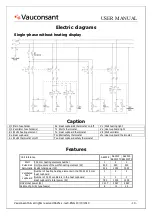

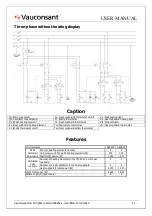

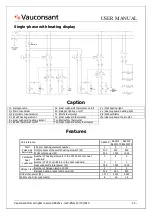

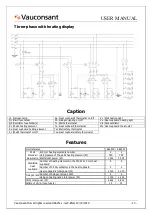

Electric diagrams ………………………………………………….

11

Spare parts …………………………………………………………

16

Technical support / Warranty …………………………..………...

17