2

SPECIFICATIONS

Model

H100 / H100SF

H200 / H200SF

Motor

Pulse Jet

Pulse Jet

Chemical Tank

Polymer

Stainless steel

Tank Size

4.5L

6.5 L

Flow rate

10-50 LPH

10-50 LPH

Pressure in the chemical tank

0.224 bar

0.224 bar

Fuel

Petrol

Petrol

Performance

19 kW

19 kW

Fuel tank pressure

0.8 bar

0.8 bar

Start

Automatic (manual version available)

Automatic (manual version available)

Fuel tank capacity

1.2 L

1.2 L

Weight(net)

8.5 Kg

10.8 Kg

Dimension

112x30x35 (cm)

135x30x35 (cm)

Features

Short-circuit breaker (tank)

(Model SF : Dual Function – Fog water/oil based

Chemicals)

Short-circuit breaker (tank)

(Model SF : Dual Function – water based

chemicals as well as oil based)

Accessories

Belt, Spares Kit, Charger, Toolkit, Instruction

Manual

Belt, Spares Kit, Charger, Toolkit, Instruction

Manual

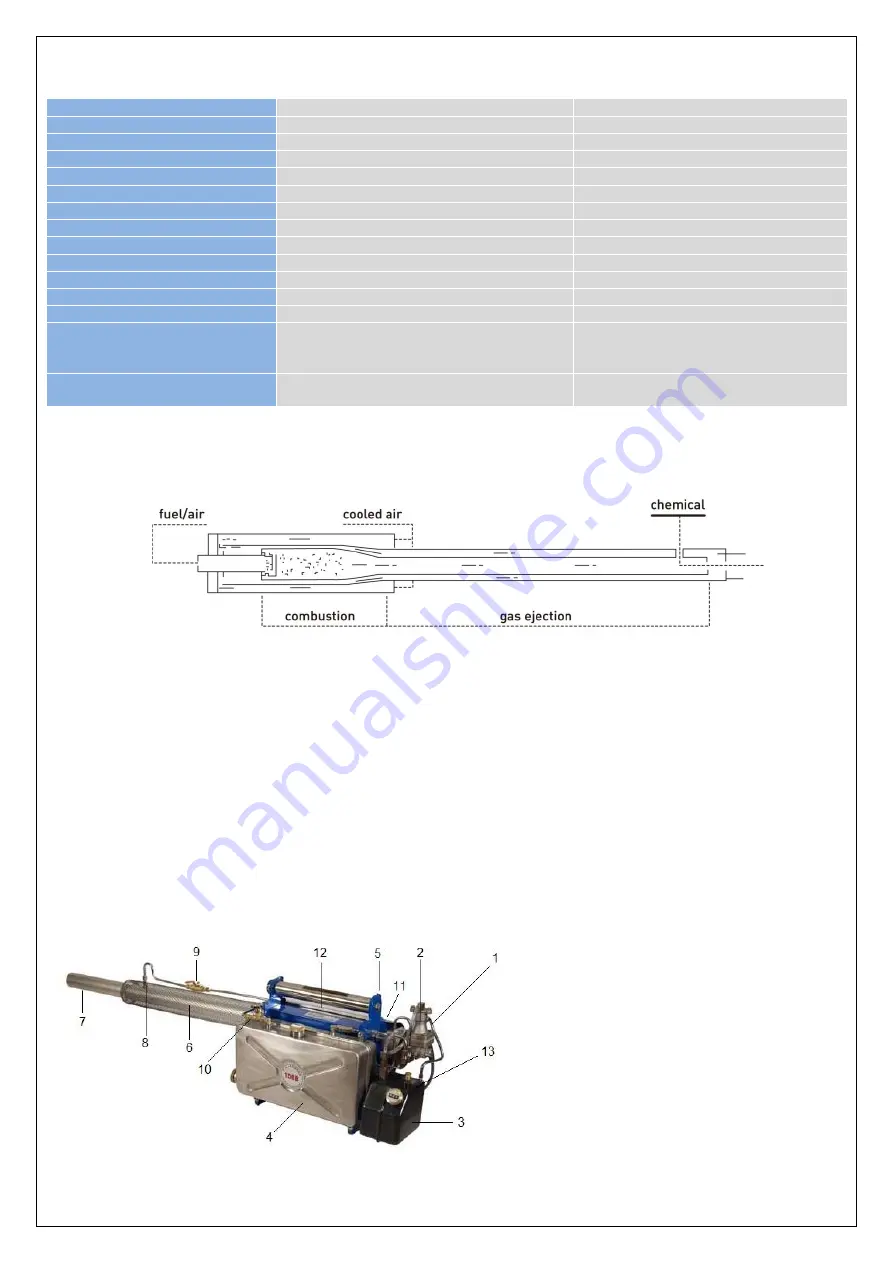

BASIC CONCEPT OF THERMAL FOGGING

VectorFog™ Thermal Foggers are powered using the pulse jet principle. Pulse jet engines don’t have any moving

parts; instead they have a funnel shaped combustion chamber similar to a rocket engine which opens into a long

resonator or exhaust pipe. VectorFog thermal foggers have an auto start and operate through compressed air via a

compressor. When the auto start button is pressed, the compressed air pressurizes the fuel tank, causing fuel to flow

to the injector and then into the carburettor. Air/fuel mixture is then ignited by a spark plug in the carburettor. The

spark is created by an ignition coil which is powered by a rechargeable battery. The ignition coil, battery and

compressor are all housed in the base of the machine. Operating at its optimum performance, combustion and

injection is repeated with a frequency of around 200-250 cycles per second. Once the machine starts, the chemical

tank also becomes pressurized by means of a non-return valve. A close valve and supply valve are then opened to

allow the flow of the chemical/oil solution in to the resonator. At this stage the solution is heated up to around 500C

and dispersed into millions of tiny droplets (around 10 microns) creating a dense and visible smoke.

1.

Fuel Injector

2.

Carburettor

3.

Fuel Tank

4.

Chemical Tank

5.

Main Body

6.

Safety Mesh

7.

Resonator

8.

Chemical Inlet

9.

Close valve/Directional valve (SF model)

10.

Chemical Supply valve

11.

Security Cover

12.

Handle/Manual Start Pump (optional)

13.

Off Button (choke)