9-14

Calibration and Maintenance

CLEANING THE X-Y STAGE AND BLOCK

Contamination of the stage decreases scan performance. Therefore, whenever you see dust or dirt on

the chuck/stage assembly or on the polished aluminum block on which it rests, you must clean the

contaminated area with lint-free and abrasive-free tissues moistened with deionized water or

laboratory- grade isopropyl alcohol.

Even if you do not see visible dust or dirt, you must regularly clean the chuck/stage assembly and

block as part of preventative maintenance. Use the following guidelines for the frequency of

cleaning:

•

Whenever visible contamination is present, clean the chuck/stage assembly and polished

aluminum block before scanning.

•

If the system is in heavy use, clean the chuck/stage assembly and polished aluminum block

weekly or more frequently if environmental contamination is present.

•

If the system is in minimum use, clean the chuck/stage assembly and polished aluminum block

quarterly.

Detailed cleaning instructions appear after the Caution box.

CAUTION:

Dispose of wipes in an appropriately labelled solvent-contaminated

waste container.

ATTENTION:

Jeter les compressesde nettoyage daus une poubelle correctement

étiquettée pour les solvents.

VORSICHT:

Entsorgen Sie Alkohol-getränkte Tücher in einem dafür

vorgesehenen Behälter für Lösungsmittel abfälle.

Summary of Contents for Dektak 150

Page 1: ......

Page 7: ......

Page 17: ......

Page 81: ......

Page 105: ......

Page 149: ......

Page 191: ......

Page 251: ......

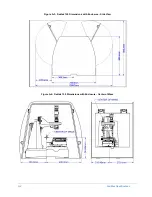

Page 257: ...A 6 Facilities Specifications Figure A 6 Dektak 150 without Enclosure Side View ...

Page 258: ...Facilities Specifications A 7 Figure A 7 Dektak 150 Dimensions without Enclosure Top View ...

Page 259: ...A 8 Facilities Specifications Figure A 8 Dektak 150 without Enclosure Center of Mass ...

Page 273: ......

Page 283: ......

Page 321: ......

Page 331: ......

Page 333: ......

Page 336: ......

Page 337: ......

Page 349: ......