DPLLD Transducer Installation

Red Jacket Standard Pumps (DPLLD w/SwiftCheck)

13

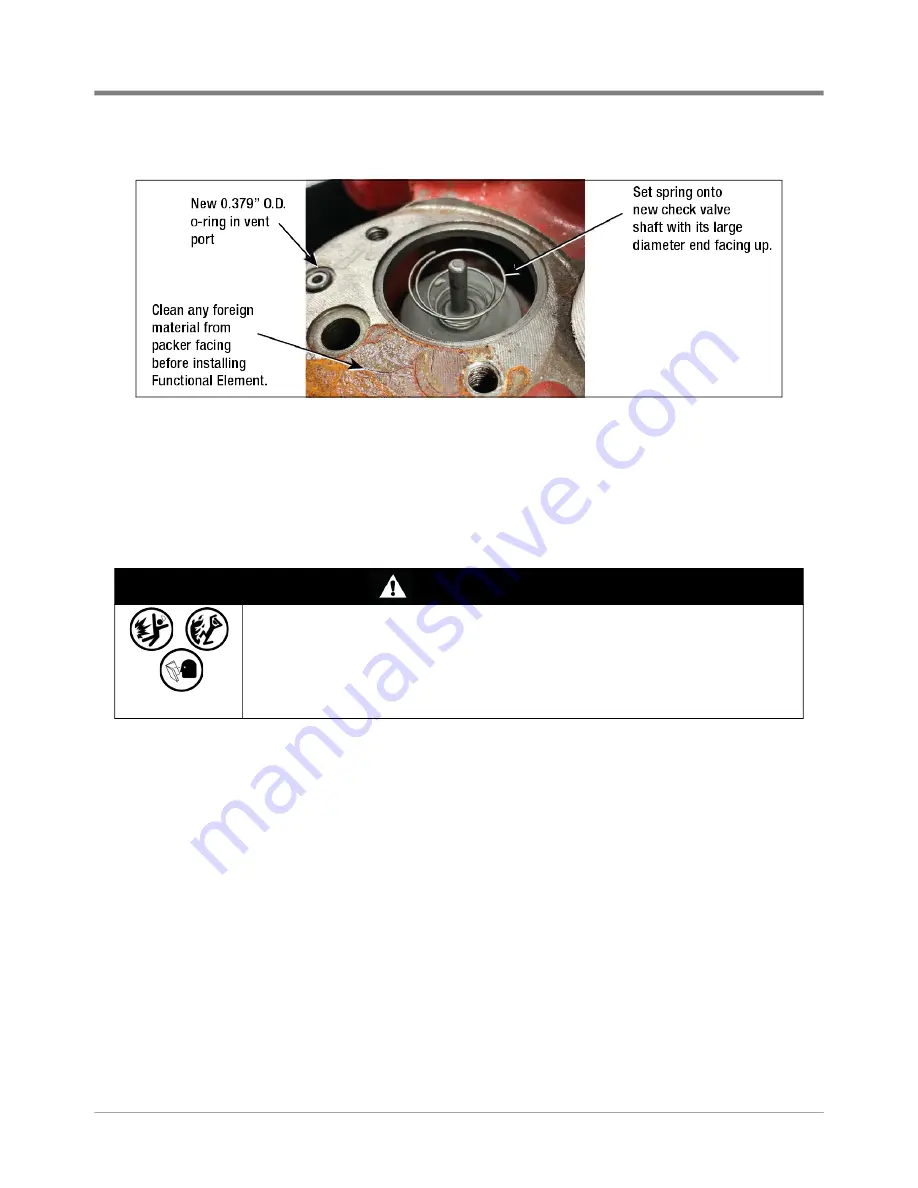

facing up. Clean the packer facing prior to installing new Functional Element.

Figure 10. Installing Check Valve And Spring In Packer

17. Carefully set the new functional element assembly in place, then install the two new 3/8-inch securing bolts

from the kit and torque to 20 - 35 ft-lb (27 - 50 N•m).

18. If siphon tubing is installed, remove the siphon plug from the new functional element. Connect the siphon

tubing fitting to the siphon port using fresh, UL classified for petroleum, non-setting thread sealant.

19. If applicable, open ball valve down line from the pump. Upon start-up of the pump, check for leaks to ensure

that the system is leak free.

WARNING

Failure to properly reseal the Functional Element may result in product

leakage, which could create serious environmental and safety hazards.

Fire, explosion, or ground contamination could occur.

Carefully reassemble and reseal the Functional Element, following the

procedures described in this manual.