Page 8

Commissioning

•

The unit operates by extracting warm, stale air from kitchens, WCs,

bathrooms etc, and passing it through a heat exchanger to the

outside. Another fan draws in cool, fresh air and passes it through the

same heat exchanger, where it heated by the outgoing, stale air (the

air flows do not mix).

•

When the unit is set up and running, the minimum setting on the

speed control switch must relate to the designed volume air flow.

The variable air flow from minimum to maximum allows the unit to

extract a greater volume to cope with any increase in the build up of

condensation or foul air, ie cooking etc.

•

Before starting the commissioning procedure, refer to the design rating for correct air flows.

N.B

extract and supply air volumes will not always be equal. When setting up, therefore, the extract system should

be the datum.

Commissioning Procedure

•

Ensure that the exhaust and supply grilles or valves are open.

•

Turn the electrical supply ON and set the fan speed control to TRICKLE.

•

Check the air flows at the grilles or valves, and adjust to suit the design figures by turning the centre of the

valve clockwise to decrease the airflow, and anticlockwise to increase the airflow.

•

If the airflow is still not correct proceed as follows:

- turn the electrical supply OFF

- remove the electrical cover

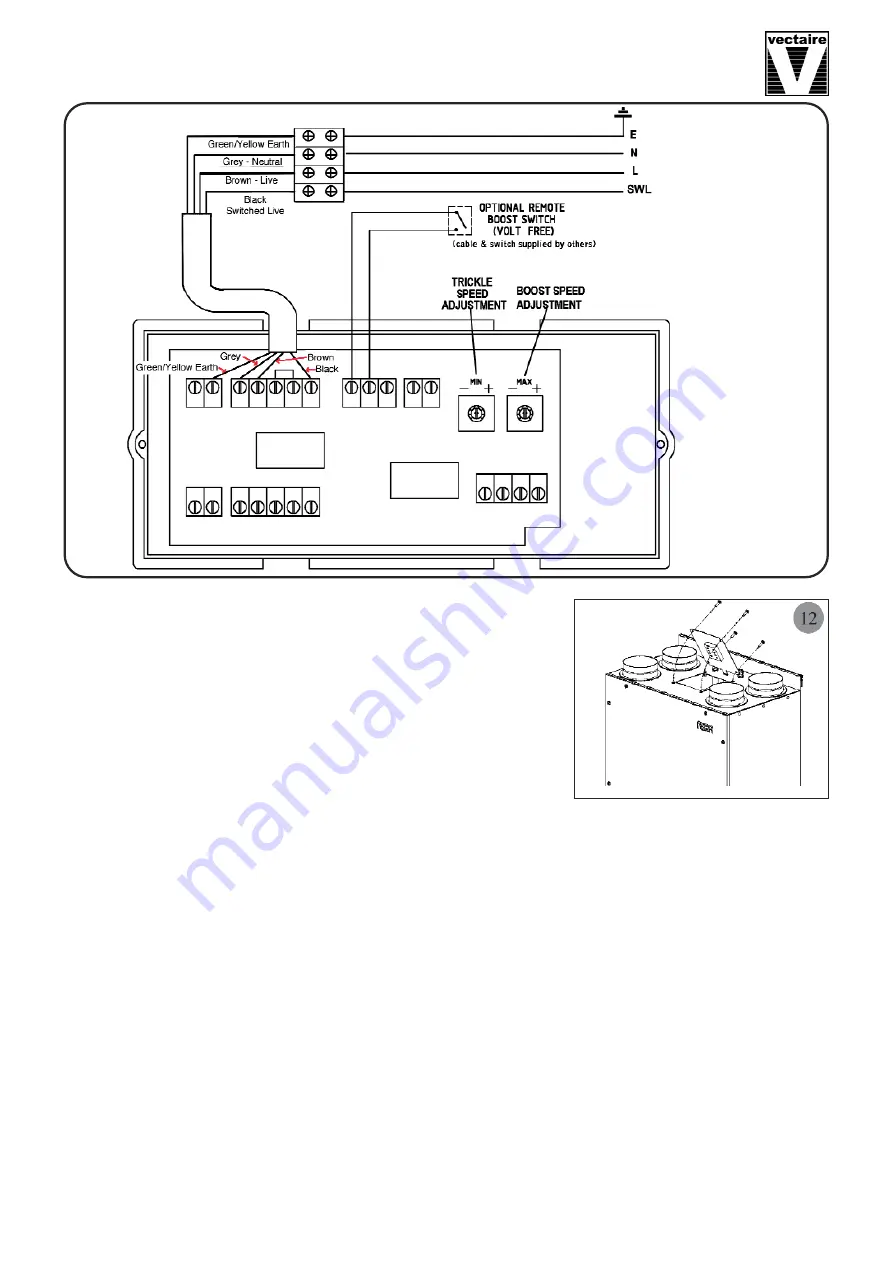

- locate the trickle speed adjustment (see Wiring Diagram above) and adjust as required.

- turn the electrical supply ON.

•

Re-measure the air flows at the grilles or valves as detailed above, and repeat the procedure until the correct

air flows are achieved.

•

Switch the fan speed to boost and ensure that airflows increase. Adjust the "Boost Speed" setting to the

desired value.