12

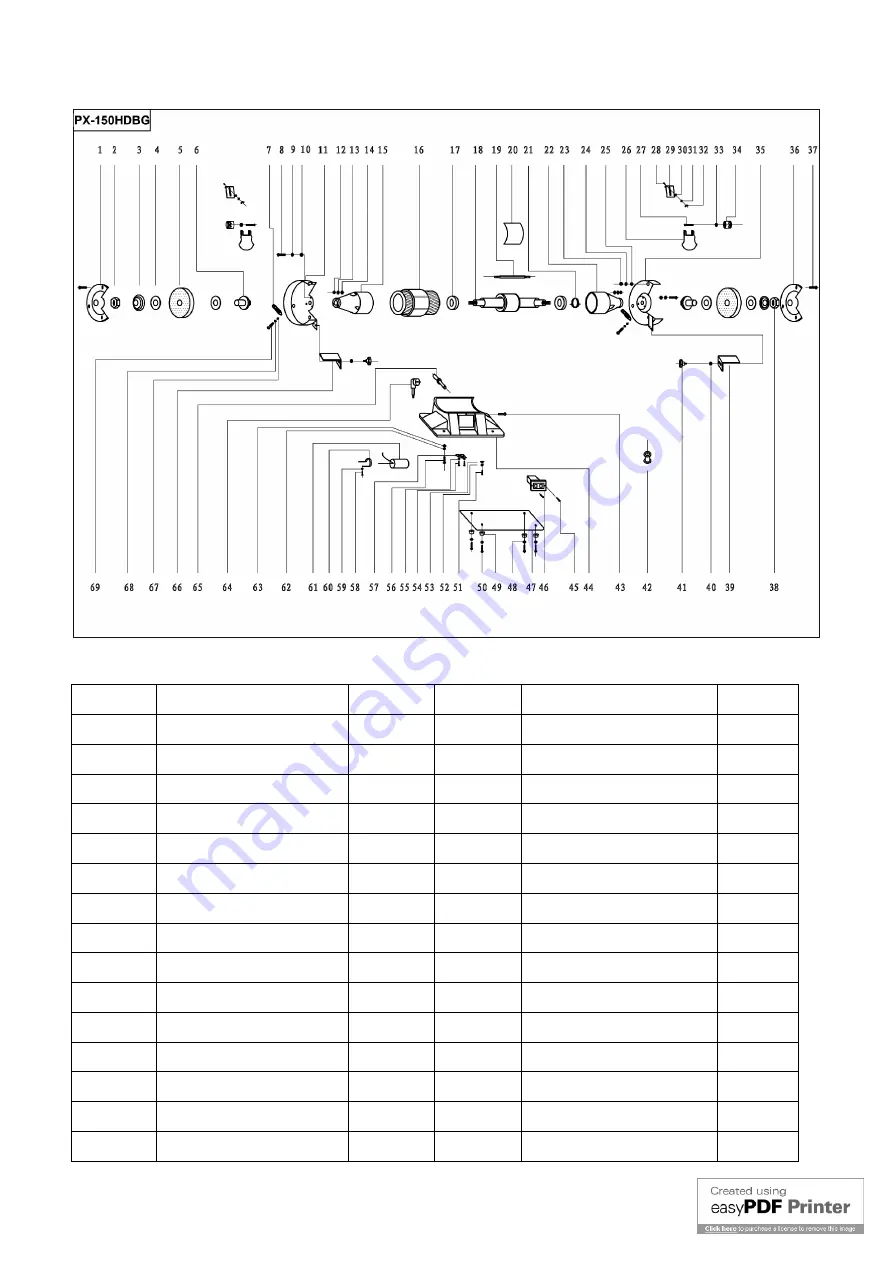

Exploded Drawing

Part List: PX-150HDBG

ITEM

DESCRIPTION

QTY

ITEM

DESCRIPTION

QTY

1

Left Outer Cover

1

38

Wheel Lock Nut

1

2

Wheel Lock Nut

1

39

Right Tool Rest

1

3

Outer Wheel flange

2

40

Washer

2

4

Nameplate of wheel

4

41

Knob Nut

2

5

Wheel

2

42

Cable protector

1

6

Inner Wheel flange

2

43

Bolt

3

7

Ash Tube

2

44

Base

1

8

Bolt

6

45

Bolt

2

9

Washer

6

46

Switch

1

10

Flat washer

6

47

Base plate

1

11

Left Inner Cover

1

48

Washer

4

12

Screw

6

49

Rubber feet

4

13

Washer

6

50

Bolt

4

14

Flat washer

6

51

Bolt

1

15

End cover

1

52

Washer

1