15.

Now install the weight stack inside

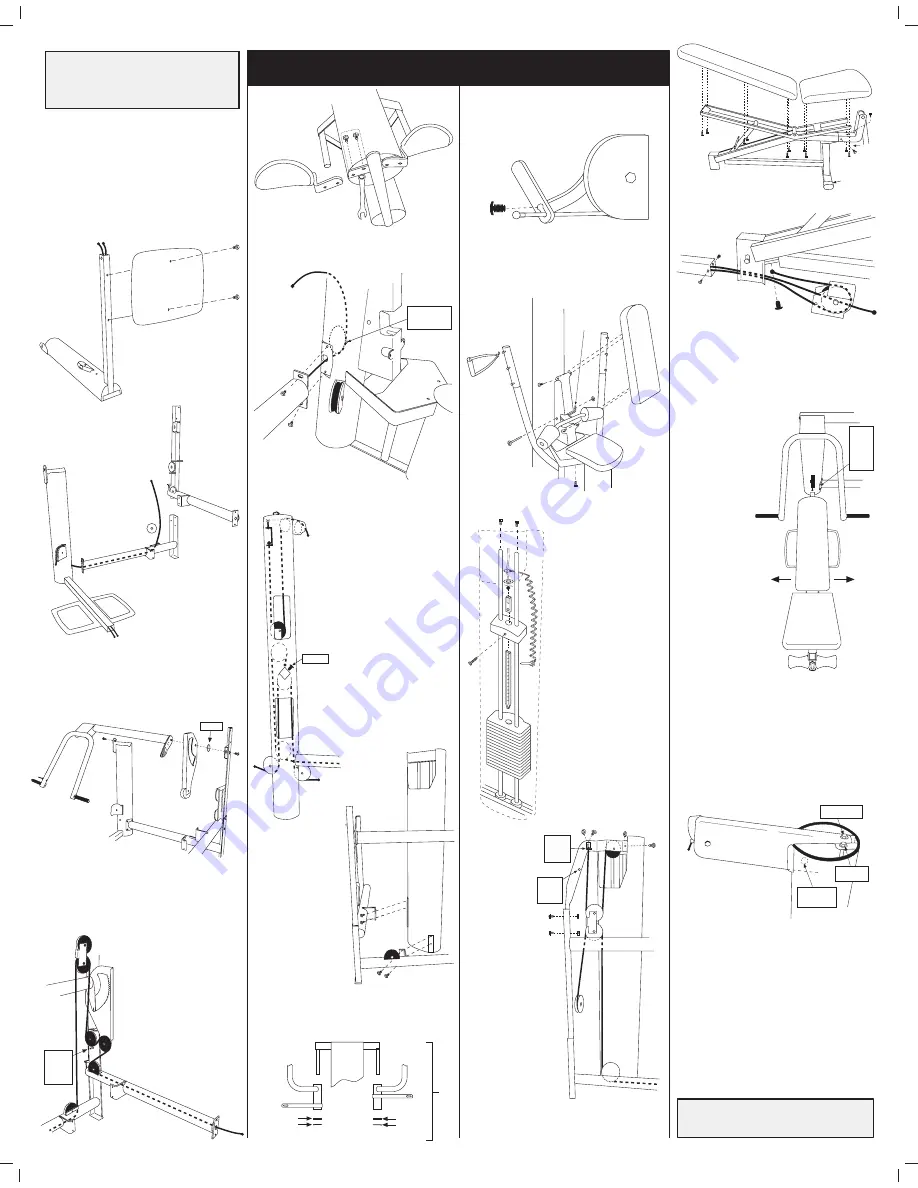

the stack column (I). Ensure that the guide

rods are in place as mentioned in step 11

above: the bottom end of each one holding

a rubber bumper and positioned over a

locator tube. Load the weight plates (15

for a 160 lbs. stack or 20 for a 210 lbs.

stack) one at a time by placing them on

the guide rods at the top of the column

with selector pin groove on the bottom

facing away from the back of the machine.

IMPORTANT:

To safely keep plates from

banging together the following procedure

is suggested: after releasing each plate,

pull the guide rods apart to slow the fall

of the plate

. DO NOT

try to catch plates

with hands or feet.

USE EXTREME

CAUTION. FIG. 12

16.

After all weight plates are in place,

assemble the top plate, selector shaft,

rubber finish washer, U-clip, and weight

pin lanyard ring to the end of the loose

cable (PN 67120), securing with 3/8-16 x

3 hex bolt. To do this, first slide the pin

lanyard ring, then rubber finish washer

onto the cable. Next, insert the cable end

into the keyhole in the U-clip. Insert the

blunt end of the selector shaft from below

into the center hole of the top plate until

it is approximately flush on top. Now

insert the U-clip ends down into the top

plate around the selector shaft end. Secure

with the cross bolt. Once the bolt is very

tight, slide the rubber finish washer onto

the cable and down onto the top of the

U-clip.

FIG. 12

6.

In this step, you

will install the press arm

(E), along with the press

adjustment plate (F) to the machine.

(large 1/2” i.d. washer, Qty: 1, and 1/2-13 x 1 button head bolts, Qty: 2).

Begin by placing the press adjustment plate onto the press arm such that

the latch pin is in one of the notches and the large hole is over the post on

the end of the press arm. Next place one of the bolts through the ball bearing

installed in the main column frame member (D). Thread the washer onto this

bolt. Now position the press arm assembly according to the diagram and

thread this bolt into the internally thread post mentioned above. Insert the

second bolt through the bearing at the top of the press post (B) and into the

press arm assembly. The press adjustment

plate should be supported in a “V” shaped

notch in the main column frame member.

Tighten the two bolts installed in this step

very tight with a 5/16” hex key.

FIG. 3

4.

Now assemble press station frame

member (C) to press post (B) (3/8-16

x 1/2 hex bolts, Qty: 4). To do this, first

route the cable exiting the side of the

press post (B) into the frame member,

down its length, around the pulley (#11)

and out. To do this it will be necessary

to temporarily remove the pulley.

Ensure that the pulley bolt is very tight

after reinstalling it. Leave the four bolts connecting the frame member to

the press post a little loose, until told to tighten them later in these instructions.

(Note: any pulley numbers mentioned in the text or shown on these drawings

correspond with the cable diagram on the other side of this manual. Refer

to that diagram as necessary during the assembly process if you’d like another

perspective.)

FIG. 2

5.

Now attach main column frame member (D) to press station frame

member (C) (3/8-16 x 3/4 hex bolts and nuts, Qty: 3 ea).

FIG. 2

If you have any questions, PLEASE

contact the full-service dealer where

you purchased this machine.

Tools Required:

Wrenches: one each 7/16”, 1/2”, and two each

9/16” end wrenches

Hex key: 5/16”

Phillips screwdriver, hammer, pliers

FIG. 1

FIG. 2

Assembly Instructions

3.

Assemble squat platform (A) to press

post (B) (3/8-16 X 1/2 hex bolts, Qty: 2).

Make sure the rubber tread on the squat

platform (A) is on the opposite side of that

shown in Fig. 1. Before proceeding, ensure

that these bolts are very tight, as tightening

them later would be difficult.

FIG. 1

1.

Select location for your machine. Set machine up in a well-lighted

and well-ventilated area where you will enjoy exercising. Use rubber floor

matting or carpet remnants to protect your floor, if desired. It is necessary

to have access to all sides of the unit during assembly. Once the unit is

assembled, it may be slid into a corner for use.

2.

Unbox entire unit, taking care to not bang parts together lifting them

from their foam supports.

(NOTE: LEAVE ALL CABLE RETAINERS IN

PLACE.)

Lay large items, such as the main column down until needed to

prevent them from accidentally falling over. To make assembly as easy as

possible, many cables are pre-routed at the factory. Route and attach cables

when the instructions call for it. After routing any cable, resecure it to prevent

it from coming unrouted before going on. Some bolts should be tightened

very tight only after the instructions say to do so. All bolts should be tight

at the end of assembly.

FIG. 3

9.

Now assemble the main

column (H) to the main column frame

member (D) (3/8-16 x 1/2 hex bolts, Qty: 2).

Before standing the main column up, route the cable

into the hole in its bracket, and around the pulley (#16) located there such

that it heads up inside the column.

IMPORTANT:

There is a small diameter

pin near this pulley. Make sure the cable

passes between the pin and the pulley. To

do this remove the lower plastic access panel

and feel under the pulley. Next stand the

main column up and bolt it to the frame

member pulling any spare cable into the

main column.

FIG. 6

10.

With both plastic access panels

removed, continue routing the cable inside

the main column (H). From pulley #16 it goes

straight up inside the main column to the

lower pulley (#17) of a double moving pulley

assembly located there. It is important that

the cable go around the lower pulley in the

correct direction to prevent twisting. First

make sure that the double moving pulley

is hanging straight down with the cables

which support it hanging straight. Route

the cable such that it goes up the rear of

the column (the side near you when looking

into the access cutouts), over pulley #17,

and then down near the front of the main

column. Terminate this cable at a single

moving pulley bracket #19 that you will

find loose inside the column. To attach it,

insert the ball end into the keyhole shaped

hole in the pulley bracket. Secure it by

inserting a plastic hole plug into the large

end of the keyhole.

Ensure that the

cables below this

pulley bracket do

not loop around the

cable going up from

pulley #16.

FIG.7

7.

Now route the cable emerging from

the press station frame member (C) as

follows: first route it around one pulley

(#12) of the double moving pulley unit (G),

next it goes under pulley #13, over pulley

#14, and then down into the main column

frame member (D) and around pulley #15.

It needs to continue along the length of

this frame member and exit through the

large round hole in the bracket welded on

its end. Place the double moving pulley

unit (G) on the floor for now.

FIG. 4

NOTE: Cable goes

between pulley #16

and this pin

H

D

16

FIG. 5

19.

Install 2 rubber feet onto bench frame (N).

Install Leg Developer Mount Assembly to Bench

Frame (3/8-16 x 3/4” hex bolts, Qty: 3). Attach the two cushions to the bench

(1/4-20 x 3/4 hex bolts, Qty: 10). Tighten pad mounting bolts firmly.

FIG. 14

11.

In preparation for attaching

the stack column (I) to the two

frame members, place the guide

rods inside. First, place a rubber

bumper (located inside of the top

plate hardware box) around the

end of each guide rod at the end

that does not have the bolt. The

two guide rods now go into the

open back of the stack column

such that the end with the rubber

bumper ends up on a locator tube

at the base of the column.

IMPORTANT:

The guide rods

need to be in stack column (I) now

because ceiling height might make

later insertion difficult or

impossible. Now assemble the

stack column (I) to the frame

members (C & D) (3/8-16 x 1/2 hex

bolts, Qty: 4) Because the stack column needs to be held off the ground to align

the holes, placing 3 or 4 layers of scrap cardboard under the stack column on

the floor will save time and effort. At this stage you may tighten the stack

column bolts and the bolts that hold the two frame members to each other.

FIG.8

13.

Connect cables to cross chest fly cam. Use plastic hole plugs in

keyholes to prevent disconnection.

FIG. 10

21.

Now that all the cable ends are

attached, the cable system may be

completed behind the stack column.

Route the cable from the stack over

the pulley (#4) on the stack column

frame member (R) and down to double

moving pulley unit (G) from step 7

above. Route the cable around pulley

#5 such that double moving pulley

unit (G) is between the stack column

and the press arm. Route the

cable around this pulley in

the direction that matches

the diagram to prevent twisted

cables. Secure the cable end to the

stack column frame member (R) at

one of the two provided attachment

points. The upper hole should be

used with the 210 lb. stack. The

lower hole should be used with

the 160 lb. stack. First remove the

small bracket with the keyhole,

insert the cable end in the keyhole,

then reattach the bracket to the

correct hole.

FIG. 13

22.

Check the press arm adjustment

lever’s operation at this point. When

the lever is operated in either direction,

the pin should retract fully, allowing

the press handle to rotate. When the

lever is released, the pin should lock

the press handle by snapping all the way into the next notch. Adjust with

phillips screwdriver if necessary. The adjustment screw is behind the stack

a few inches from the latch pin. When correctly adjusted, the latch pin will

be forced by the spring all the way against the far end of the position notch.

When operated, the adjustment lever will pull it free of the notches such that

no clicking is heard during adjustment.

It is very important

that it be adjusted

such that it goes all the way to the end of each notch with just the pressure

of the spring. There is a jam nut on the adjustment screw — tighten it against

the brass fitting to prevent the adjustment from changing over time.

23.

At this point, all assembly behind the stack is complete, and all the bolts

in that region should be tight. The machine may now be moved into a corner.

24.

Adjust the center of the bench at this point. Move it side to side

until it is centered in the press arm. Once it is centered, tighten the four bolts

securing the press station frame member (C) to the press post (B).

FIG.16

20.

Now attach the bench

assembly to the weight machine.

Align the bench hitch section

(portion with the wheel), and start it onto the

square frame, just enough such that the wheel is on the frame. Now the two

cable ends need to be attached to opposite ends of the bench. The cable end

farthest from the weight stack loops back around the larger pulley of the bench

pulley bracket (S) and attaches inside the bench hitch section near the wheel.

Insert the ball end into the keyhole and secure with a plastic hole plug. The

second cable end, the one nearer the weight stack attaches to a similar keyhole

on the leg developer cam. After inserting it, secure it with a plastic hole plug.

Next slide the bench further onto the frame and slide the bench pulley bracket

(S) back onto the frame. Secure it with the two bolts (3/8-16 x 1/2 hex bolts,

Qty: 2), tighten them firmly.

FIG. 15

25.

Adjust the high pulley member

(T) height now if necessary. Adjust it up

to provide additional pre-stretch for the

tallest user, ceiling height allowing. To do

this, loosen the bolts that pass through

pulley #2 at the top of the main column (H).

You will need two 9/16” end wrenches for

this as most other wrenches will not fit. Now tighten (or loosen if adjusting

down) the bolt on the top of the back of the high pulley member (T). Once the

chosen adjustment is reached, retighten the bolts that pass through pulley

#2. They must be very tight. The lower two frame bolts that attach the main

column frame member (D) to the main column (H) should now be tightened,

taking care to see that the base of the main column is flat on the floor.

FIG.17

26.

Tension the cable system by locating the adjustment screw on the right

of the high pulley member (T) at the top of the main column (H). Adjust the

cable tension as follows: tighten the adjustment screw until the top plate lifts

slightly. Loosen the bolt until the top plate just touches the first weight plate.

Check that the weight selector pin can be inserted in all weight plates.

FIG. 17

27.

Make sure that all cables move freely when all stations are operated.

Immediately fix any cable rubbing problems.

28.

Attach lat bar to cable at high pulley.

29.

Apply weight stack number labels per instructions printed on label

sheets. Affix the “PRESS ARM ADDS 10 lbs.” label (located on the weight

stack label sheet) to the press arm. Hang the Exercise Chart on the wall

nearby for convenient reference, frame or laminate as desired.

8.

If the optional Foot Hold-Downs

are being installed, attach them now

to the bottom of the main column (H)

(3/8-16 x 1/2 hex bolts, Qty: 4).

The bolts go from the inside of column down into the Foot Hold-Downs. They

can be tightened with a common wrench from below as shown. These may

be assembled to an upright column, but it is more difficult and requires

different wrenches. Tighten very tight before proceeding.

FIG. 5

FIG. 6

12.

Install right cross chest fly arm (J) (arm closest to stack column) on

pivot bar. The right arm is the one with the cam at the lowest point on the

arm. Install 1” washer and then cotter pin, bend end.Repeat this process

for the left arm (L).

FIG. 9

14.

Install seat bottom (N) (1/4-20x3/4 hex bolts, Qty. 2). Install the

Lat Hold-Down (O) with the lever on the right pointing up. Line up the 1/2”

holes and insert the pivot (1/2” diameter rod and shaft retainers). Install

shaft retainer with a hammer. Install seat bak (P) (1/4-20x3/4 hex bolts,

Qty. 4). Install one single handle per side (Q).

FIG. 11

17.

Now lower the

top plate assembly

down the guide rods

making sure the side

with the bolt is toward

the back of the

machine. Leave the

cable hanging out the

top of the column for

a moment and attach

the guide rods to the

support bracket at the top

of the stack column (I). To

do this remove the bolt in

the top of each guide rod,

and reinsert it through the

bracket. Make sure that the

nylon bushings are in the

top of the guide rods on top

of the threaded inserts

installed at the factory.

Tighten these bolts, and

test the guide rod spacing

by pulling the top plate to

the top of the column using

the cable. If the top plate

is sticky near the top of the

guide rods, loosen the bolts

and adjust the spacing

before proceeding.

FIG. 12

18.

Now install

the stack column frame member (R) as shown (3/8-16

x 1/2 hex bolts and nuts, Qty: 4 ea.). This frame member goes on the inside

of the angle of the main column frame member (D), not on its outside.

Tighten these four bolts very tight.

FIG. 13

I

D

C

FIG. 7

FIG. 16

FIG. 15

25

21

B

S

Hole Plug

17

19

16

20

18

2

1

3

H

FIG. 8

FIG. 9

NOTE:

These 4

bolts

adjust

bench to

press arm

alignment

E

13

14

15

11

C

D

FIG. 4

Note:

Cable goes

between

pulley #13

and this pin

LEFT CAM

DETAIL

FIG. 10

FIG. 11

N

O

P

Q

J

Lever

FIG. 12

FIG. 14

N

Rubber feet

FIG. 17

Loosen to adjust

high pulley, then

retighten.

Cable system

adjusting bolt

High pulley height

adjusting bolt

T

FIG. 13

4

5

12

13

11

Secure

cable here

for 210 lb.

stack

Secure

cable here

for 160 lb.

stack

R

G

D

A

B

B

C

D

11

Washer

E

F

D

B

RIGHT

LEFT

FR

ONT VIEW

1" Washer

Cotter pin

1" Washer

Cotter pin

J

L