23

DPLLD Wiring Connections In the Console

DPLLD Transducer Wiring Connections

• Be sure all wires are color-coded or carefully marked to identify their source and to maintain polarity.

Once a connector has been wired to a module and the console has been programmed, the

connector and module cannot be moved to another slot without reprogramming the system.

• Record the location (e.g., Line #1 (regular), Line #2 (super), etc.) of each DPLLD transducer on the circuit

directory inside the right-hand console door.

Disconnect, lock out, and tag all AC power to the TLS console, dispens

-

ers and submersible pumps.

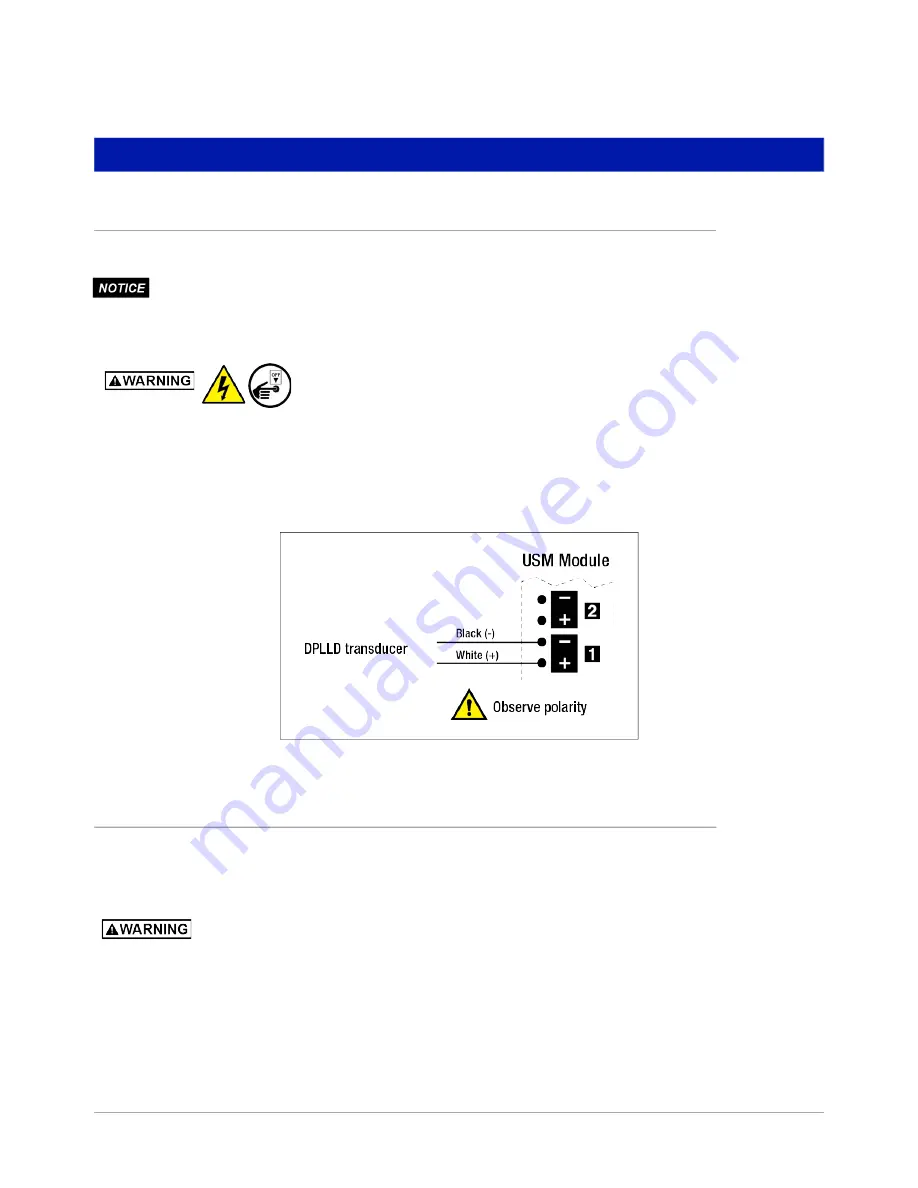

1. Connect the two color-coded or marked wires from each DPLLD transducer to the USM module. (see

19). Maintain correct polarity between the color-coded or marked field wires and the connector

terminals during wiring.

2. Connect the transducer cable’s bare wire (shield) to one of the ground lugs in the TLS console.

Figure 19. DPLLD Transducer Wiring To USM Module

Pump Wiring Connections

The console must be able to detect when dispensers are switched On or Off so it only initiates line leak tests

when the dispenser is switched Off. The console must also be able to start the submersible pump to perform a line

leak test, and shut off the pump if a leak is detected.

Dispensers and TLS console must be wired to the same leg of incoming power at the

main electrical panel; otherwise damage to both may result.

The console, when wired correctly, will control the pump independent of the dispenser

control circuits. It is imperative that when the emergency stop switch is wired and tested,

the console’s pump control circuitry CANNOT start up the pump. To ensure that the

pumps are unable to be activated in an emergency situation, have the emergency stop

switch interrupt pump power at the circuit breaker panel via shunt breakers.