Run

9

________________________________________________________________________________________

_______________________________________

9

-

16

This opens the Functions page. The nozzle wiper (990) can now be turned on (note the

nozzle temperature must be over 150 deg C for this to operate.

9.1.7 Loading a Glue Cartridge

Now that the tape is set and the glue settings are made a glue test can be run.

This is a manual test which is used to ensure that the glue is flowing and the tape is

feeding correctly.

Ensure a glue cartridge is loaded into the machine. This is achieved by lifting the glue

cartridge cover (970) and pulling the glue cartridge piston (972) back manually. If

sufficient of the previous cartridge is used, then a new cartridge (971) will fit inside the

chamber.

If not, close the lid and the glue piston will automatically return to push on the existing glue

cartridge when the next cycle starts.

Some glue cartridges are moulded individually and have a moulded end on one end and a

guillotined end on the other. The moulded end should be placed against the piston so that

the cartridge is held square and not able to push on an angle.

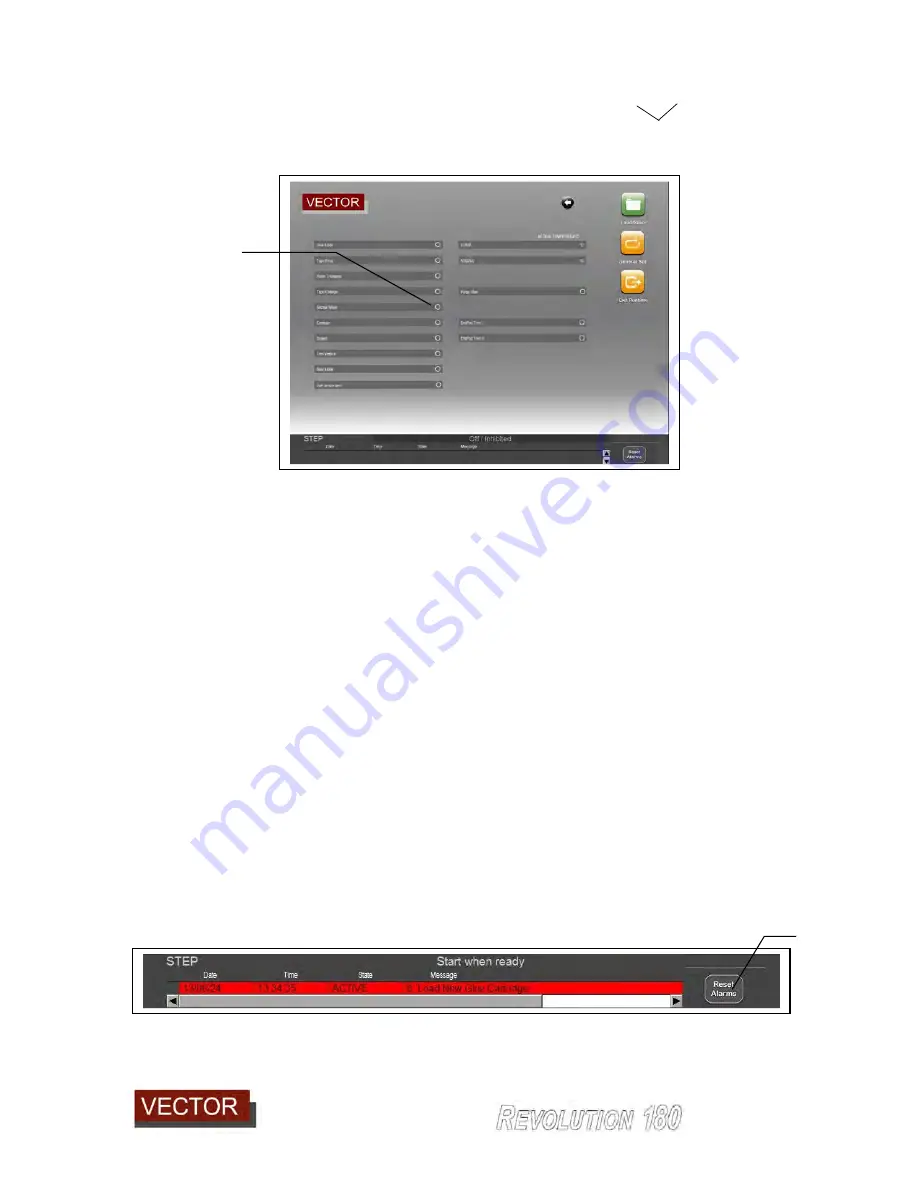

Note a proximity switch automatically detects when a new cartridge is required during a

cycle and a message

LOAD NEW GLUE CARTRIDGE

will appear on the screen. The

cycle will complete however but a new cycle will not start until a new cartridge is loaded as

per the above procedure.

When new cartridge is loaded, the alarm can be cleared by pressing Reset Alarms (974)

990

974

Summary of Contents for Revolution 180

Page 1: ...Operating Manual...