10

EMR

3

- Truck Installations

EMR4 Truck Installation

3-Way Safety Valve for Truck LP Gas Systems

3.

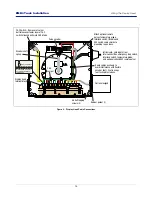

Using the wire nuts, connect the stripped wires from the IB box to the 3-way valve wires (see Figure 5). There

is no polarity to the 3-way valve’s wiring. Seal the wire nuts with epoxy sealant using one bag for both wire nut

connections and place bag in junction box (see Figure 5).

Epoxy sealant is irritating to eyes, respiratory system, and skin. Can cause allergic skin

reaction. Contains: epoxy resin and cycloaliphatic epoxycarboxylate. Precautions: Wear

suitable protective clothing, gloves, eye, and face protection. Use only in well ventilated

areas. Wash thoroughly before eating, drinking, or smoking.

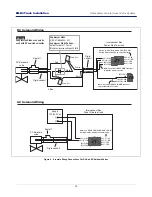

Figure 5. Connecting 3-Way Valve To Neptune Meter - Truck LP Gas Installations

4.

Tighten the cable bushing nuts on the cord grip to ensure a watertight seal at the cable’s entry.

5.

Remove the protective closures from the 3-way valve ports.

Neptune meters:

Connect a hose from line pressure to port 3 (normally open port) of the 3-way valve (see Figure 5). On some

systems, line pressure is available at an opening in the vapor eliminator housing. Connect another hose from

the 3-way valve’s port 1 (normally closed port) to the air eliminator. Connect a third hose from the 3-way

valve’s port 2 (common port) to the differential valve.

L.C./TCS Meters:

Connect a hose from the air eliminator to port 3 (normally open port) of the 3-way valve (see Figure 6). Con-

nect another hose from the 3-way valve’s port 1 (normally closed port) to the strainer cover. Connect a third

hose from the 3-way valve’s port 2 (common port) to the differential valve.

CAUTION

Rigid Met

a

l

J

u

nction Box

S

hrink wr

a

pped diode

S

hielded 2-Wire C

ab

le

V-R PN

8

4

8

100-250

Cord Grip

V-R PN

33

102

8

-001

Port 1

(N.C.)

Port

3

(N.O.)

Port 2

(COM)

Ho

s

e Connection

s

are 1/4'' NPT

Connect to Line

Pre

ssu

re

Connect to

Differenti

a

l

V

a

lve

12 Vdc 10 W

a

tt

s

3

-W

a

y

S

olenoid V

a

lve

Connect to

Air Elimin

a

tor

Connect wire

s

in IB

u

nit

1/2'' NPT

Nipple or Cond

u

it

75

8

-2

3

.ep

s

Bl

a

ck

White (+)

To

3

-W

a

y

v

a

lve

To

IB

u

nit

Red

Red

Wire n

u

t

s

In

s

truction

s

:

NOTE: When temper

a

t

u

re i

s

b

elow 50°F (10°C), keep

re

s

in in

a

w

a

rm pl

a

ce prior to mixing (e.g., in

a

n in

s

ide

pocket next to

b

ody).

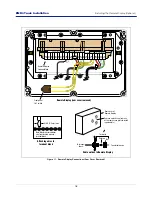

1. Att

a

ch red wire

s

from

3

-w

a

y v

a

lve to

b

l

a

ck

a

nd white

(+) wire from IB

u

nit with wire n

u

t

s

as

s

hown in A.

Connect diode white wire to red/white (+) p

a

ir.

Connect diode

b

l

a

ck wire to red/

b

l

a

ck p

a

ir.

2. Open epoxy p

a

ck

a

ge,

a

nd remove re

s

in p

a

k.

3

. Holding

re

s

in p

a

k

as

s

hown in B,

b

end p

a

k

a

long long

length.

4. A

s

s

hown in C, firmly

squ

eeze the RED

S

IDE of the

re

s

in, forcing it thro

u

gh the center

s

e

a

l

a

nd into

BLACK

S

IDE.

5. Mix thoro

u

ghly to

a

u

niform color

b

y

squ

eezing

content

s

ba

ck

a

nd forth 25-

3

0 time

s

.

6.

Squ

eeze mixed, w

a

rm re

s

in into one end of

ba

g

a

nd

c

u

toff other end.

7.

S

lowly in

s

ert wiring connection

s

into

s

e

a

ling p

a

ck

u

ntil

they fit

s

n

u

gly

a

g

a

in

s

t the oppo

s

ite end.

8

. Twi

s

t open end of

ba

g

a

nd

us

e tie wr

a

p to clo

s

e it off,

or wr

a

p open end of

ba

g with vinyl electric

a

l t

a

pe (not

incl

u

ded)

a

nd po

s

ition the t

a

ped end

u

p

u

ntil the re

s

in

jell

s

.

9. Pl

a

ce epoxy p

a

ck into j

u

nction

b

ox

a

nd

s

crew on

cover

as

s

hown in D.

C

A

D

B

Diode

(+)