Run

9

________________________________________________________________________________________

_______________________________________

9

-

28

banding, trimming and scraping all to complete their process on the workpiece before the

head retracts and lifts.

These blocks must be the same thickness as the workpiece. This ensures that prevents

the trimmer cutters removing excess material when running onto and off of the workpiece.

This is because the outer cutter diameter is wider than the tracing shoe and as a result,

the cutter is still on the panel when the shoe is just sitting on the Start or Finish blocks. As

a result, if the block is thinner than the workpiece, the trimmer will drop down (or up – in

the case of the lower trimmer) and the trimmer will shave the panel.

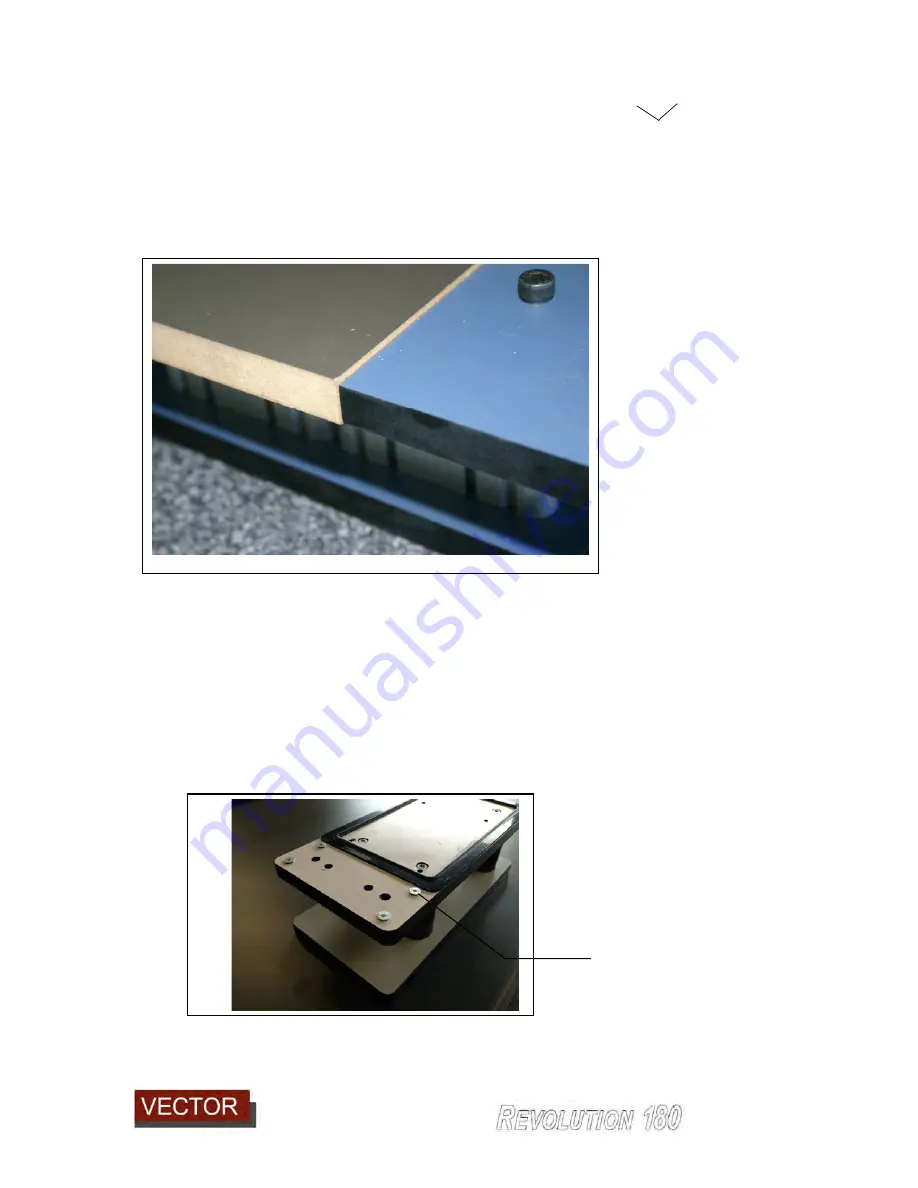

There are 4 countersunk adjusting screws (962) on the top plate in the position where the

Start/Finish plates mount. This is to allow the height of the bottom surface to be adjusted

to match the panel. Once this is done, it should not require adjustment for other panels

because the bottom reference edge is the same for all panels.

Lead block with panel butted up

against it.

NOTE: The start/finish block

must be the same thickness as

the workpiece to ensure smooth

transition of the cutters onto the

panel without damaging the

panel

The workpiece is proud of the

face of the block by up to 1mm

which ensures the band lays flat

onto the workpiece. It should

never be behind the edge of the

lead block

962

Summary of Contents for Revolution 180

Page 1: ...Operating Manual...