16.

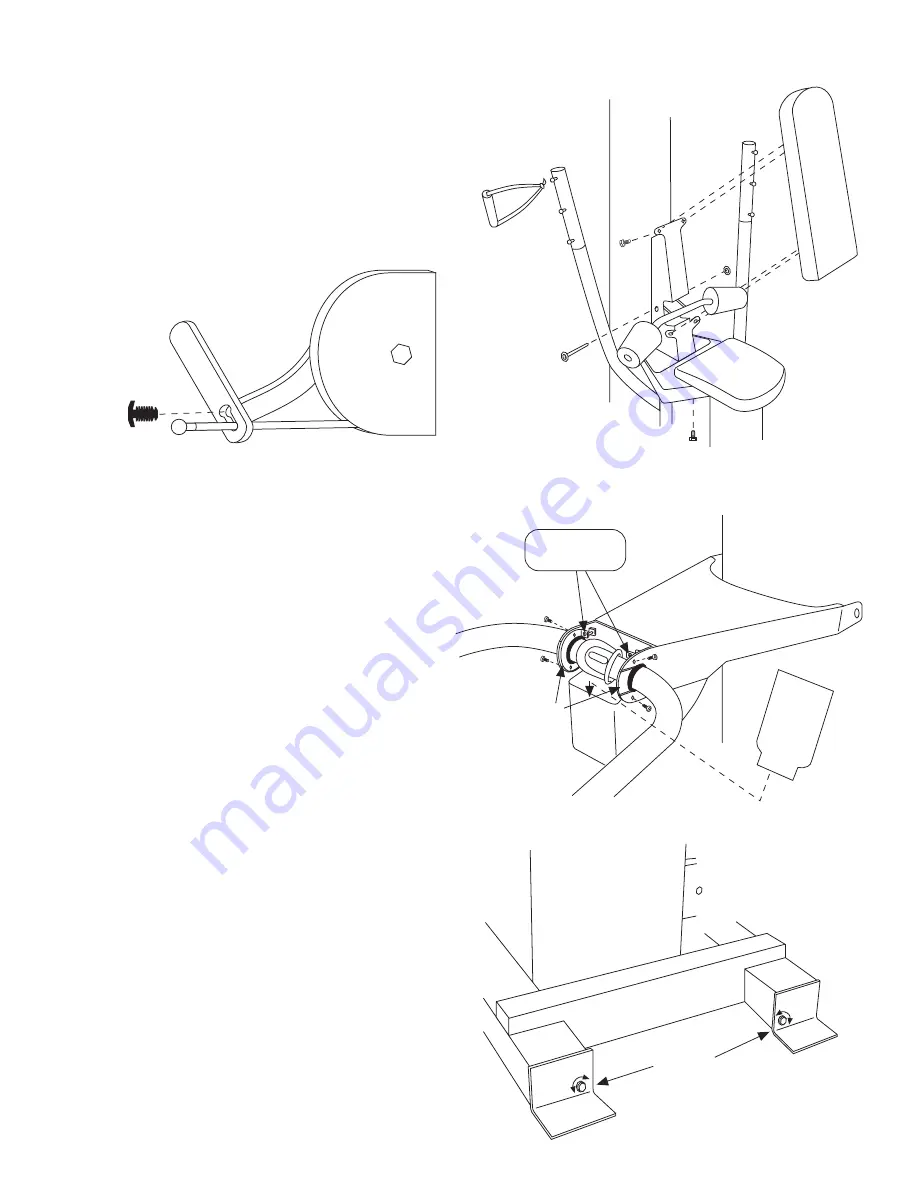

Connect cables to cross chest fly cams. Use plastic hole-plugs in keyholes

to prevent disconnection.

FIG. 10A.

17.

Install seat bottom (R) (1/4-20 x 3/4 hex screws, qty. 2). Note: If you are

installing a leg/calf press option, there are seat handles which install under

seat bottom (R). See instructions with the leg/calf press option for details. Install

the lat hold down (S) with the lever on the right pointing up. Line up the 1/2"

holes and insert the pivot (1/2" diameter rod and shaft retainers). Install shaft

retainer with a hammer. Install seat back (T) (1/4-20 x 3/4 hex screws, qty. 4).

Install one single handle per side (U).

FIG. 10.

FIG. 10

R

S

T

U

Assembly Instructions

(cont.)

FIG. 10A

LEFT CAM

DETAIL

18.

Now install press handle (V). Insert the press handle (V) into the front

of the press arm lever (I) such that the pin engages one of the notches inside

with a bracket from the press handle on each side. A nylon bushing should

be positioned (slot toward weight stack) to engage each side of the press

arm lever (I). Secure each bushing with a bushing cap (W), bent flanges up.

Install the screws in the sides (1/4-20 x 1/2 pan head phillips, qty. 4) and the

tensioning screws (1/4-20 x 1-1/4 oval head, qty. 2). Tighten the 4 side screws

finger tight. Now tighten the tensioning screws until the slop is taken up.

Do not overtighten. Once the slop is removed from the pivot, but the joint

still rotates easily, tighten the 4 cross screws. Check the adjustment

lever's operation at this point. When the lever is operated in either

direction, the pin should retract fully, allow the press handle to rotate.

When the lever is released, the pin should lock the press handle by

snapping all the way into the next notch. Adjust if necessary. When correctly

adjusted, the latch pin will be forced by the spring all the way against the far

end of the slot it travels in. The adjustment lever will pull it almost, but not

all the way, to the other end of the slot.

It is very important

that it be

adjusted such that it goes all the way to the end of the slot with the pressure

of the spring. Now install the plastic cover (X). With the textured side out,

insert the narrow end down into the front of the press arm lever (I). Curve it

back and insert the end with the hole under the top of the press arm lever (I).

The hole snaps onto a hook inside to secure it.

FIG. 11.

19.

Next adjust the position of the stack column. First make sure all

frame bolts

are very tight. Behind the stack, near the floor on each leg of the

main frame (B) you will find a bolt head. Turning either bolt head (9/16"

wrench) will move the bottom of that side of the stack column (F). Clockwise

moves the bottom of the stack back, counter-clockwise forward. Make sure

the "Mode Selection Knob" near the top of the main column (C) is in "Free

Mode." The wheels on the bottom of the press arm lever (I) will be in the "V"

of the saddle of the press arm support (A). First adjust the bottom of the stack

column to center the wheels on the press arm support (A). Once this is

accomplished, check the alignment of the "Mode Selection Knob." If it slides

into "Fixed Mode" easily, go to the next step. If it hits one side of the hole

first, more adjustment is necessary. To bring the top of the stack column (F)

toward the press station, the bottom of the stack needs to go away. Turn the

two bolt heads clockwise. Turn them an equal number of turns to keep the

press arm centered on the press arm support (A). To move the top of the stack

column back, turn the bolt heads counterclockwise.

FIG. 12.

W

TENSIONING

SCREWS

I

V

X

FIG. 11

Stack

Column

Position

Adjustment

F

B

FIG. 12