Page 7

Duct and Duct Connections

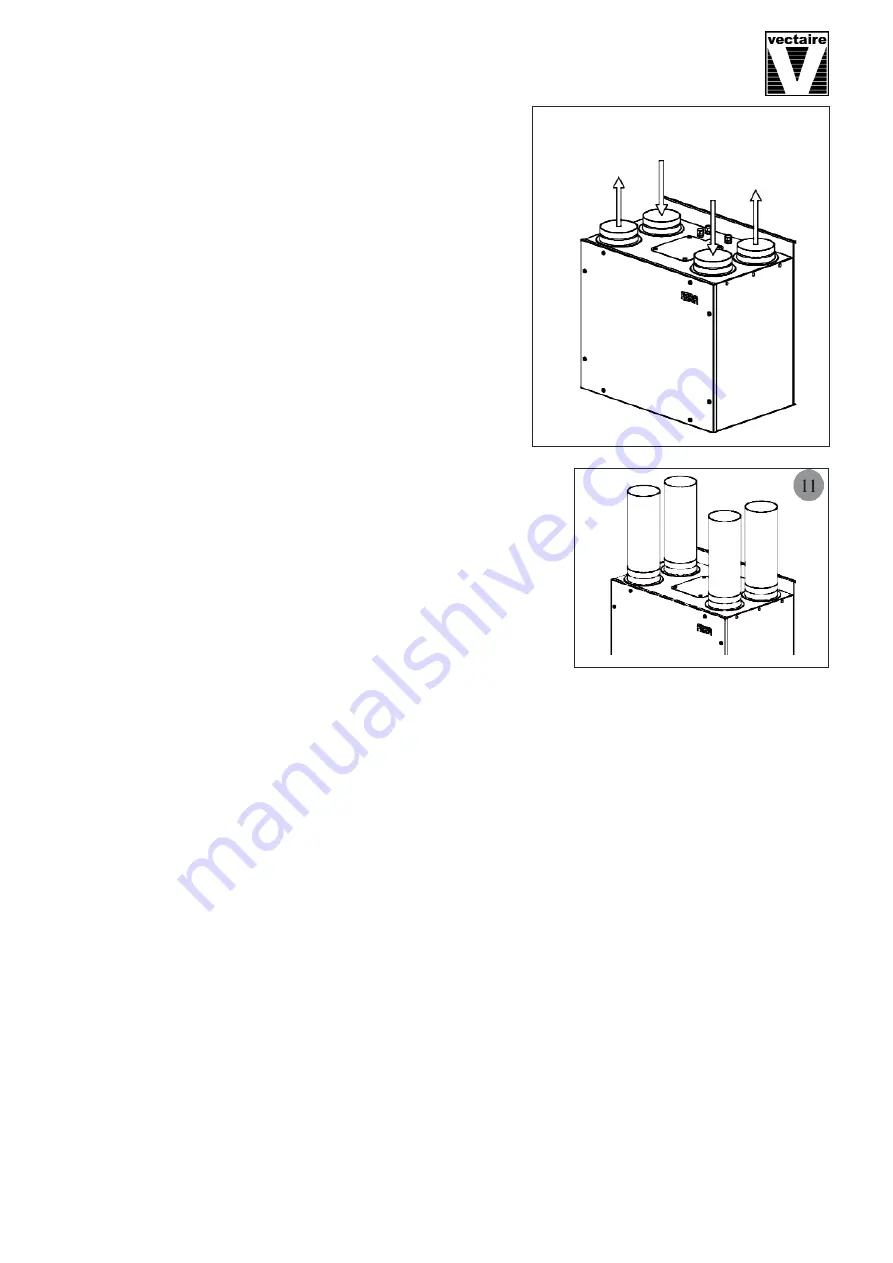

(refer to design drawing)

•

4 x 125mm nominal diameter spigots are provided for the

connection of ducting. These are clearly marked for correct

connection of the supply and exhaust ducts.

•

Where ducts are exposed in unheated areas, they should be

insulated (except for the exhaust duct from the unit to the

atmosphere),

•

The duct layout must be designed to suit the requirements of the

ventilation/heat recovery system and building layout.

•

Where rigid duct is used, it should be installed using the least

number of fittings to minimise air flow resist ance. Where

possible, final connection to the grilles and unit should be made

with a flexible connection.

•

Where flexible ducts are used, ensure that:

- lengths of ducting longer than necessary are

not

used

- the duct is stretched so that it is smooth and straight

- where bends are necessary, they have large radii (ie avoid

sharp bends)

- the duct is not crushed if in a restricted area

•

Where ducting passes through a fire partition, suitable fire

dampers

must

be installed to prevent the transmission of fire

through the duct.

.

Electrical Connection

WARNING: these appliances must be earthed and all wiring must conform to current IEE Regulations and all

applicable standards and Building Regulations.

• The unit is suitable for 230V, 50Hz Single phase supply fused at 3A.

• The unit is supplied with a mains rated 4 core flexible cord (black, brown, grey and green/yellow)

• A triple pole isolation switch with contact separation of at least 3mm must be used to connect the appliance

to the fixed wiring when using the Switched Live.

• Boost controls must not be located within 1 metre of a cooker or where they may be affected by excessive

heat or moisture,

• Boost controls should be clearly identified and conveniently located.

• The boost switch wiring cable access is via a 12mm cable gland.

•

boost speed can be triggered by a switched live connection from a variety of external devices including:

- PIRFF (passive infra red)

*

- DRH240 (dynamic remote humidistat)

*

- THM (thermostat)

*

- a light switch (if more than one light switch is used,

each one must be a double pole switch)

- a remote switch/pull cord

(

*

PIRFF, DRH240 and THM may have integral over-run timer which controls the length of time that the fan

will continue to operate at its boost speed after the boost has been switched off.)

Incoming

fresh air

Cooled

outgoing

stale air

Fresh

air out

Stale

air in