0

Futura FHD2/FMD2 E6

GENERAL INFORMATION

General information

1 - 8

0

DD1020_01

Applying locking compounds

The following procedure must be followed when applying

locking compounds to threaded connections:

1. Clean both the internal and external thread.

Remove any grease from the thread using a suitable

degreasing agent which leaves no residue that could

reduce the effectiveness of the locking compound.

2. Depending on the diameter, apply one or more drops of

locking compound to the thread. Never dip the bolt or

stud into the locking compound.

3. Apply a drop of oil under the bolt head. Locking com-

pounds also reduce the frictional resistance, so that no

oil has to be applied to the thread.

4. Tighten the connection to the specified torque.

1.2.2

SEALANTS

Certain cleaning agents have a negative

effect on the effectiveness of the sealant.

Therefore, the general rule is that after

fixings and components have been

cleaned with a cleaning agent, they must

be treated with a cleaning liquid to ensure

that the sealant functions correctly.

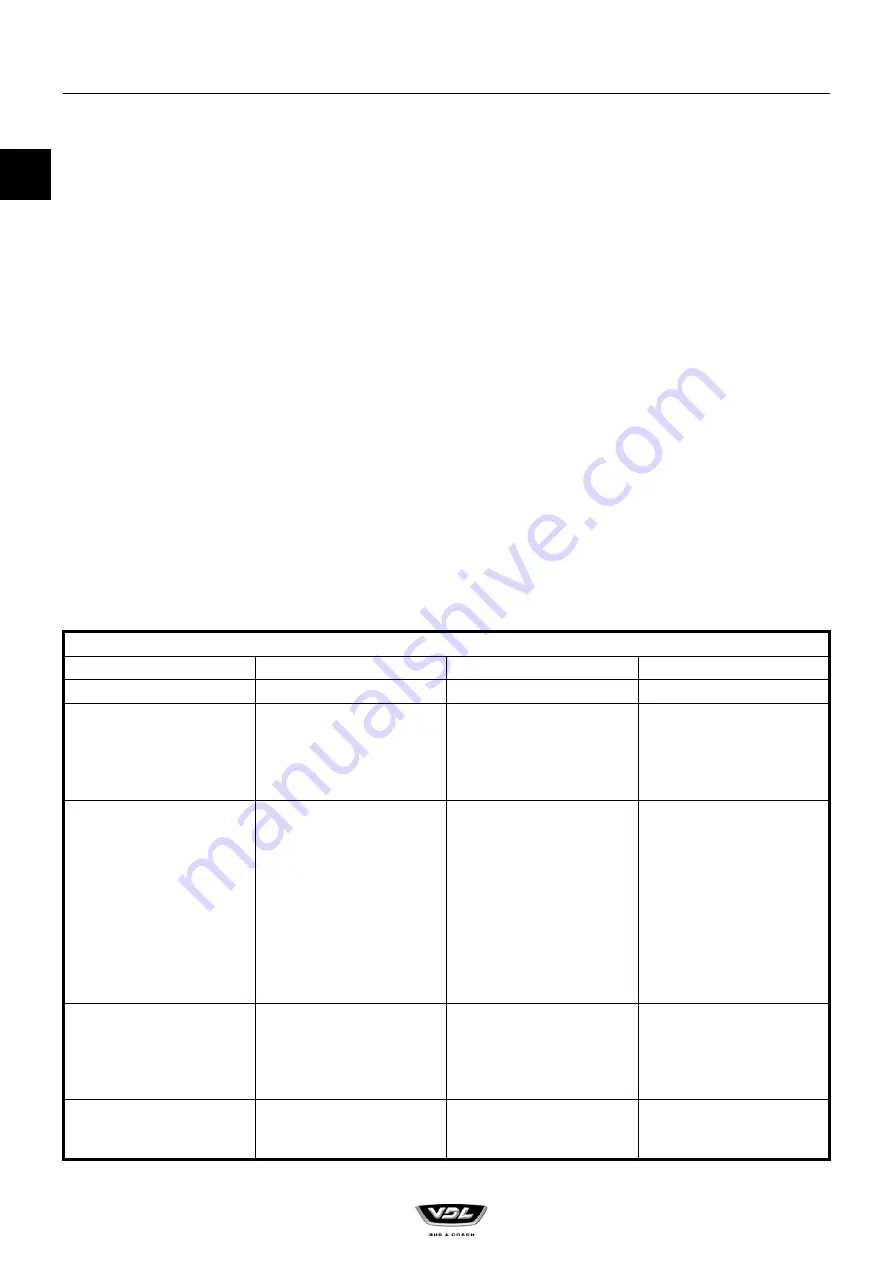

OVERVIEW OF SEALANTS

Product name

Properties

Use

Article number

Dirko D

Withstands temperatures

up to 180° C.

Resistant to oil and cool-

ant.

For sealing flush connec-

tions.

41345014

Dow Corning 752

Withstands temperatures

of -55° C to 220° C.

Processing time of less

than 15 minutes.

Maximum drying time of 24

hours.

Minimum sealing bead

thickness of 4 mm.

Silicon sealant for sealing

floor panels (feed-through

connectors, etc.).

40693628

Loctite 510

Withstands temperatures

up to 200° C.

Resistant to oil, brake fluid

and coolant.

For sealing flush (flange)

connections that are sub-

jected to high operating

temperatures, such as the

flywheel housing.

40697149

Loctite 518

Withstands temperatures

up to 150° C.

For sealing differential and

axle beam contact sur-

faces.

41357034

Summary of Contents for Futura FHD2 E6

Page 1: ...Futura FHD2 FMD2 E6 1525 DD1020_01 Main Group 0 WORKSHOP MANUAL...

Page 6: ...0 Futura FHD2 FMD2 E6 2 4 DD1020_01...

Page 7: ...0 Futura FHD2 FMD2 E6 GENERAL INFORMATION 0 DD1020_01 GENERAL INFORMATION...

Page 8: ...0 Futura FHD2 FMD2 E6 GENERAL INFORMATION 0 DD1020_01...

Page 23: ...0 Futura FHD2 FMD2 E6 SAFETY REGULATIONS 1 DD1020_01 SAFETY REGULATIONS...

Page 24: ...0 Futura FHD2 FMD2 E6 SAFETY REGULATIONS 1 DD1020_01...

Page 42: ...0 Futura FHD2 FMD2 E6 SAFETY REGULATIONS General information 1 18 1 DD1020_01...

Page 43: ...0 Futura FHD2 FMD2 E6 DIAGNOSIS 2 DD1020_01 DIAGNOSIS...

Page 44: ...0 Futura FHD2 FMD2 E6 DIAGNOSIS 2 DD1020_01...

Page 94: ...0 Futura FHD2 FMD2 E6 DIAGNOSIS Systems 2 26 2 DD1020_01...

Page 111: ...0 Futura FHD2 FMD2 E6 REPAIR GUIDELINES 3 DD1020_01 REPAIR GUIDELINES...

Page 112: ...0 Futura FHD2 FMD2 E6 REPAIR GUIDELINES 3 DD1020_01...

Page 122: ...0 Futura FHD2 FMD2 E6 REPAIR GUIDELINES General information 1 10 3 DD1020_01...

Page 132: ...0 Futura FHD2 FMD2 E6 LIQUID AND LUBRICANT GUIDELINES 4 DD1020_01...

Page 139: ...0 Futura FHD2 FMD2 E6 CLEANING INSTRUCTIONS 5 DD1020_01 CLEANING INSTRUCTIONS...

Page 140: ...0 Futura FHD2 FMD2 E6 CLEANING INSTRUCTIONS 5 DD1020_01...

Page 149: ...0 Futura FHD2 FMD2 E6 STORAGE AND PRESERVATION 6 DD1020_01 STORAGE AND PRESERVATION...

Page 150: ...0 Futura FHD2 FMD2 E6 STORAGE AND PRESERVATION 6 DD1020_01...

Page 155: ...0 Futura FHD2 FMD2 E6 PAINT TREATMENT 7 DD1020_01 PAINT TREATMENT...

Page 156: ...0 Futura FHD2 FMD2 E6 PAINT TREATMENT 7 DD1020_01...

Page 162: ...0 Futura FHD2 FMD2 E6 PAINT TREATMENT Paint treatment 1 6 7 DD1020_01...

Page 168: ...0 Futura FHD2 FMD2 E6 PAINT TREATMENT Anticorrosion antichip coating 2 6 7 DD1020_01...

Page 170: ...0 Futura FHD2 FMD2 E6 INSTRUCTIONS FOR JACKING UP AND SUPPORTING THE VEHICLE 8 DD1020_01...